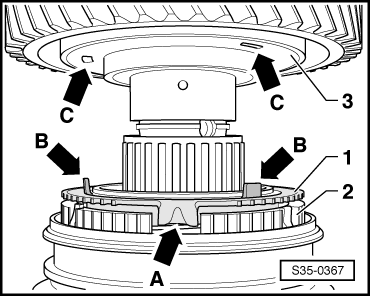

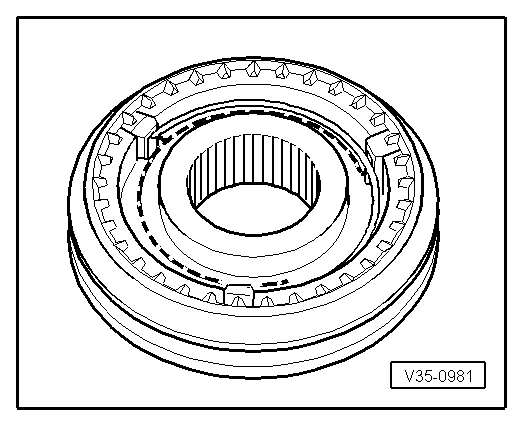

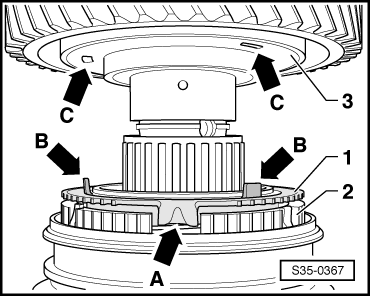

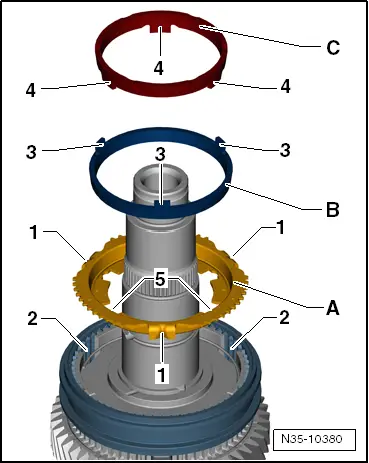

| Check the outer friction surface of the 1st, 2nd and 3rd gear for wear |

| –

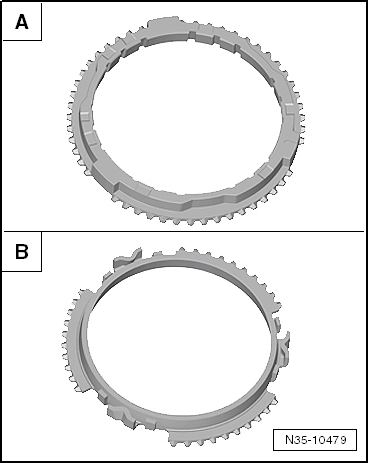

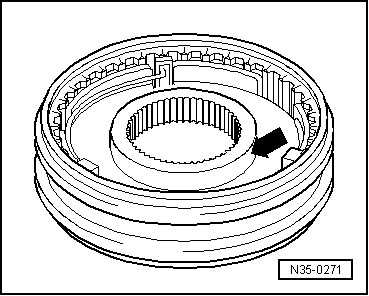

| Check the synchro ring -arrow- on the tyre on the inner friction surface or for an axial indication of wear, replace if necessary. |

