Leon Mk1

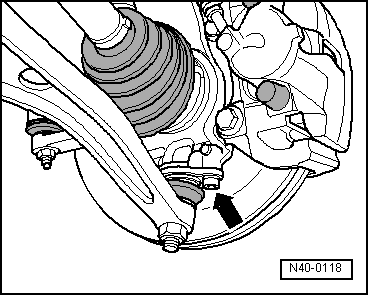

| Removing and installing front left flange shaft oil seal |

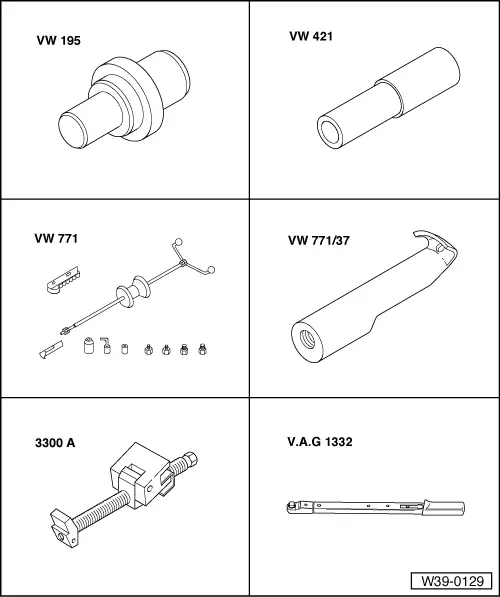

| Special tools and workshop equipment required |

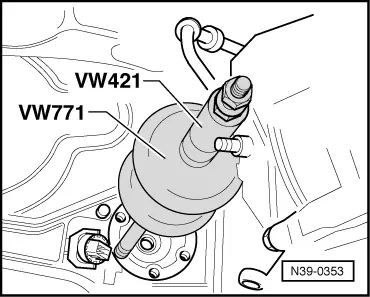

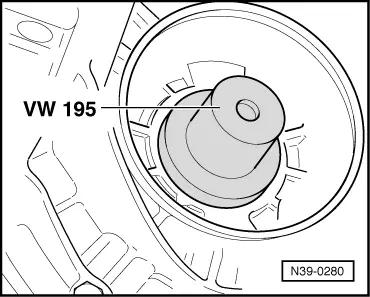

| t | Drift -VW 195- |

| t | Tube -VW 421- |

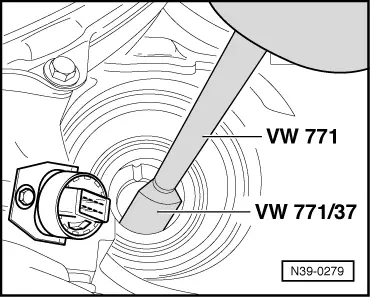

| t | Multi-purpose tool -VW 771- |

| t | Extra piece -VW 771/37- |

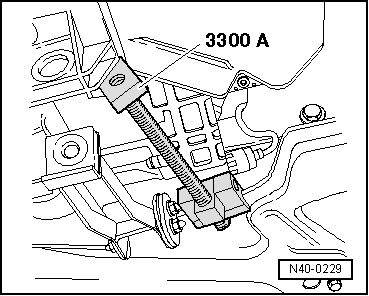

| t | Engine support -3300 A- |

| t | Torque wrench -V.A.G 1332- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

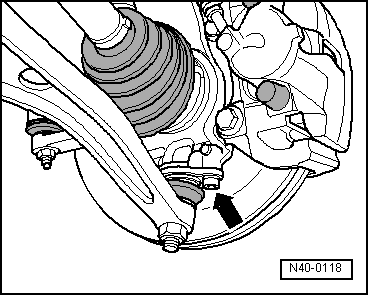

| Drive shaft to drive flange | 80 Nm | ||

| Wheel bearing housing to lower swivel joint | 55 Nm | ||

Hexagon bolt on drive shaft

| 150 Nm + 90° | ||

| Coupling rod on anti-roll bar | 100 Nm | ||

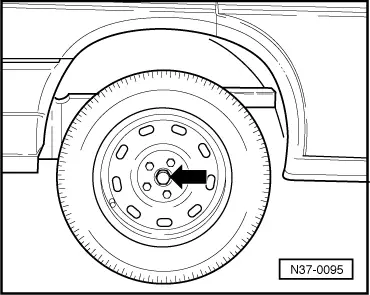

| Wheel bolts to wheel hub | 140 Nm |