Leon Mk1

| Adjusting 2nd and 4th gear brake -B2- |

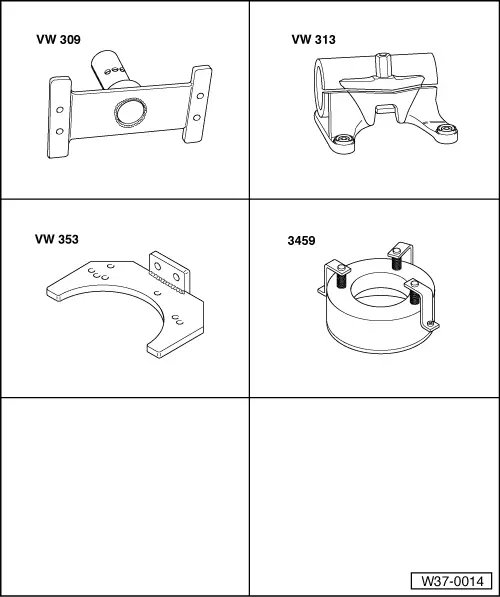

| Special tools and workshop equipment required |

| t | Support plate -VW 309- |

| t | Support clamp -VW 313- |

| t | Gearbox support -VW 353- |

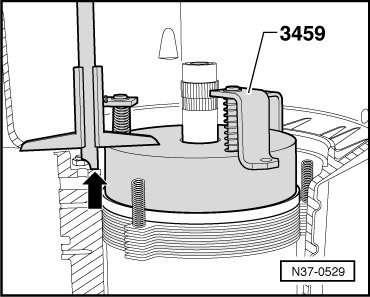

| t | Adjusting device -3459- |

| t | Depth gauge |

| t | Straight edge |

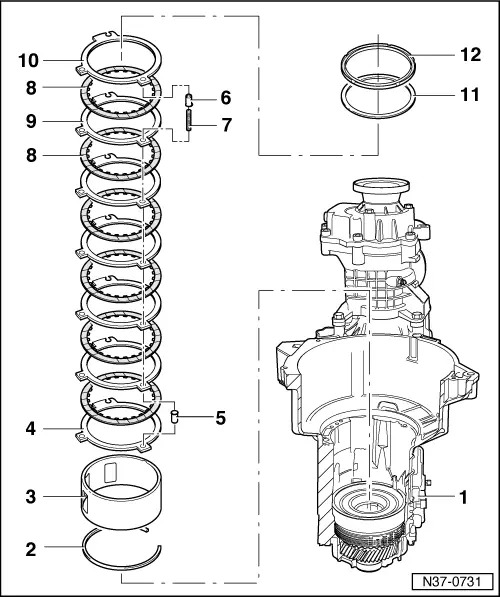

| These adjusting instructions only apply to gearboxes in which a shim and a retaining ring are installed in brake -B2- → Item and → Item. |

| In these gearboxes, the play of brake -B2- is determined by the thickness of the shim. |

| In some gearboxes, a corrugated washer is installed on the last outer disc instead of the retaining ring. |

| The play of brake -B2- is determined by the thickness of the last outer disc. |

| Adjusting instructions for such gearboxes → Chapter. |

| – | Install components for adjusting without shim → Item, without last outer disc → Item and without spring caps → Item. |

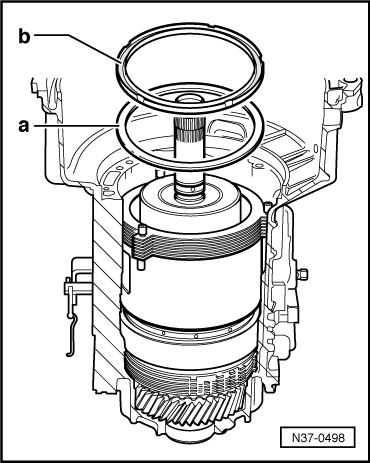

| 1 - | Gearbox housing |

| 2 - | Circlip |

| q | For supporting tube. |

| 3 - | Supporting tube -B2- |

| q | Replacement parts are allocated according to gearbox code letters → Electronic parts catalogue “ETKA”. |

| q | Inserting so that notch locates on freewheel wedge. |

| 4 - | Outer disc -B2- |

| q | 3 mm thick. |

| 5 - | Spring cap |

| q | Installing after installing first outer disc → Item. |

| 6 - | Spring cap |

| q | Do not install when adjusting -B2-. |

| q | Installing before installing last outer disc. |

| 7 - | Spring |

| q | Replacement parts are allocated according to gearbox code letters → Electronic parts catalogue “ETKA”. |

| 8 - | Inner disc -B2- |

| q | Quantity → Chapter. |

| q | Replacement parts are allocated according to gearbox code letters → Electronic parts catalogue “ETKA”. |

| 9 - | Outer disc -B2- |

| q | Always installing 2 mm thick outer discs. |

| q | Quantity → Chapter. |

| 10 - | Outer disc -B2- |

| q | 3 mm thick. |

| q | Do not install when adjusting -B2-. |

| 11 - | Shim |

| q | Do not install when adjusting -B2-. |

| 12 - | Retaining ring |

| q | Inserted with smooth side facing last inner disc → Item when adjusting -B2-. |

|

|

|

|

|

|

|

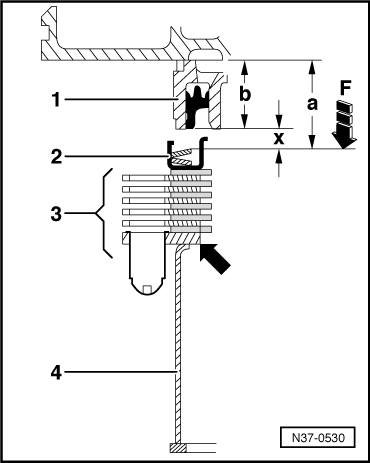

| Height of -3459- | = | 60.0 mm |

| - Measured value | = | - 32.3 mm |

| Calculated value a | = | 27.3 mm |

|

|

|

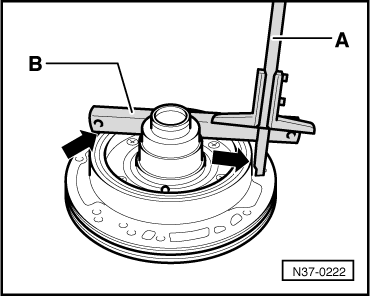

| Measured value | = | 39.8 mm |

| - Straight edge | = | - 19.5 mm |

| Calculated value b | = | 20.3 mm |

|

| Gap “x” (mm) | Shims (mm) |

| 3.25 … 3.50 3.51 … 3.75 3.76 … 4.00 | 1.0 1.25 1.50 |

| 4.01 … 4.25 4.26 … 4.50 4.51 … 4.75 | 1.75 1.00 + 1.00 1.00 + 1.25 |

| 4.76 … 5.00 5.01 … 5.25 5.26 … 5.50 | 1.25 + 1.25 1.25 + 1.50 1.50 + 1.50 |

| 5.51 …5.75 5.76 …6.00 | 1.50 + 1.75 1.75 + 1.75 |

|

|

|