Leon Mk1

| Dismantling and assembling reverse gear clutch -K2- |

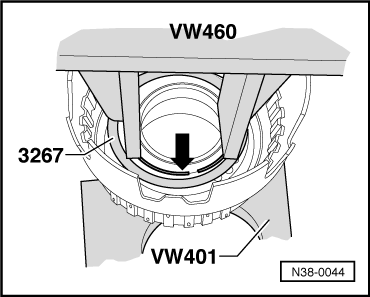

| Special tools and workshop equipment required |

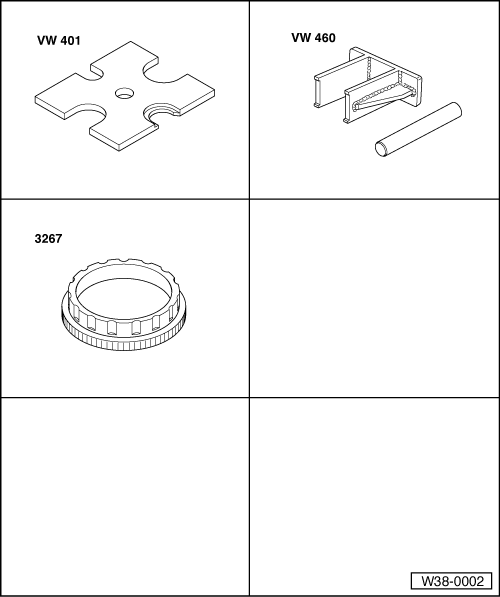

| t | Pressure plate -VW 401- |

| t | Removing tool -VW 460- |

| t | Assembly ring -3267- |

| The clutch is only allowed to be dismantled for cleaning or when you are carrying out visual check. |

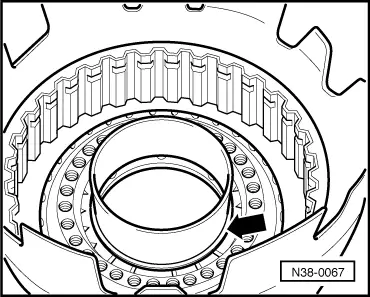

| When doing this ensure that the ball valve -arrow- is not damaged. |

| 1 - | Circlip |

| q | Marking after removing and inserting at same point. |

| 2 - | Pressure plate |

| q | Smooth side facing inner discs. |

| 3 - | Inner disc |

| q | Quantity → Chapter. |

| 4 - | Outer disc |

| q | Quantity → Chapter. |

| 5 - | Corrugated washer |

| 6 - | Circlip |

| q | Removing and installing → Fig.. |

| q | Installation position → Fig.. |

| 7 - | Spring supporting plate |

| q | With springs. |

| q | Installation position → Fig.. |

| 8 - | Spring supporting ring |

| 9 - | Piston |

| q | Sealing lips are vulcanised to piston. |

| q | Moistening sealing lips with ATF before installing. |

| q | Turning piston slightly when installing. |

| 10 - | Clutch housing |

|

|