Leon Mk1

| Secondary shaft for 5th/6th and reverse gear: dismantling and assembling |

| Check the tool and equipment equivalence table according to the applicability between Seat / VW / Audi / Skoda → Chapter. |

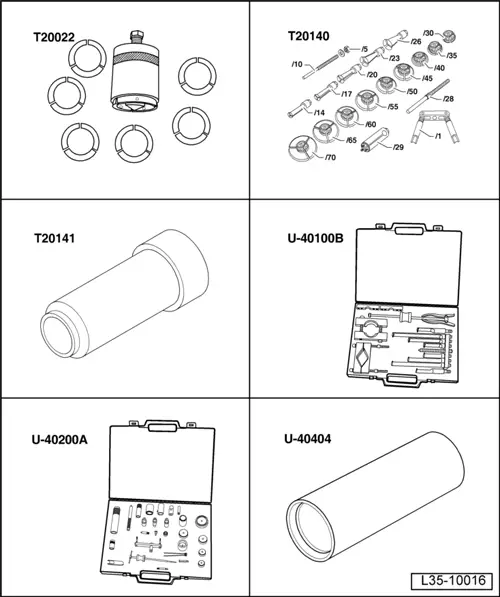

| Special tools and workshop equipment required |

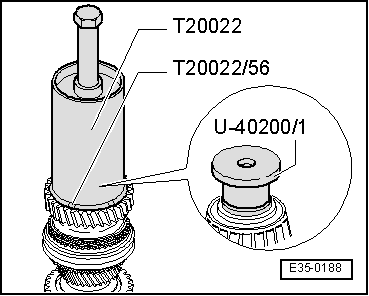

| t | Kit (case) -T20022-, see equivalent → Anchor |

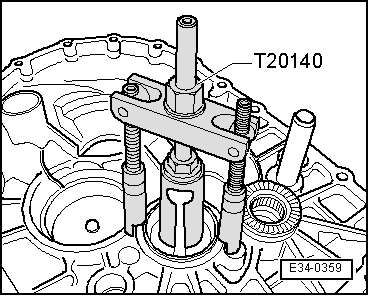

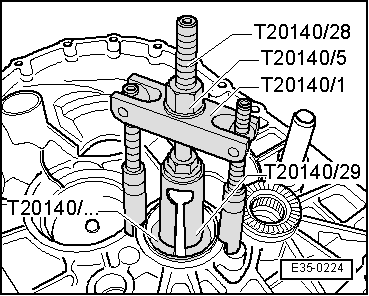

| t | Extractor kit -T20140-, see equivalent → Anchor |

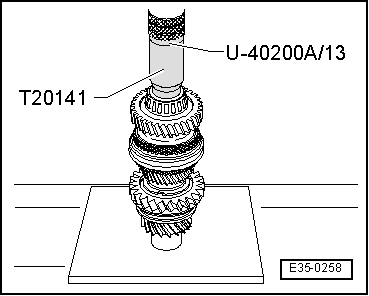

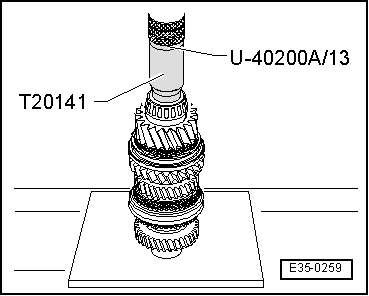

| t | Pressure tool -T20141-, see equivalent → Anchor |

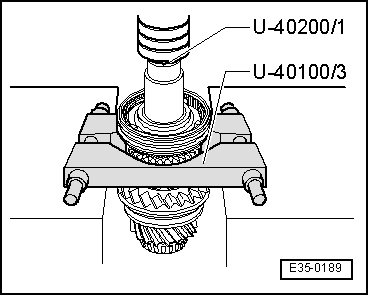

