| t

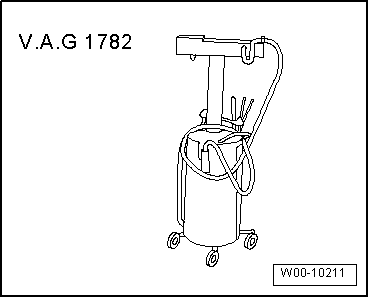

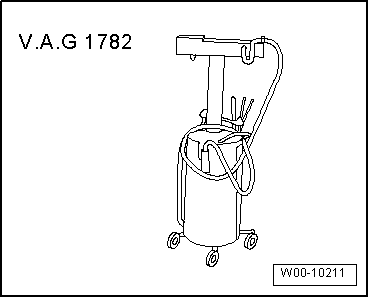

| Used oil collection and extraction unit -V.A.G 1782- |

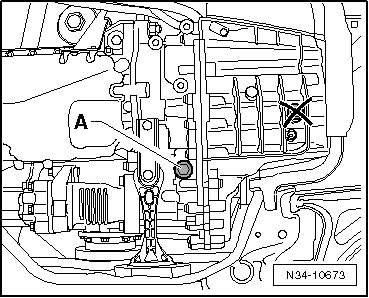

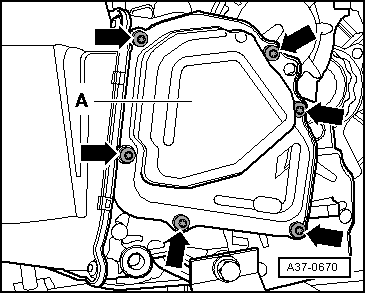

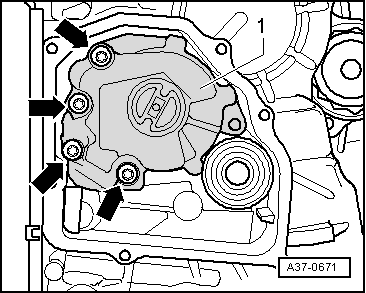

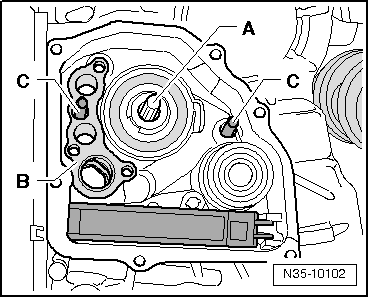

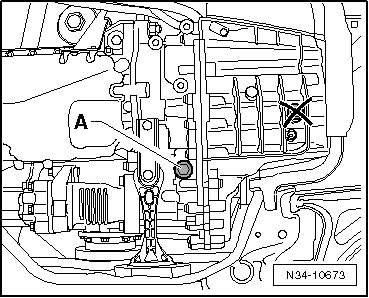

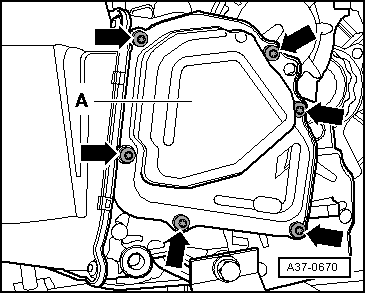

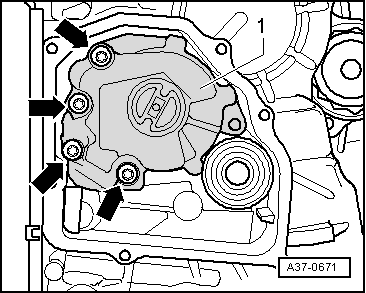

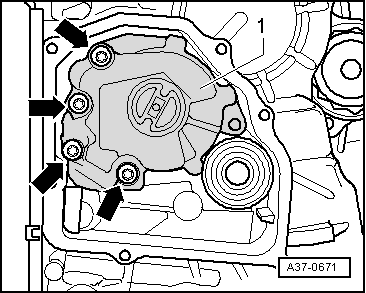

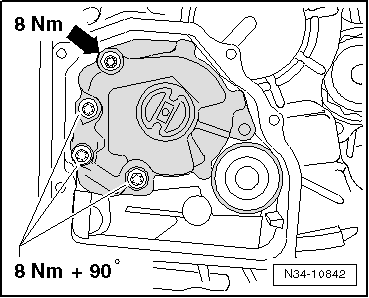

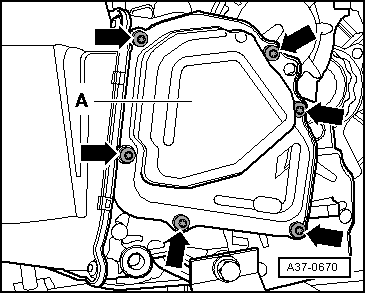

| The oil pump can be renewed without the gearbox being removed. The vehicle must be raised and any covers present beneath the front part of the vehicle must be removed. The connection between suspension link and suspension strut does not need to be separated. The drive shaft does not need to be removed. Do not „carry out basic adjustment“ either. Only the → DSG® oil and pump cover must be renewed. |

| –

| Position used oil collection and extraction unit -V.A.G 1782- under gearbox. |

| Please also refer to the notes on the oil filter change regarding »dirty oil« → Chapter. |

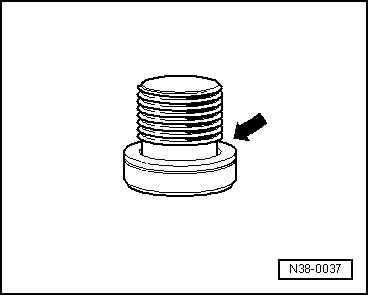

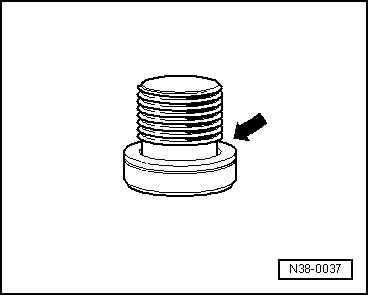

| To gearbox manufacture date „20 September 2004“, gearboxes were constructed with 2 plugs. |

|

|

|