Leon Mk1

|

|

|

Note

Note

|

|

| Installing |

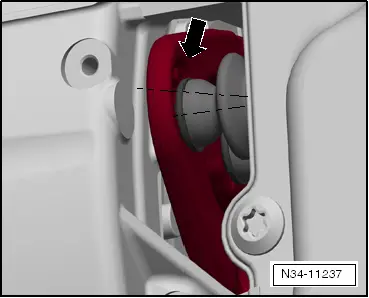

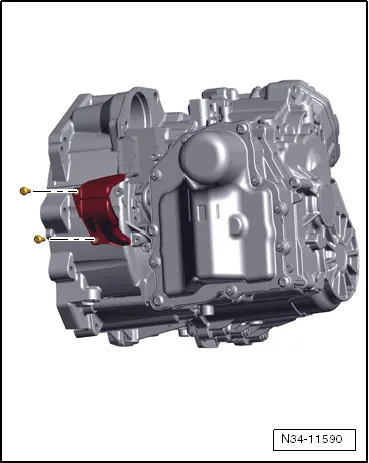

| – | Take care that all selector forks of the gearbox are put into »idling«. |

Note

Note| Make sure that all selector forks are located in -N-, »in the middle«, and therefore that the gearbox is in neutral. |

| – | Each of the 4 selector forks must be checked by hand for this purpose. |

| Each selector fork has 3 possible positions: »Gear engaged - Neutral position - Gear engaged«. |

| – | Each switching fork must be put into every position one after another. Then all gears must be pulled out and the switching forks must be moved to the »centre position«. |

Note

Note| »Neutral, neutral, neutral«, or gearbox will not function! |

| You can turn the gear slightly for assistance. This makes it »easier« to shift the forks. |

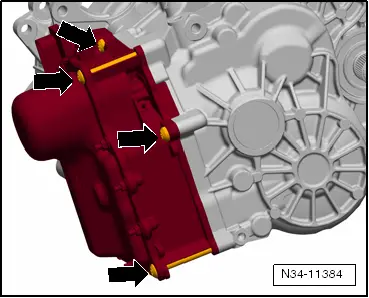

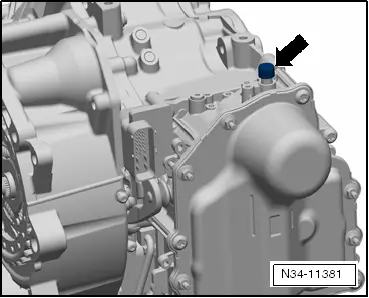

| – | Clean the sealing surface to which the mechatronic will be fitted later. |

| Oil residues on sealing surface will later result in a misdiagnosis of »leaking«. |

|

|

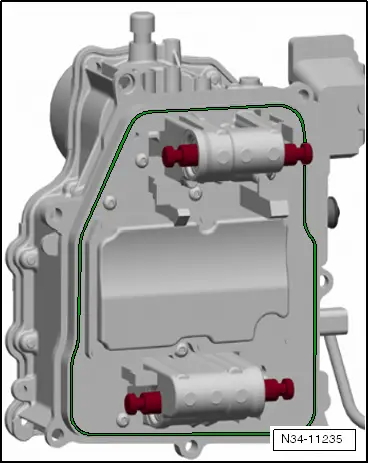

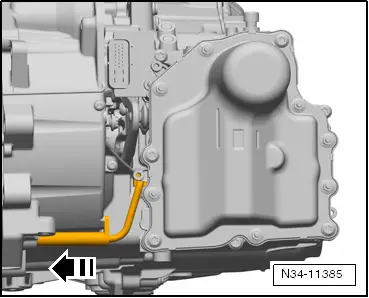

| Make sure that all gear actuators project by 25 millimetres -a-. |

Caution

Caution

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|