Leon Mk1

|

|

|

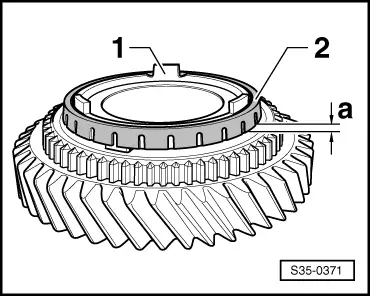

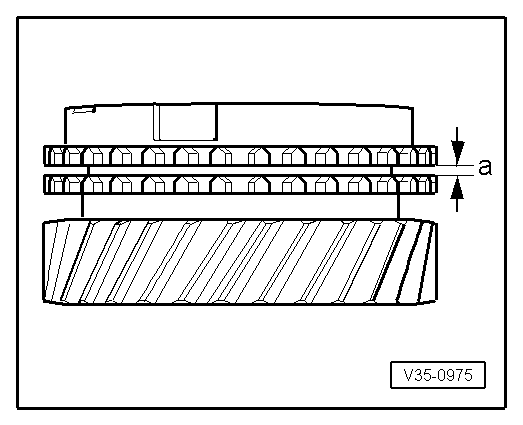

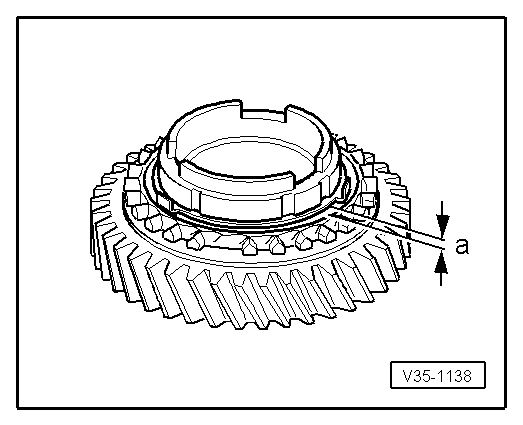

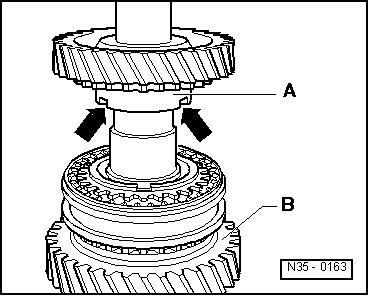

| Wear limit, dimension -a- | |

| 1. st gear and 2nd gear | 0.4 mm |

|

|

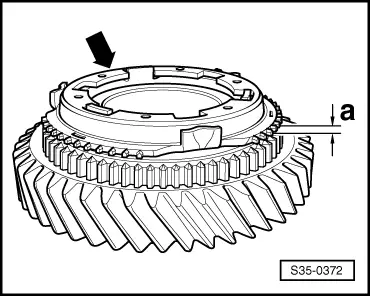

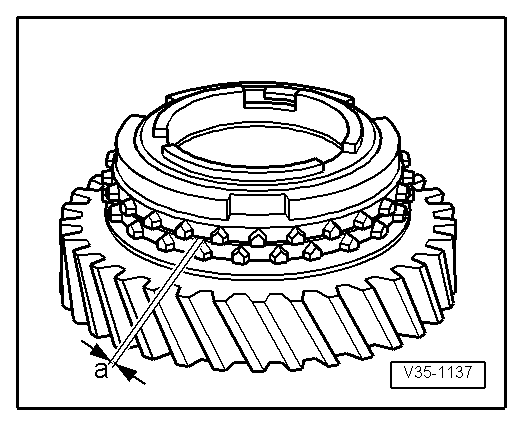

| Wear limit, dimension -a- | |

| 1. st gear and 2nd gear | 0.8 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

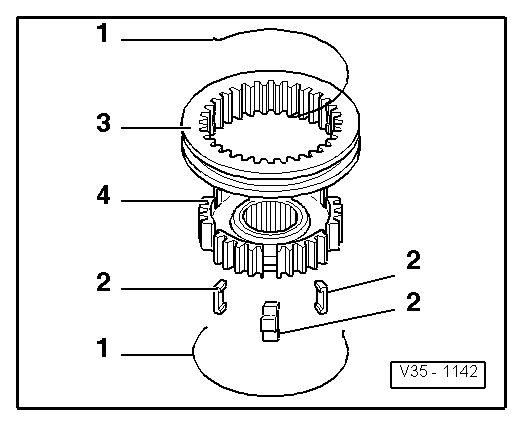

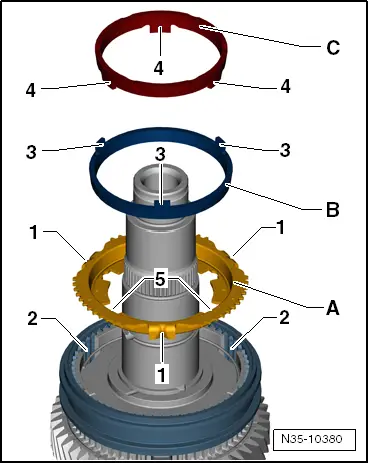

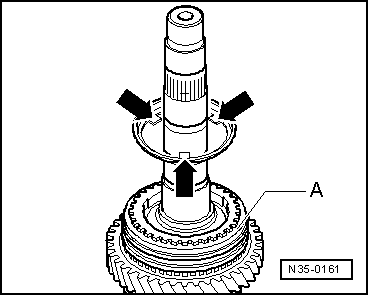

| Dimension -a- | Installation dimension | Wear limit |

| 4. gear | 1.0 ... 1.7 mm | 0.5 mm |

|

|

|

|

|

|

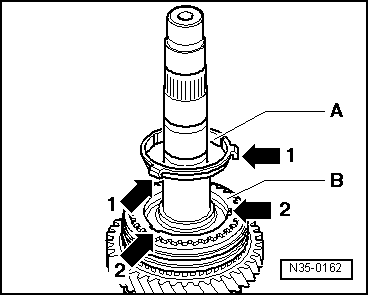

| Dimension -a- | Installation dimension | Wear limit |

| 3. gear | 0.75 ... 1.25 mm | 0.3 mm |

|

|

| Dimension -a- | Installation dimension | Wear limit |

| 3. gear | 1.2 ... 1.8 mm | 0.5 mm |

|

|

|

|

|

Note

Note

|

|