Leon Mk1

|

Dismantling and assembling rear final drive

Dismantling and assembling sequence

|

|

|

|

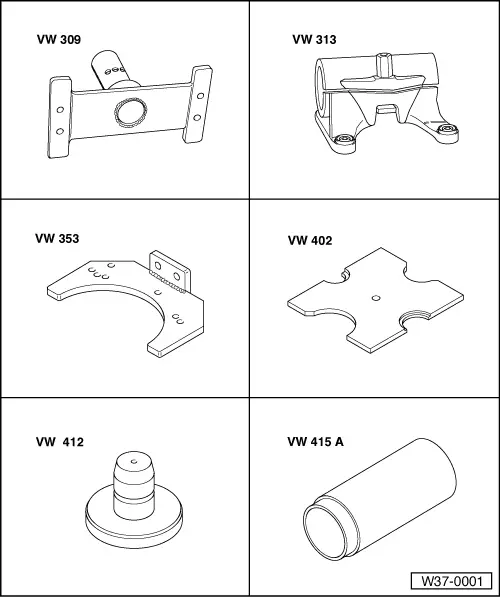

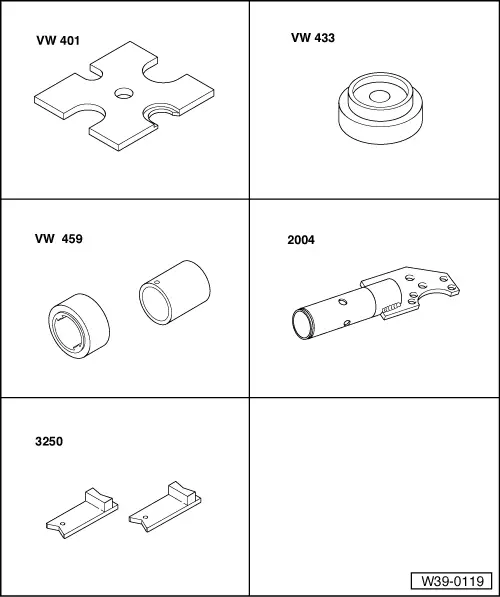

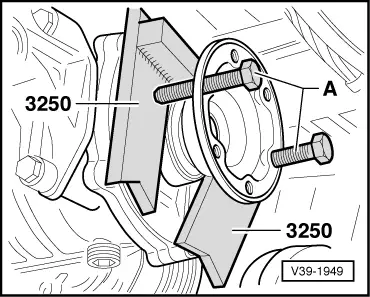

Special tools and workshop equipment required

|

|

|

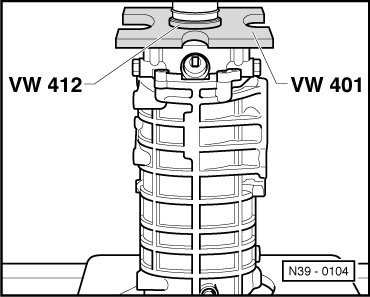

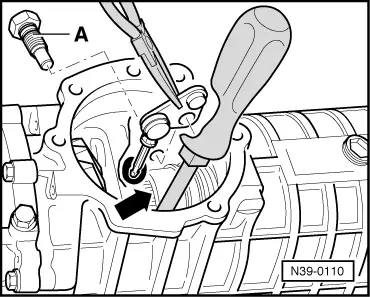

Dismantling and assembling viscous coupling, pinion housing/shaft bevel gear, input shaft bevel gear, differential, differential lock and freewheel Dismantling

