Leon Mk1

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

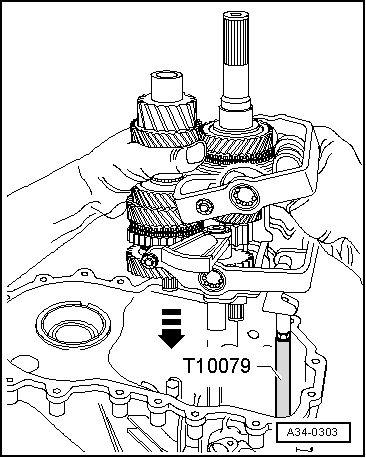

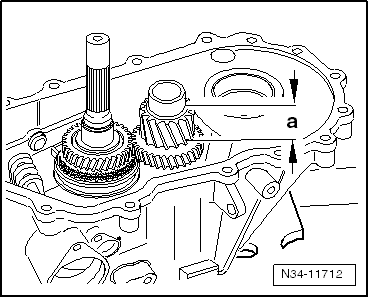

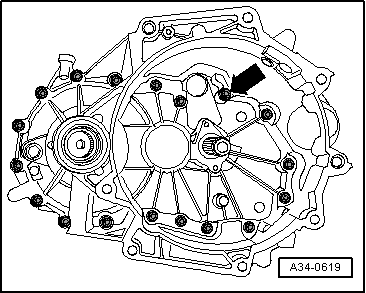

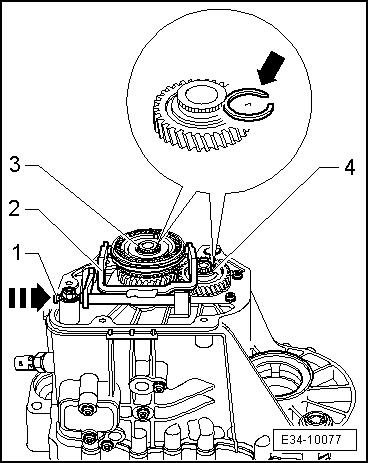

| Dimension -a- = 30.6 mm | |

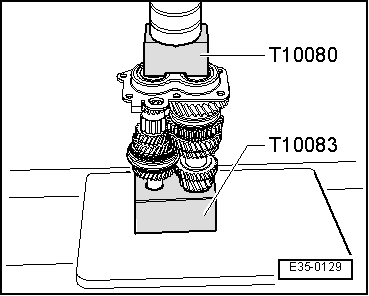

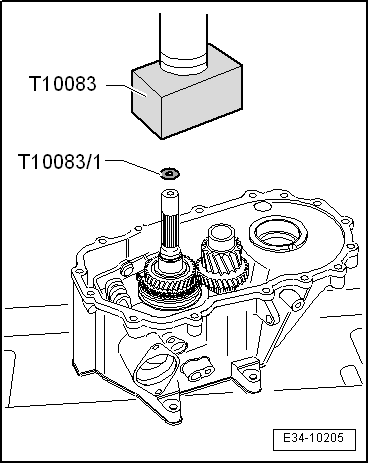

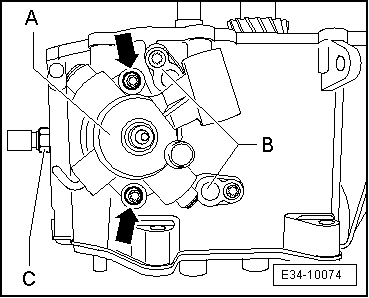

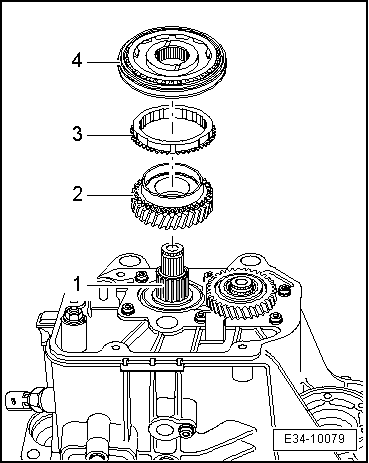

| Place the washer -T10083/1- on the input shaft → Fig. |

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

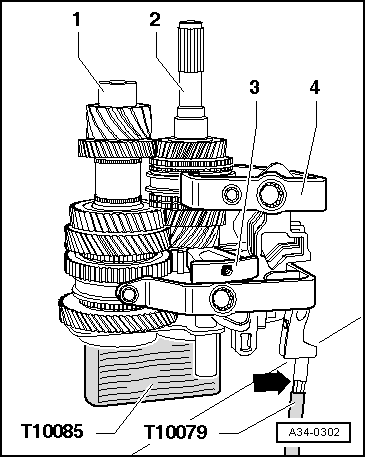

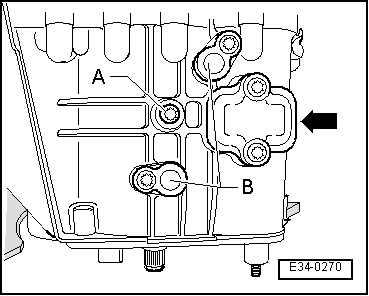

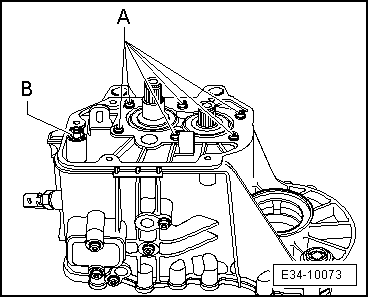

| Thickness (mm) | |

| 2,00 | 2,10 |

| 2,20 | |

|

|

|

WARNING

WARNING