Leon Mk1

| Gearbox : removing and fitting |

| Consult the equivalence table for tools and equipment according to applicability among Seat / VW / Audi / Skoda → Chapter. |

| Special tools and workshop equipment required |

| t | Kit (case) -T20017A -, see equivalent → Anchor |

| t | Base -T20029 -, see equivalent → Anchor |

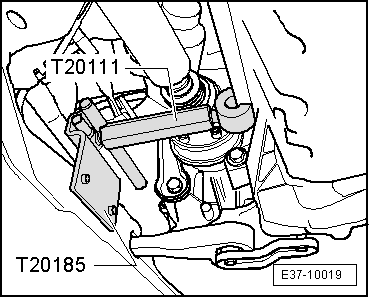

| t | counterhold -T20111 -, see equivalent → Anchor |

| t | counterhold -T20185 -, see equivalent → Anchor |

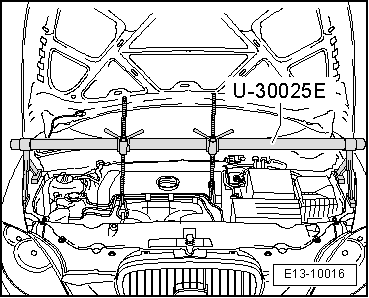

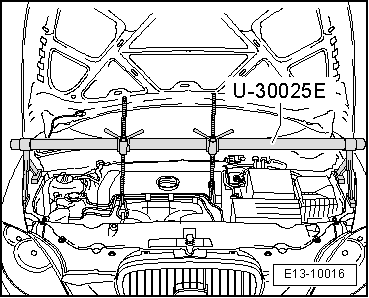

| t | Socket -U-30025E -, see equivalent → Anchor |

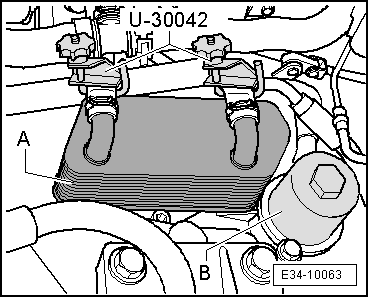

| t | Hose clamp -U-30042 -, see equivalent → Anchor |

| t | Hydraulic jack -SAT 1040-, see equivalent → Anchor |

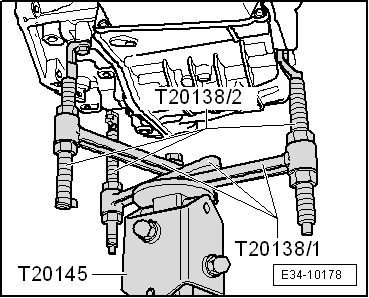

| t | counterhold -T20138C -, see equivalent → Anchor |

| t | base -T20145 -, see equivalent → Anchor |

| t | Adapter for the hydraulic engine and gearbox jack -SAT 1001/1- |

Note

Note

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING

WARNING