Leon Mk1

|

|

|

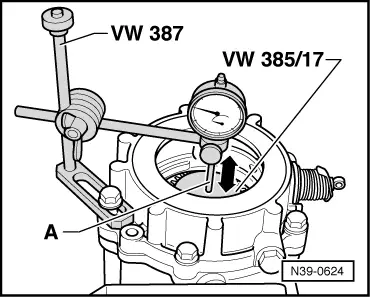

| Shim | 1.00 mm | |

| + | Preload (constant) | 0.30 mm |

| + | Play (read off dial gauge) | 0.90 mm |

| Stotal = | 2.20 mm | |

|

| New bearings | Used bearings → Note |

| 200 … 250 Ncm | 30 … 50 Ncm |

|

|

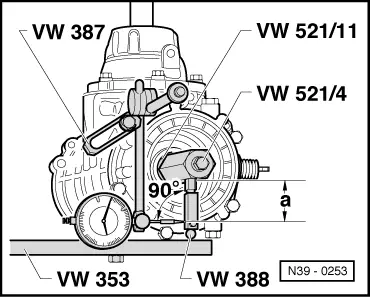

| 1st measurement | 1.30 mm | ||

| + | 2nd measurement | 1.31 mm | |

| + | 3rd measurement | 1.30 mm | |

| + | 4th measurement | 1.29 mm | |

| Total | 5.20 mm | ||

|

| S2 | = | Inserted shim (Stotal) |

| - | Average backlash | |

| + | Lift (constant value) Lift = 0.20 mm |

| Example: | ||

| Inserted shim | 2.20 mm | |

| - | Average backlash | 1.30 mm |

| 0.90 mm | ||

| + | Lift (constant value) | 0.20 mm |

| S2 | = | 1.10 mm |

|

| Thickness (mm) | Part no. |

| 0.65 0.70 0.75 | 02B 409 210 02B 409 210 A 02B 409 210 B |

| 0.80 0.85 0.90 | 02B 409 210 C 02B 409 210 D 02B 409 210 E |

| 0.95 1.00 1.05 | 02B 409 210 F 02B 409 210 G 02B 409 210 H |

| 1.10 1.15 1.20 | 02B 409 210 J 02B 409 210 K 02B 409 210 L |

| 1.25 1.30 1.35 1.40 | 02B 409 210 M 02B 409 210 N 02B 409 210 P 02B 409 210 Q |

|

| Thickness (mm) | Part no. |

| 0.65 0.70 0.75 | 02D 409 247 02D 409 247A 02D 409 247B |

| 0.80 0.85 0.90 | 02D 409 247C 02D 409 247D 02D 409 247E |

| 0.95 1.00 1.05 | 02D 409 247F 02D 409 247G 02D 409 247H |

1.10 1.15 1.20 | 02D 409 247J 02D 409 247K 02D 409 247L |

| 1.25 1.30 1.35 | 02D 409 247M 02D 409 247N 02D 409 247P |

| 1.40 | 02D 409 247Q |

|