Leon Mk1

| Adjusting differential |

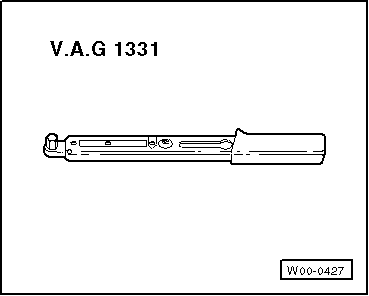

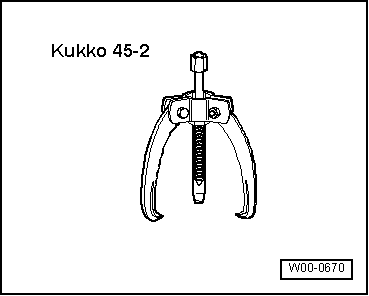

| Special tools and workshop equipment required |

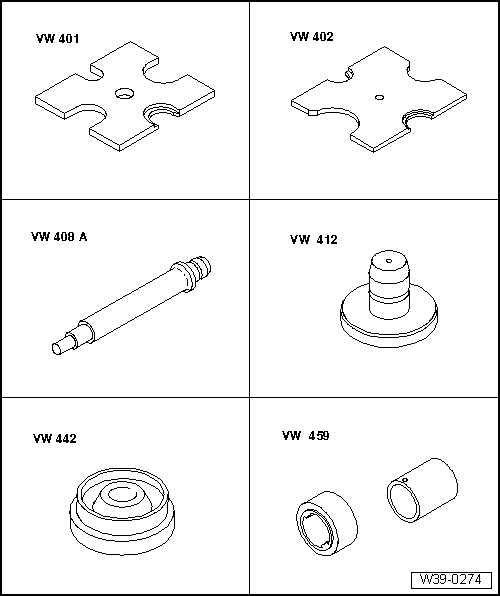

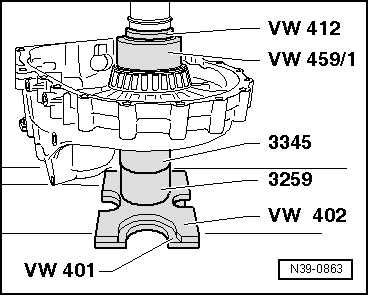

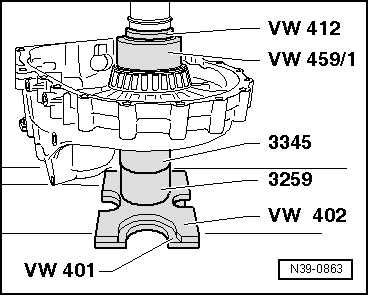

| t | Thrust plate -VW 401- |

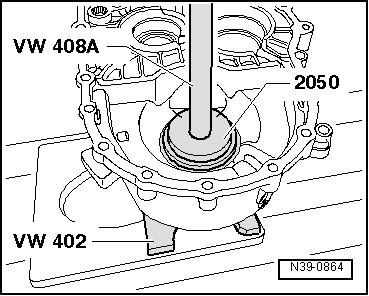

| t | Thrust plate -VW 402- |

| t | Press tool -VW 408 A- |

| t | Press tool -VW 412- |

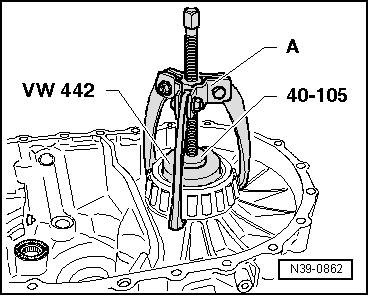

| t | Thrust piece -VW 442- |

| t | Removal and installing tool -VW 459/1- |

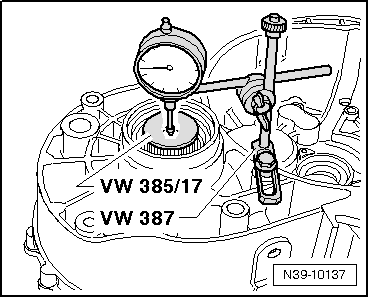

| t | End dimension plate -VW 385/17- |

| t | Universal dial gauge bracket -VW 387- |

| t | Thrust plate -40-105- |

| t | Thrust piece -2050- |

| t | Tube -3259- |

| t | Tube -3345- |

|

|

|

|

|

|

|

|

Note!

Note!

|

|

|

|

| Measured value | 0.70 mm | |

| + | Preload (constant value) | 0.30 mm |

| Thickness of shim = | 1.00 mm |

|

|

|

| Shim thickness (mm) | |||

| 0.65 | 0.85 | 1.05 | 1.25 |

| 0.70 | 0.90 | 1.10 | 1.30 |

| 0.75 | 0.95 | 1.15 | 1.35 |

| 0.80 | 1.00 | 1.20 | 1.40 |

|

|

|