Leon Mk1

|

|

|

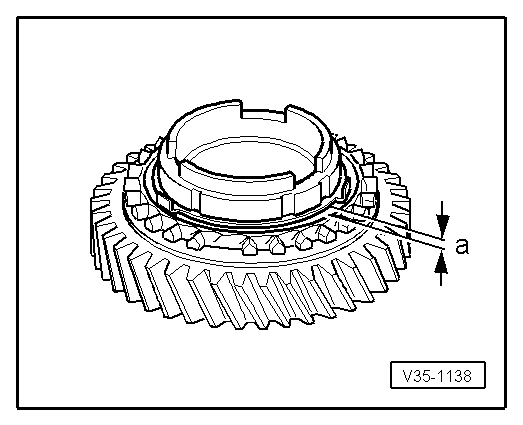

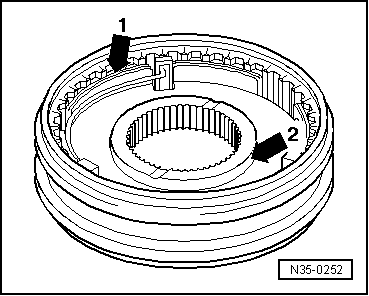

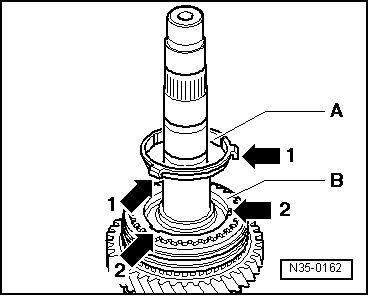

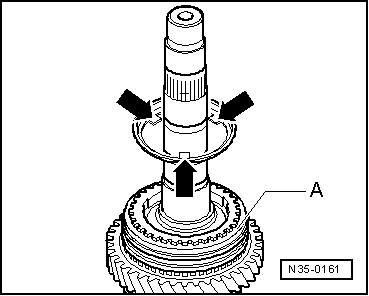

| Dimension -a- | Installation depth | Wear limit |

| 1., 2. 3rd gears | 0.75 ... 1.25 mm | 0.3 mm |

|

|

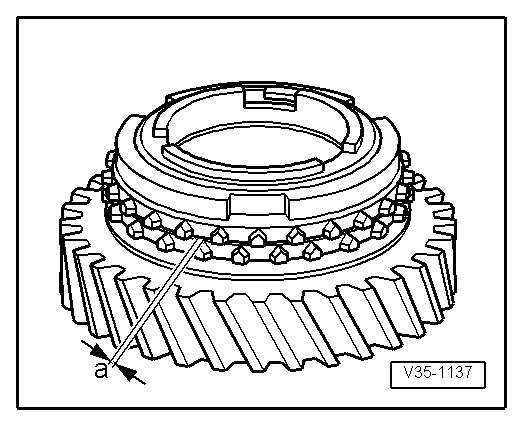

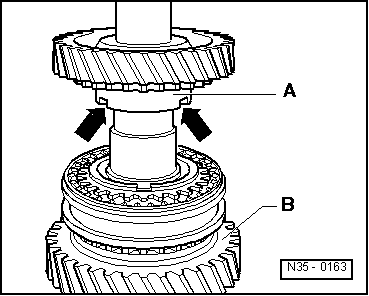

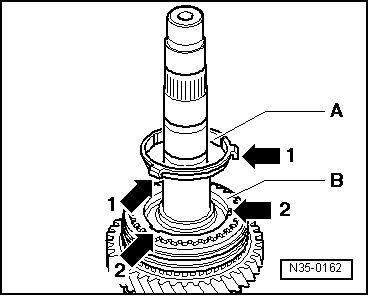

| Dimension -a- | Installation depth | Wear limit |

| 1., 2. 3rd gears | 1.2 ... 1.8 mm | 0.5 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

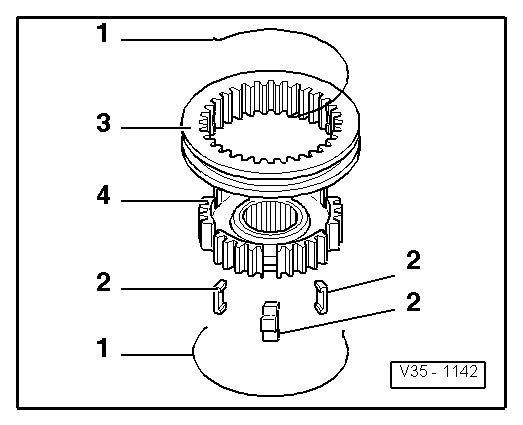

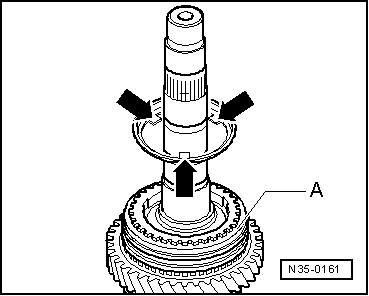

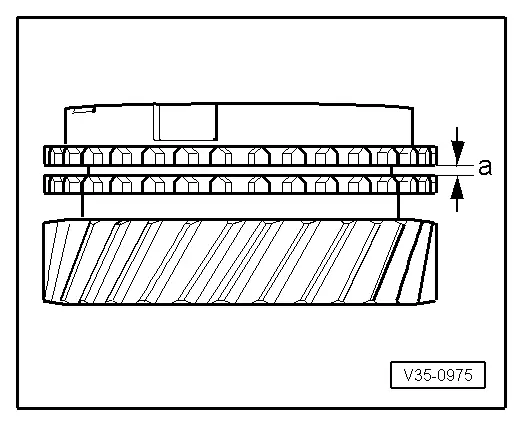

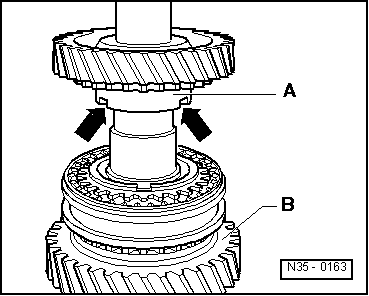

| Dimension -a- | Installation depth | Wear limit |

| 4. gear | 1.0 ... 1.7 mm | 0.5 mm |

|

|

|

|

|

|

|

|

Note

Note

|

|