Leon Mk1

|

Adjusting front final drive -Overview-

Adjusting differential

|

|

|

|

|

|

|

|

|

Conditions: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

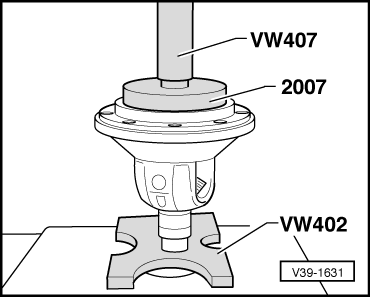

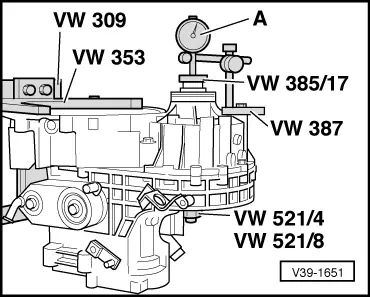

When performing measurement, do not turn differential otherwise the bearings will settle and the result of the measurement will be falsified. Determining shim The specified bearing preload is achieved if the bearing preload of 0.12 mm and the settling amount of 0.10 mm is added to the figure obtained from the measurement. Example:

| ||||||||||||

|

|

|