Leon Mk1

|

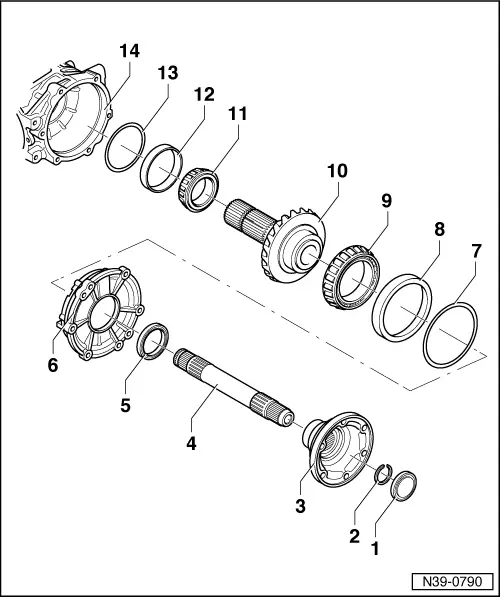

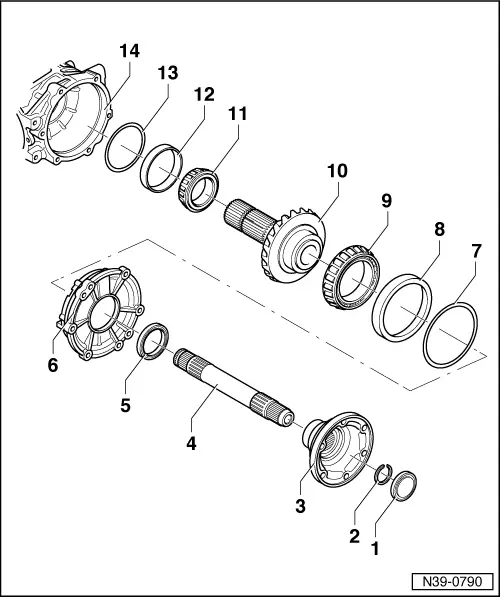

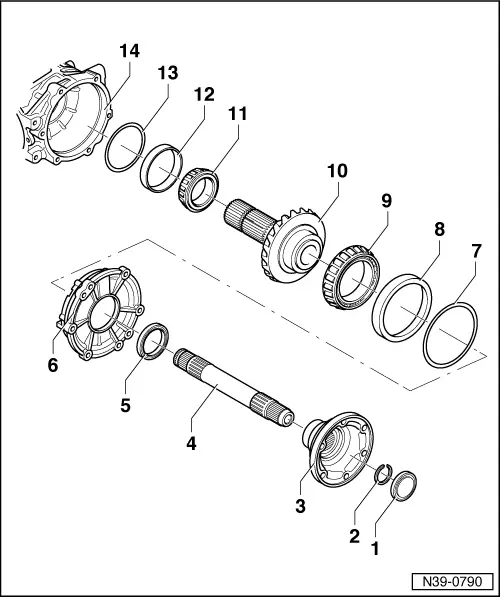

Servicing input shaft bevel gear bearings

Assembly overview

Dismantling and assembling sequence 1) Adjustment work is required if these components are replaced => Adjustment overview Page 39-193. |

|

|

|

|

|

=> Replacement parts catalogue |

|

|