Leon Mk1

| Dismantling and assembling clutch housing |

| 1 - | clutch housing |

| q | Remove outer input shaft → Chapter |

| 2 - | Retainer washer |

| q | Smooth side faces outwards |

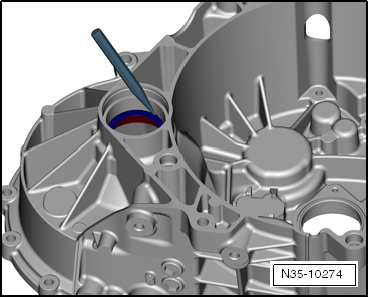

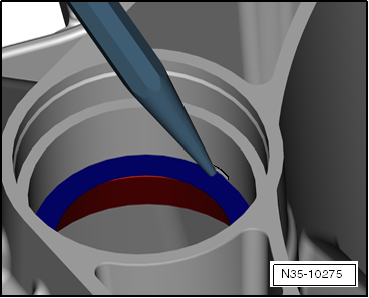

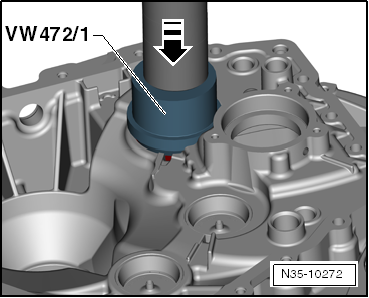

| 3 - | Differential bearing race |

| q | Pressing out → Fig. |

| q | Driving in → Fig. |

| 4 - | Output shaft shim 3 |

| q | Determining thickness → Chapter |

| 5 - | Oil deflector |

| q | Always renew a deformed plate |

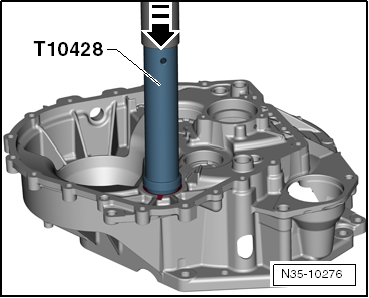

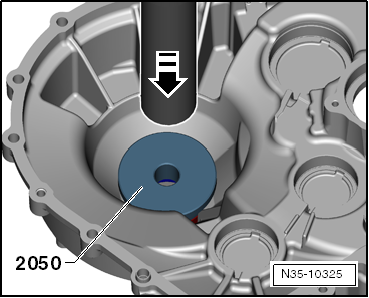

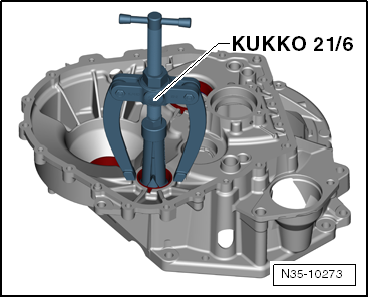

| 6 - | Output shaft bearing race 3 |

| q | Remove → Fig. |

| q | Preparing for pressing in → Fig. |

| q | Pressing in output shaft 3 → Fig. |

| 7 - | Output shaft shim 1 |

| q | Determining thickness → Chapter |

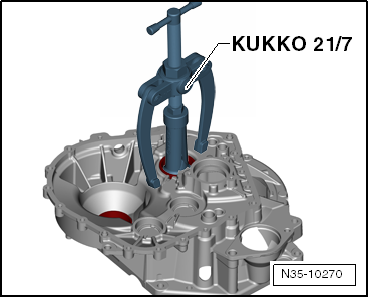

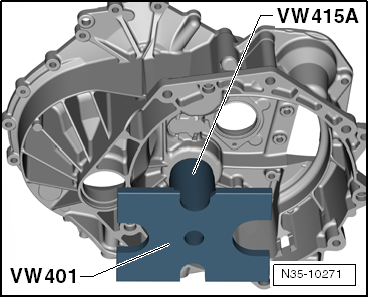

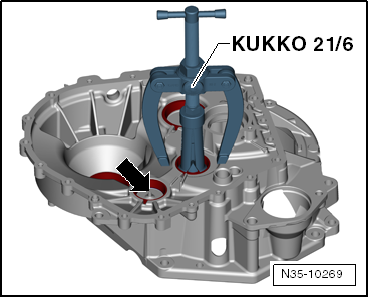

| 8 - | Output shaft bearing race 1 |

| q | Remove → Fig. |

| q | Preparing for pressing in → Fig. |

| q | Driving in → Fig. |

| 9 - | Output shaft shim 2 |

| q | Determining thickness → Chapter |

| 10 - | Output shaft bearing race 2 |

| q | Remove → Fig. |

| q | Preparing for pressing in → Fig. |

| q | Pressing in output shaft 2 → Fig. |

| 11 - | Outer input shaft |

| q | Removing → Chapter |

| q | Installing → Chapter |

| q | Dismantling and assembling → Chapter. |

| 12 - | Centring sleeve |

| q | 2 off |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|