Leon Mk1

|

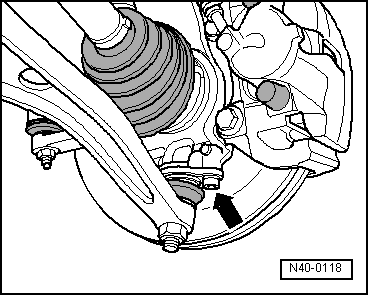

Removing and installing front left flange shaft

Removing and installing front left flange shaft

|

|

|

|

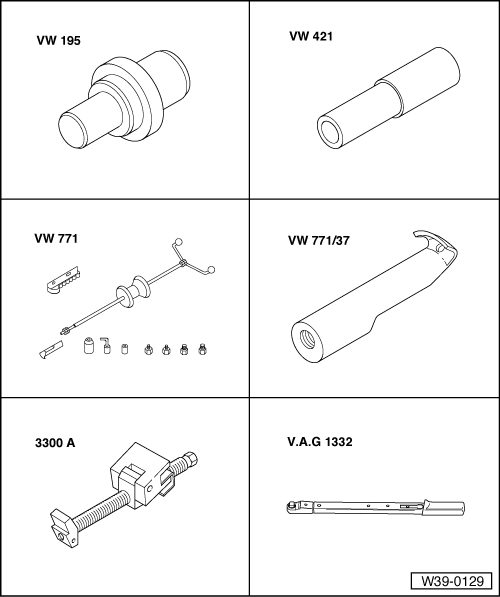

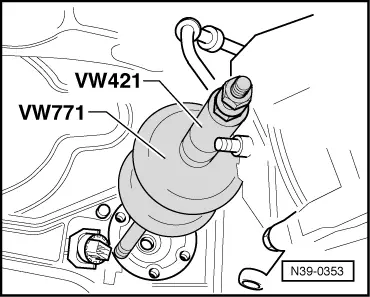

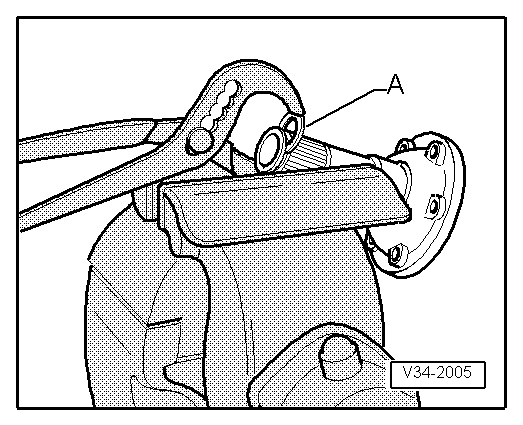

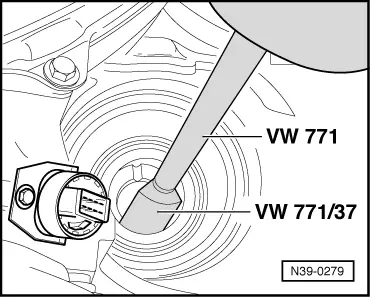

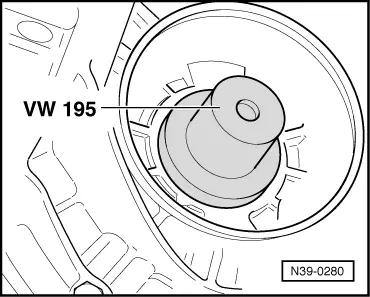

Special tools and workshop equipment required

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

Tightening torques:

|