| –

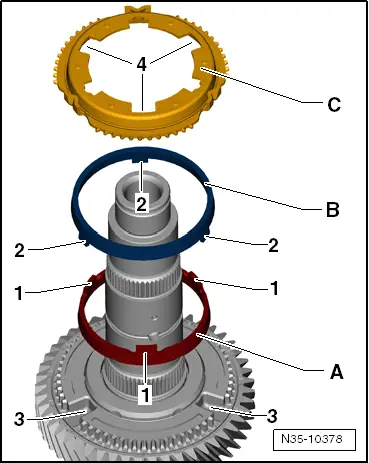

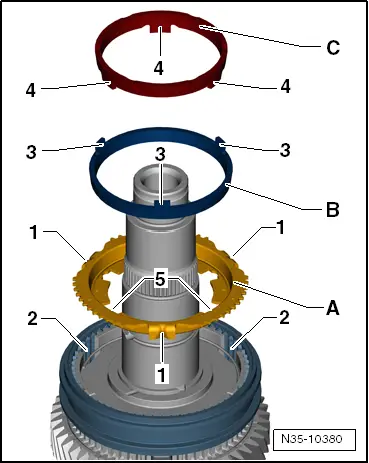

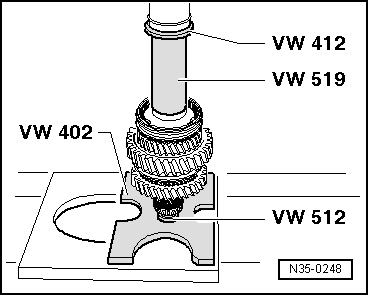

| Fit the inner ring, outer ring and the synchro-ring on the cone of the inner ring. |

| –

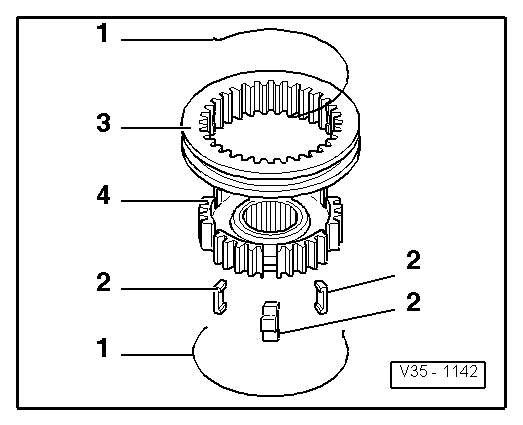

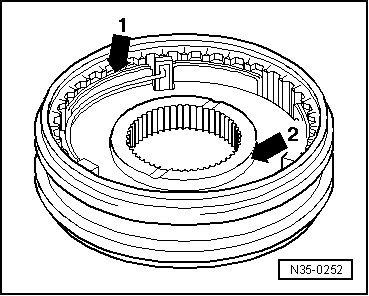

| Press the synchro-ring against the outer ring and turn them both to achieve the correct seating. |

| –

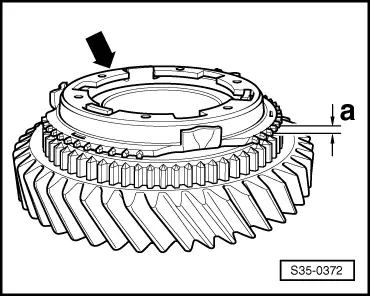

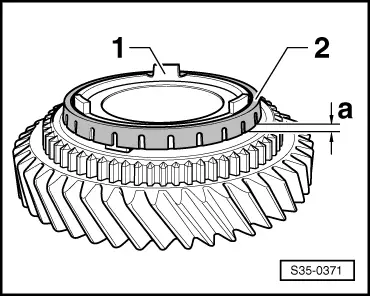

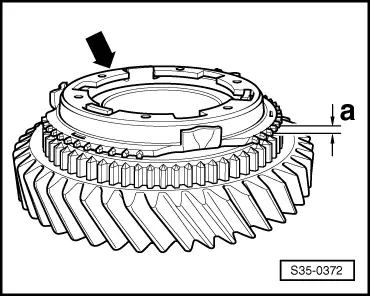

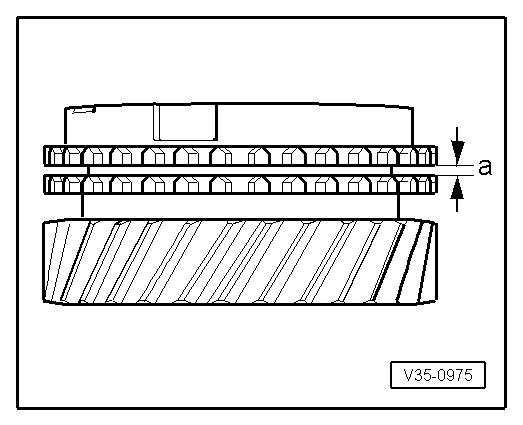

| Measure the clearance gap at 3 points -a- offset by approx. 120° using a feeler gauge. |

| –

| Make a note of average value. |

|

|

|

Note

Note