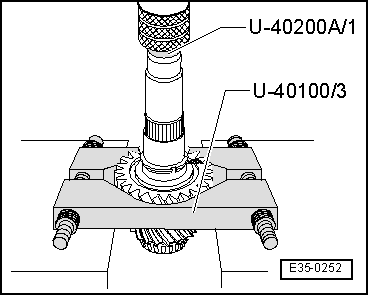

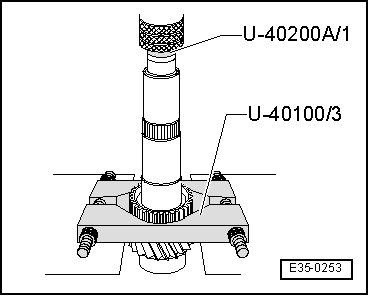

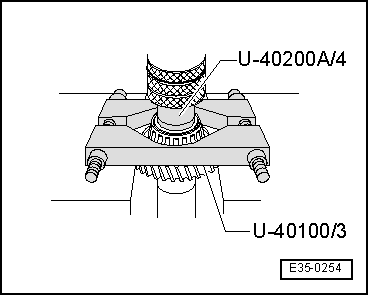

| t | Extractor kit -U 40100B-, see equivalent → Anchor |

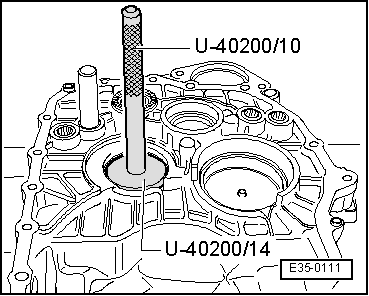

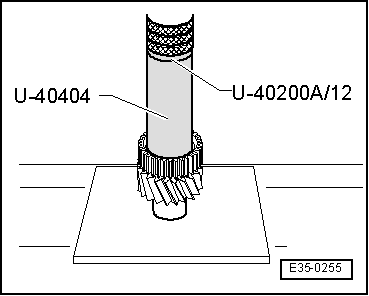

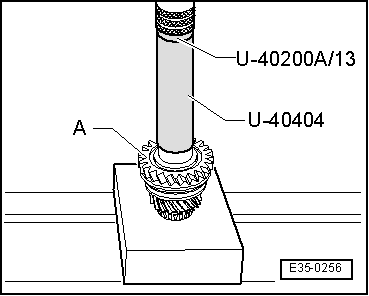

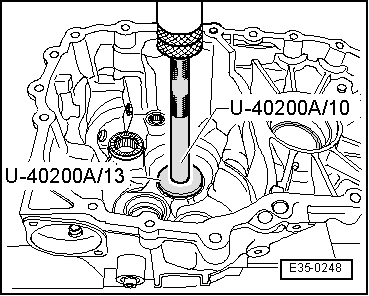

| t | Kit (case) -U 40200A-, see equivalent → Anchor |

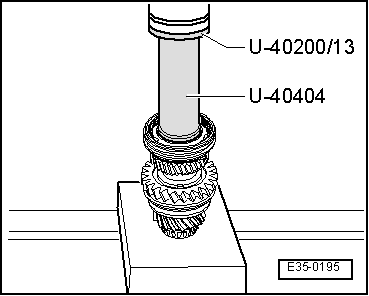

| t | Push rod -U-40404-, see equivalent → Anchor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

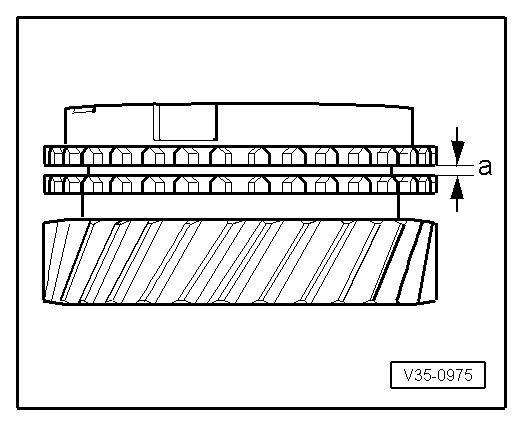

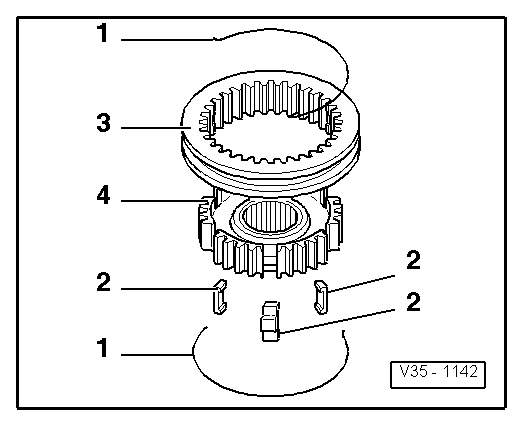

| Assembly level | Wear limit |

| 1.0 … 1.7 mm | 0.5 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note