Leon Mk1

|

| Special tools and workshop equipment required |

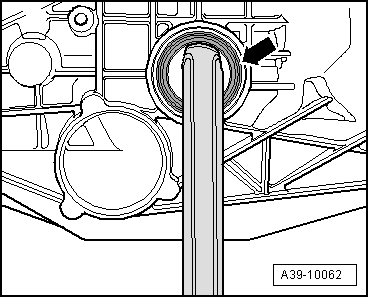

| t | Mandrel -VW 295- |

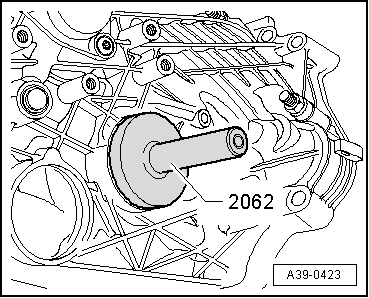

| t | Punch -2062- |

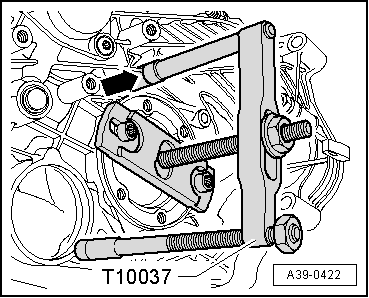

| t | Extractor -T10037- |

| t | Collecting tray -V.A.G 1306-, see equivalent → Anchor |

| t | Torque wrench -V.A.G 1331-, see equivalent → Anchor. |

| t | Torque wrench -V.A.G 1332-, see equivalent → Anchor. |

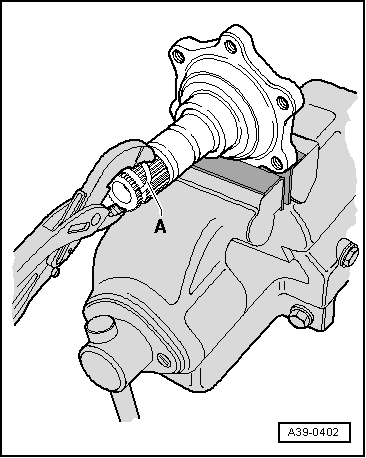

| t | Sealing grease -G 052 128 A1- |

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

| Component | Nm | |

| Heat shield above drive shaft to gearbox | 23 | |