Leon Mk1

|

Removing and installing propshaft

Removing and installing propshaft

|

|

|

|

A twin pillar lifting platform should be used when working on the propshaft.

|

|

|

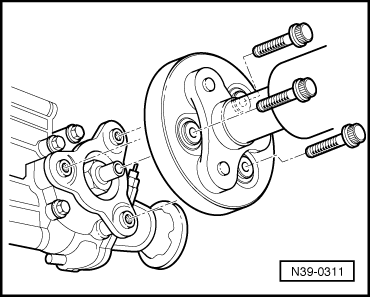

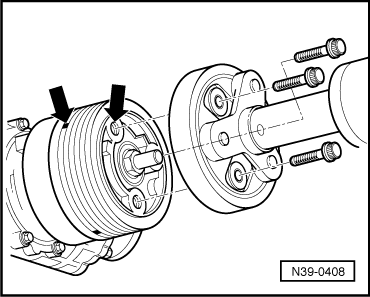

Removing front propshaft Removing rear propshaft => Page 39-91 Removing front propshaft |

|

|

|

|

|

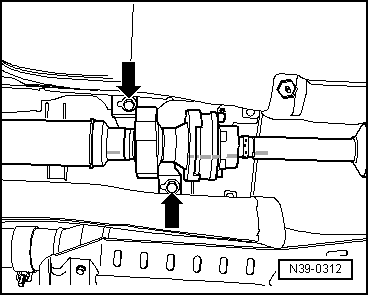

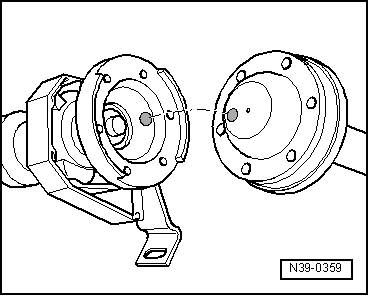

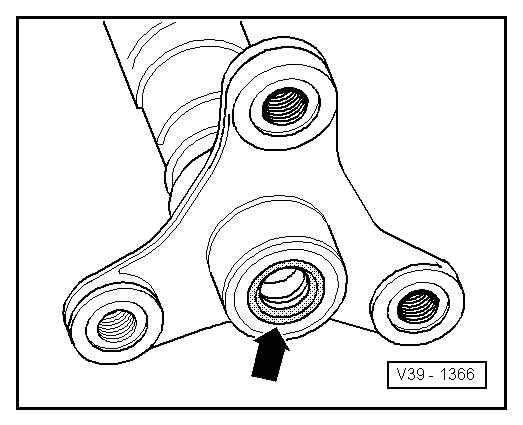

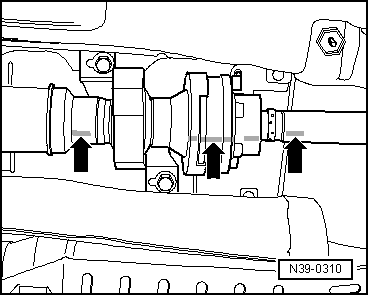

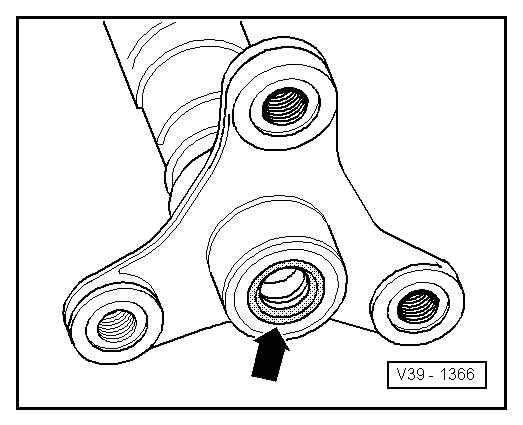

The three marks in the grooves align with the threaded holes for securing the propshaft (arrows).

Secure front propshaft against falling if only rear propshaft is to be removed. |

|

|

|

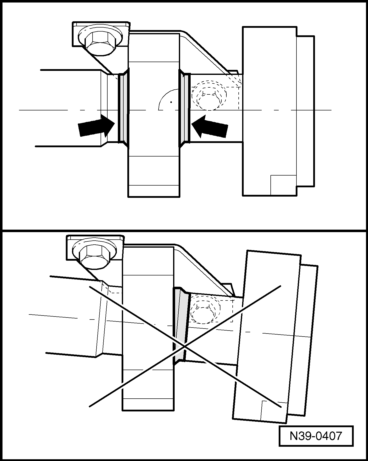

Installing Installation of the propshaft is carried out in the reverse sequence.

|