Leon Mk1

| Adjusting output shaft for 5th, 6th and reverse gears |

| (Determining shim for output shaft) |

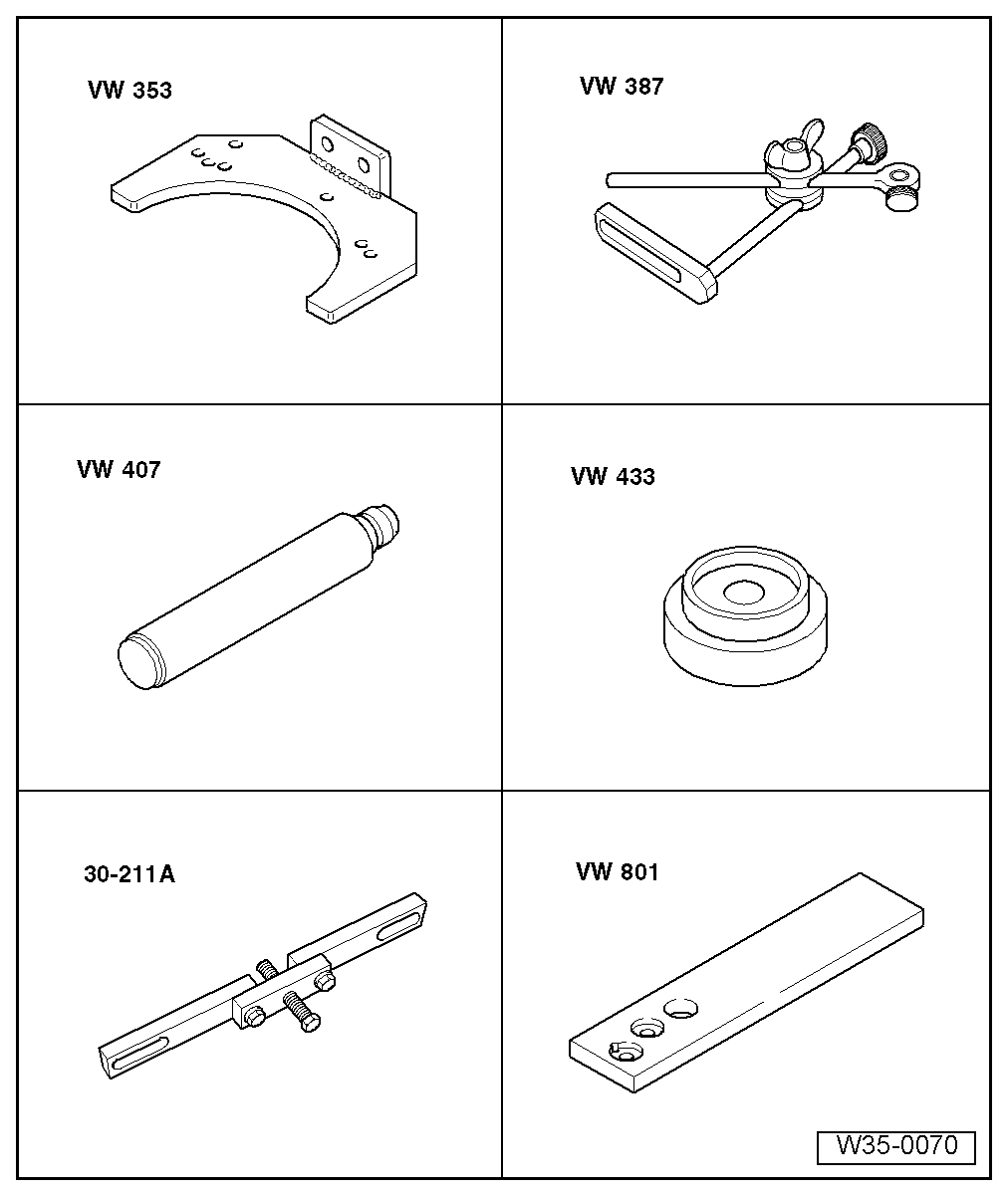

| Special tools and workshop equipment required |

| t | Gearbox support -VW 353- |

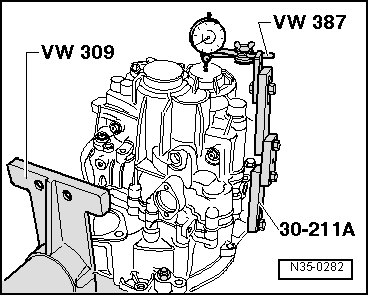

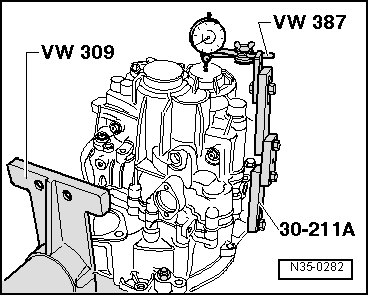

| t | Universal dial gauge bracket -VW 387- |

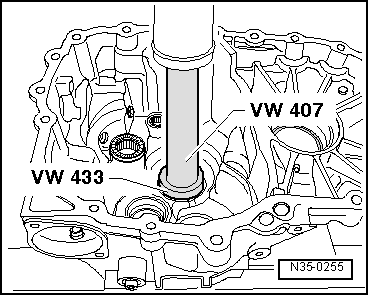

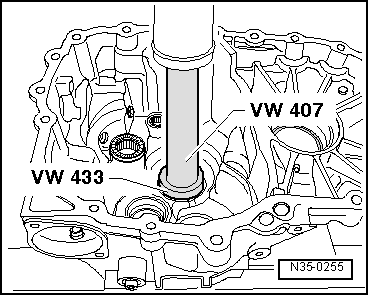

| t | Press tool -VW 407- |

| t | Thrust piece -VW 433- |

| t | Support bridge -30-211 A- |

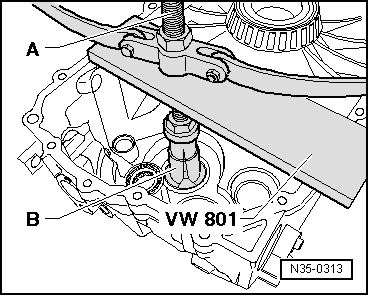

| t | Support plate -VW 801- |

| t | Support plate -VW 309- |

| t | Thrust piece -2050- |

| t | Torque wrench -V.A.G 1331- |

| t | -1-Internal puller -Kukko 21/7- |

| t | -4-Counterhold -Kukko 22/2- |

|

|

|

|

|

Note

Note

|

|

| Installed shim | 1.70 mm | |

| - | Measured value | 0.27 mm |

| + | Preload (constant) | 0.20 mm |

| Shim thickness | 1.63 mm |

|

|

|

| Thickness (mm) | ||

| 1.50 | 1.80 | 2.10 |

| 1.55 | 1.85 | 2.15 |

| 1.60 | 1.90 | 2,20 |

| 1.65 | 1.95 | 2.25 |

| 1.70 | 2.00 | |

| 1.75 | 2.05 |

|

|

|

|

|