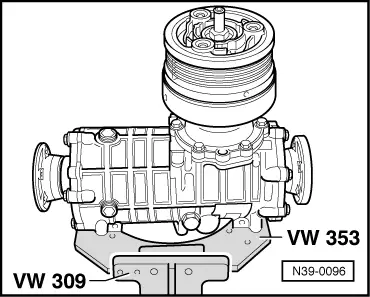

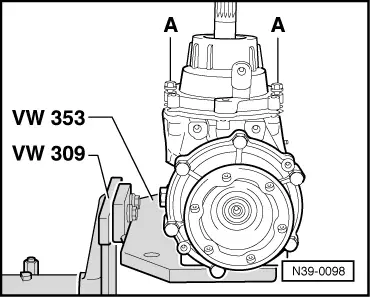

Rear final drive with freewheel

|

|

|

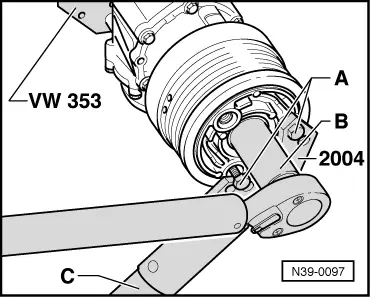

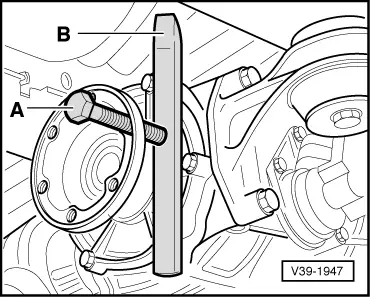

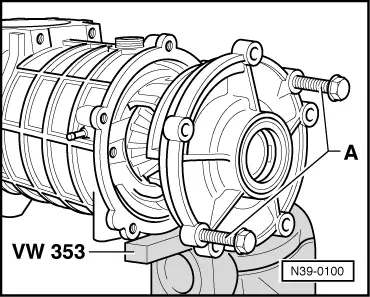

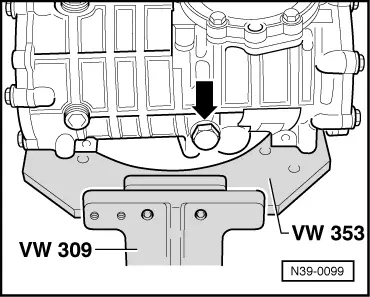

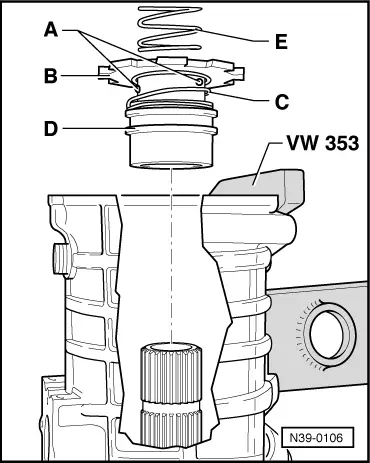

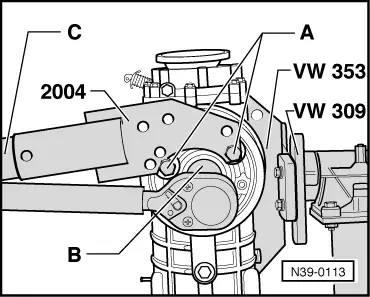

To secure the final drive to assembly bracket a new hole is required in gearbox holder VW 353. Modifying gearbox holder VW 353 . |

|

|

|

|

|

|

|

|

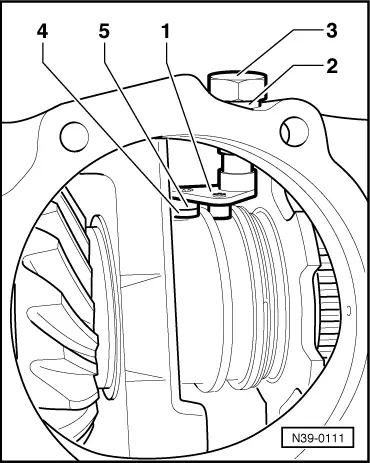

Rear final drive with freewheel

|

|

|

|

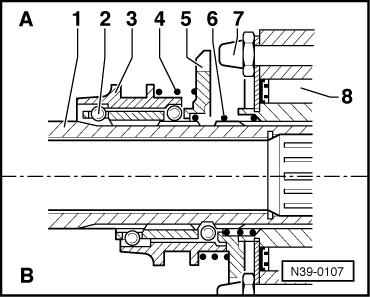

Rear final drive with freewheel

|

|

|

|

The removal is identical to removing the right-hand cover => Page 39-144.

Assembling

|

|

|

|

|

|

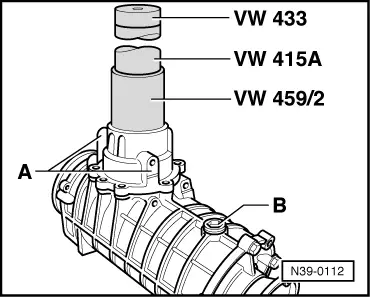

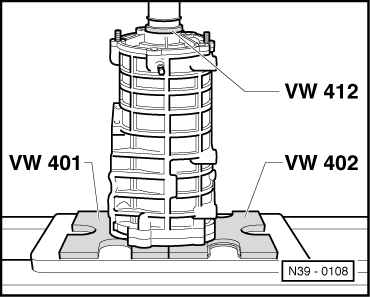

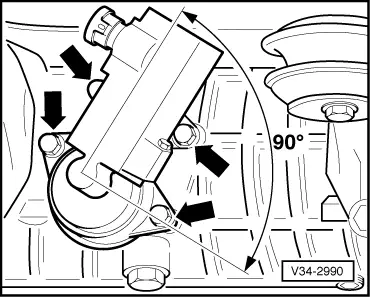

Rear final drive with freewheel

|

|

|

|

|

|

|

|

|

|

Rear final drive with freewheel

|

|

|

|

|

|

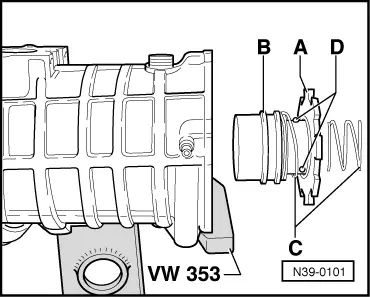

When tightening viscous coupling centralizing nut counter-hold using pipe -C- with special tool 2004 (2nd mechanic).

|

|

|

|

Rear final drive with freewheel |