| –

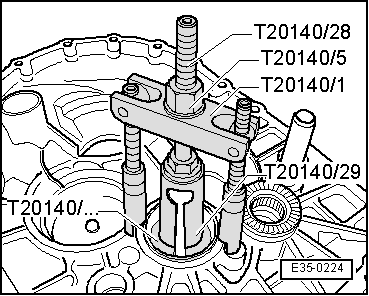

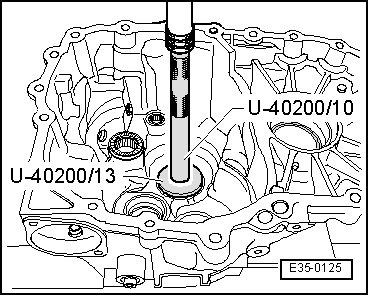

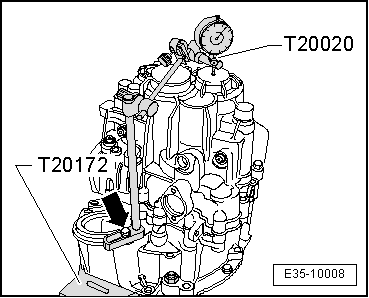

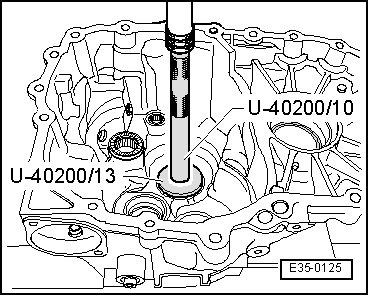

| Fit the measurement tools and secure them with a bolt -arrow- in the clutch housing. |

| –

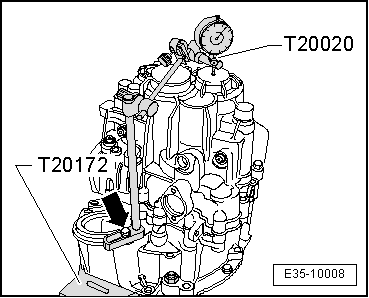

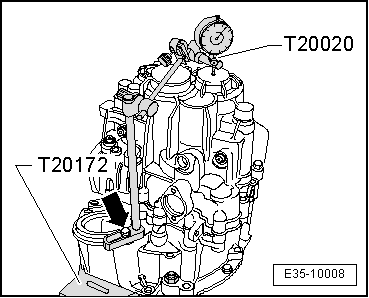

| Fit the support -T20020- and measurement tools securing them to the clutch housing with the bolt -arrow-. |

| –

| Put the dial gauge (3 mm range) to “0” with a pretension of 1 mm. |

| –

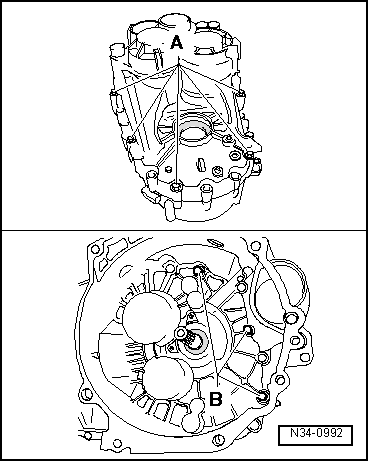

| Loosen, diagonally, the bolts securing the clutch housing to the gearbox until the gearbox housing or the secondary shaft may be lifted. |

| –

| Read the value indicated by the dial gauge and note it (in the example: 0.25 mm). |

Note | When loosening the bolts securing the clutch housing to the gearbox, no value is indicated on the dial gauge, the shim of 1.95 mm or that of 2.20 mm must be fitted to make the measurement. |

| Determining thickness of shims |

| The specified bearing preload is attained by subtracting the measured value (0.25 mm) from the inserted shim (1.70 mm) and adding a constant value for preload (0.20 mm). |

|

|

|

Note

Note