Leon Mk1

|

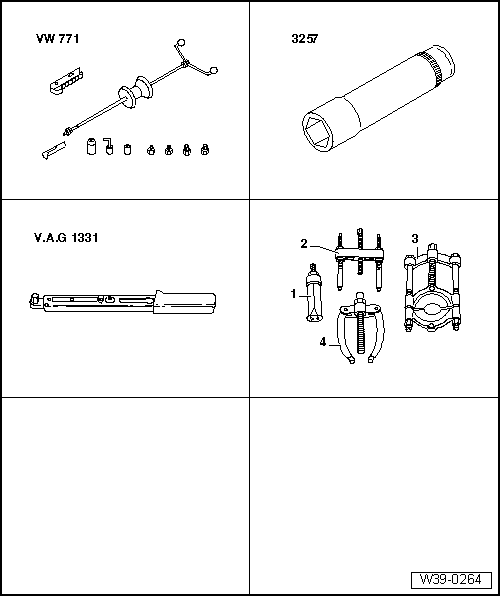

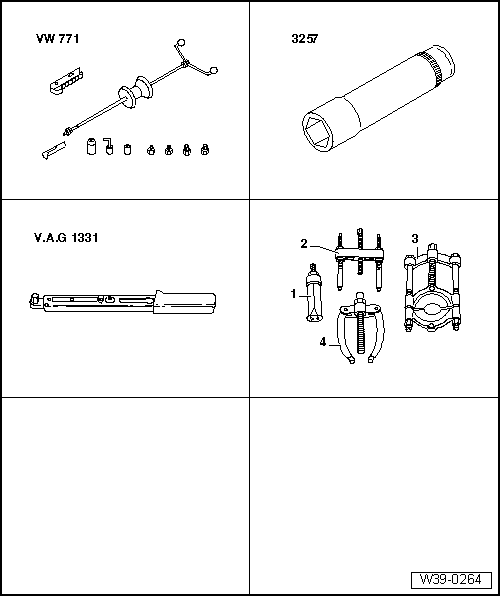

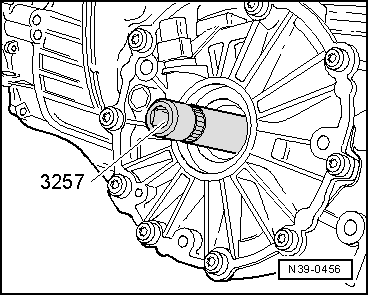

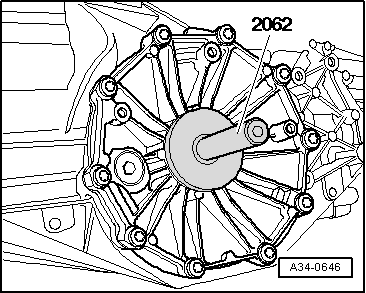

| Special tools and workshop equipment required |

| t | Universal tool -VW 771- |

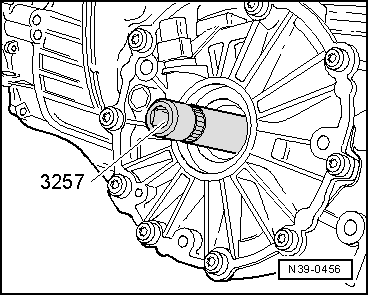

| t | Socket (27 mm) -3257- |

| t | Torque wrench -V.A.G 1331-, see equivalent → Anchor. |

| t | -1-Interior extractor -Kukko 21/5- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Special tools and workshop equipment required |

| t | Universal tool -VW 771- |

| t | Socket (27 mm) -3257- |

| t | Torque wrench -V.A.G 1331-, see equivalent → Anchor. |

| t | -1-Interior extractor -Kukko 21/5- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|