Leon Mk1

| Dismantling and assembling 1st to 3rd gear clutch -K1- |

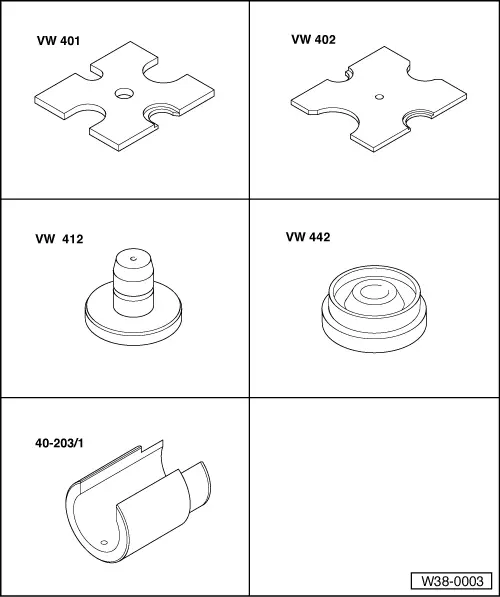

| Special tools and workshop equipment required |

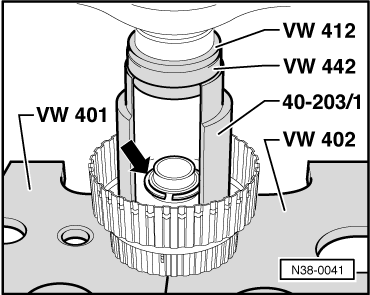

| t | Pressure plate -VW 401- |

| t | Pressure plate -VW 402- |

| t | Press tool -VW 412- |

| t | Pressure piece -VW 442- |

| t | Tube -40 - 203/1- |

| The clutch is only allowed to be dismantled for cleaning or when you are carrying out visual check. |

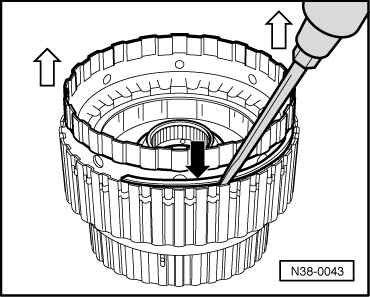

| Clutches -K1- and -K3- can be pressed together in some gearboxes. |

| Pressing -K1- off -K3- → Chapter. |

| Pressing -K1- onto -K3- → Chapter |

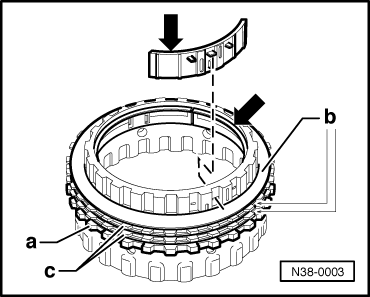

| 1 - | Supporting ring |

| q | Unclipping from inner disc carrier in 4 pieces. |

| q | Installing → Fig.. |

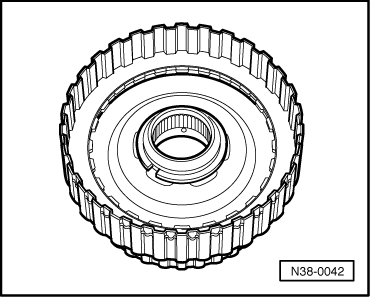

| 2 - | Inner disc carrier |

| q | Installing → Fig.. |

| q | Assembling → Fig.. |

| 3 - | Circlip |

| q | Different thickness. |

| q | Marking after removing and inserting at same point. |

| 4 - | Pressure plate |

| q | Smooth side faces inner disc. |

| q | Inserting together with inner disc carrier → Fig.. |

| 5 - | Inner disc |

| q | Quantity → Chapter. |

| q | Installing → Fig.. |

| q | Before installing place in ATF for 15 minutes. |

| 6 - | Outer disc |

| q | Quantity → Chapter. |

| q | Installing → Fig.. |

| q | Always 1.5 mm thick. |

| 7 - | Outer disc |

| q | Always 2.0 mm thick. |

| q | Installing → Fig.. |

| 8 - | Corrugated washer |

| 9 - | Circlip |

| q | Removing and installing → Fig.. |

| 10 - | Piston cap |

| q | Sealing lips are vulcanised to cap. |

| q | Moistening sealing lips with ATF before installing. |

| q | Turn cap slightly when installing. |

| 11 - | Intermediate spring ring |

| q | With spring supporting shell and compression springs. |

| 12 - | Piston |

| q | Sealing lips are vulcanised to piston. |

| q | Moistening sealing lips with ATF before installing. |

| q | Turning piston slightly when installing. |

| 13 - | Clutch housing |

| q | Before inserting the inner disc carrier, place corrugated washer → Item, inner and outer discs into the clutch housing → Fig.. |

|

|

|

|

|

|

|

|