Leon Mk1

Note

Note

|

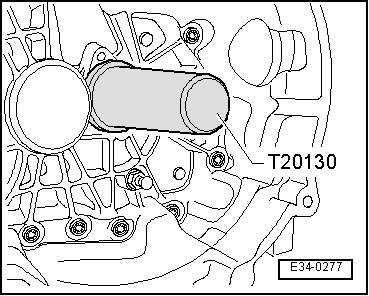

| 1 - | Grommet |

| q | For selector shaft |

| q | Driving out → Fig. |

| q | Driving in → Fig. |

| 2 - | Dowel sleeve |

| 3 - | Magnet |

| q | Supported by the separation surface of the housing |

| 4 - | Sealing cap |

| q | Apply sealing compound → Electronic spare parts catalogue „ETKA“. |

| q | Before tightening, evenly apply a sealing paste on the sealing surface. |

| 5 - | Circlip |

| q | Insert in groove of cylindrical roller bearing → Item. |

| 6 - | Circlip |

| q | Insert in groove of cylindrical roller bearing → Item. |

| 7 - | Cylindrical roller bearing |

| q | For input shaft |

| q | Remove → Fig. |

| q | Driving in → Fig. |

| 8 - | Cylindrical roller bearing |

| q | For output shaft |

| q | Remove → Fig. |

| q | Driving in → Fig. |

| 9 - | clutch housing |

| q | If replaced, adjust the differential → Chapter |

| 10 - | Join ring for the input shaft |

| q | removing and fitting → Chapter |

| 11 - | Ball head stud |

| q | 20 Nm |

| q | Grease all of the contact points with the spherical pivot and all the contact surfaces with lubricating grease, according to → Electronic spare parts catalogue „ETKA“. |

| 12 - | Left flanged shaft seal: |

| q | This may be replaced with the gearbox in place → Chapter |

| 13 - | Grommet |

| q | For oil seal. |

| q | Remove → Fig. |

| q | Driving in → Fig. |

| 14 - | Bolt |

| q | For oil filler plug |

| q | Tightening torque → Chapter |

| 15 - | Shim S2 |

| q | For differential |

| q | Determining thickness → Chapter |

| 16 - | Outer ring of roller bearing |

| q | For differential |

| q | Removing and installing → Chapter |

| q | If replaced, adjust the differential → Chapter |

| 17 - | Bolts |

| q | 5 Nm + further 1/4 (90°) |

| q | replace |

| 18 - | Outer ring of roller bearing |

| q | For differential |

| q | Removing and installing → Chapter |

| q | If replaced, adjust the differential → Chapter |

| 19 - | Shim S1 |

| q | For differential |

| q | Always 1 mm thick |

| q | The shim S1 is no longer installed in gearboxes from manufacturing date 49.2006 → Fig. |

| q | The bearing seat for tapered roller bearing outer race in the gearbox casing has been adapted. |

| 20 - | Dowel sleeve |

| 21 - | Gearbox |

| q | The shim S1 is no longer installed in gearboxes from manufacturing date 49.2006 → Fig. |

| q | The bearing seat for tapered roller bearing outer race in the gearbox casing has been adapted. |

| q | If replaced, adjust the differential → Chapter |

| 22 - | Bolt |

| q | For the oil filler hole |

| q | Tightening torque → Chapter |

| 23 - | Left flanged shaft seal: |

| q | This may be replaced with the gearbox in place → Chapter |

|

|