Leon Mk1

|

Removing and installing cylinder head

Removing, installing and tensioning toothed belt

|

|

|

|

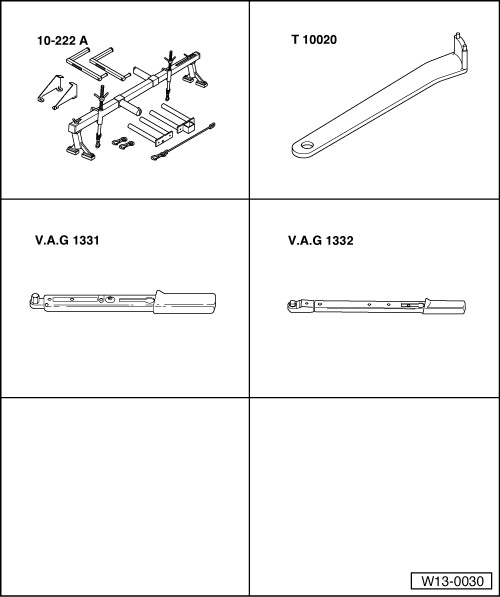

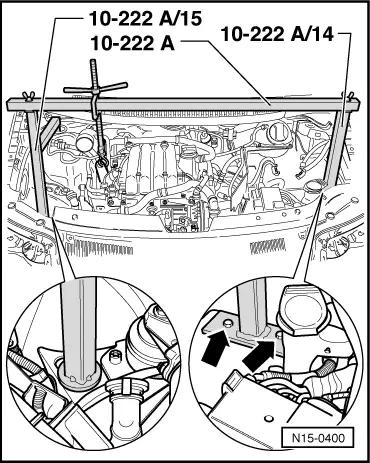

(Adjusting valve timing) Special tools, workshop equipment, test and measuring appliances and auxiliary items required

Removing

=> Repair group 24; Servicing injection system; Dismantling and assembling air cleaner. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

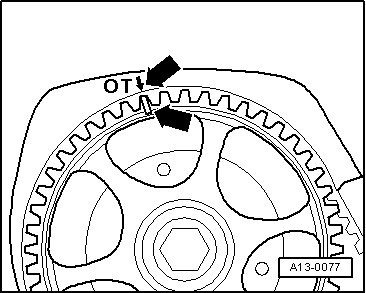

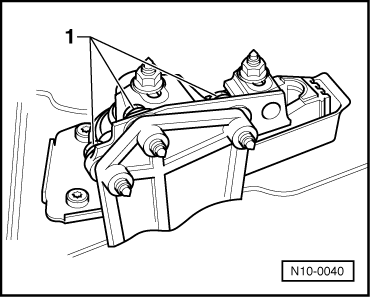

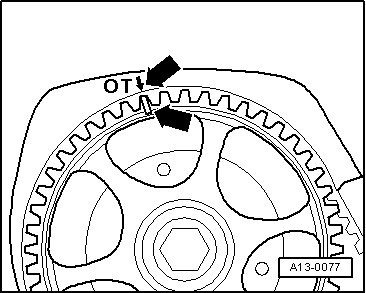

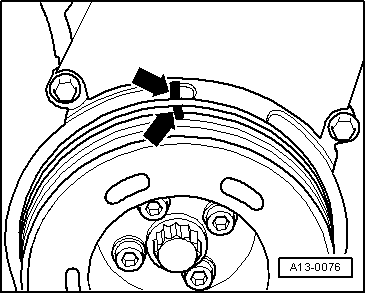

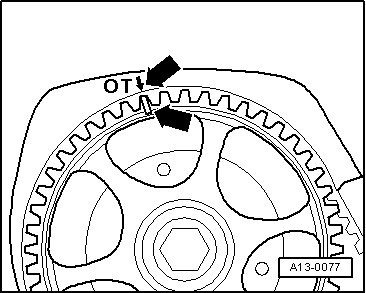

Installing Note: When the camshaft is turned, the crankshaft must not be at TDC. Danger of damage to valves or piston crowns. A - Toothed belt completely removed If toothed belt has only been removed from camshaft => Page 15-11 Conditions

Work sequence |

|

|

|

|

B - Toothed belt only taken off camshaft sprocket |

|

|

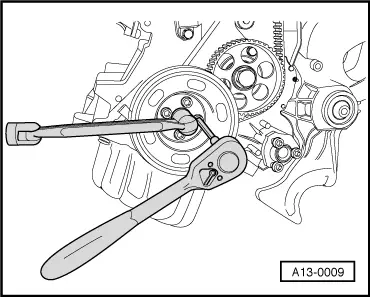

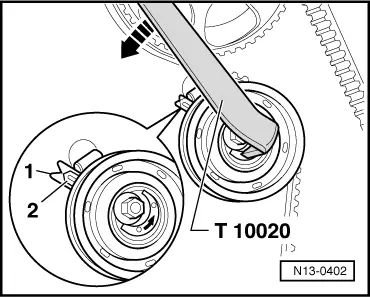

Tensioning toothed belt Conditions

Work sequence |

|

|

Continuation, installing toothed belt

=> Repair group 24; Servicing injection system; Dismantling and assembling air cleaner.

|