Leon Mk1

|

Removing and installing front right flange shaft and bevel gear input shaft oil seals

Removing and installing front right flange shaft and bevel gear input shaft oil seals

|

|

|

|

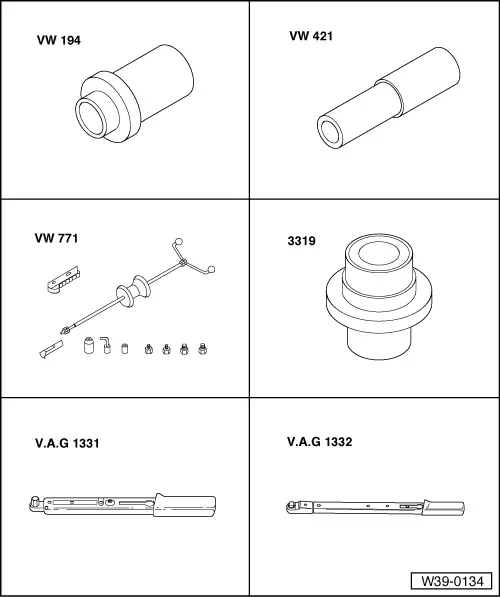

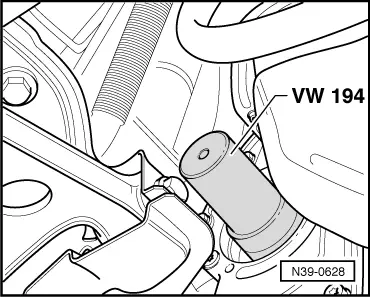

Special tools and workshop equipment required

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

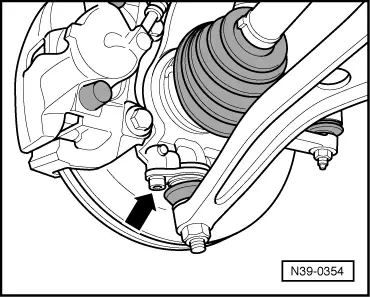

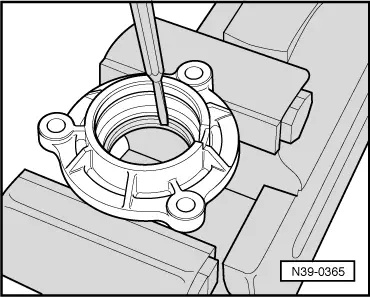

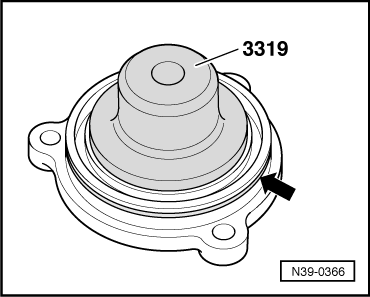

Installation position of seal:

|

|

|

|

||||||||||||

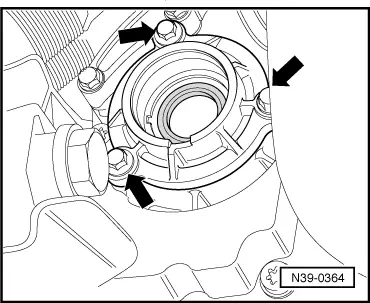

Tightening torques:

|