Leon Mk1

|

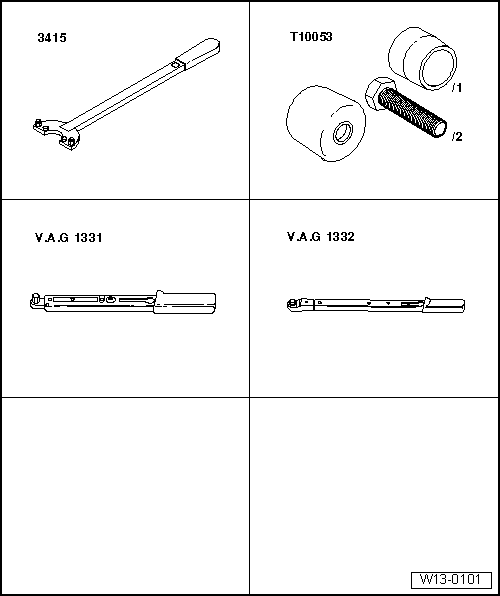

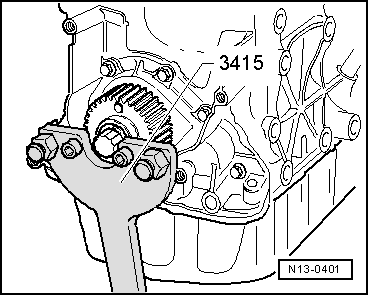

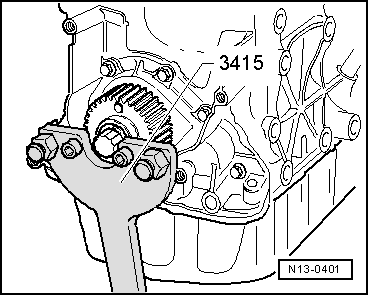

Removing and installing sealing flange and pressure plate/drive plate

Removing and installing front sealing flange

|

|

|

|

|

|

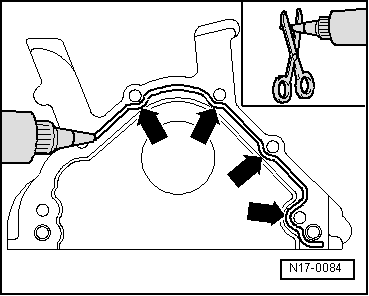

Installing Notes:

|

|

|

Notes:

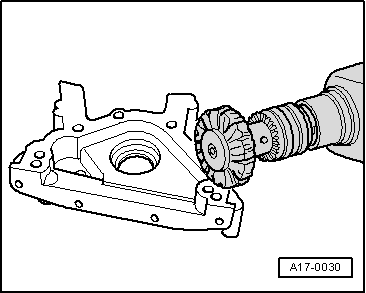

Note: Use guide sleeve T10053/1 to fit sealing flange with the oil seal already installed.

Note: After installing, the sealant must be allowed to dry for approx. 30 minutes before engine oil is replenished. |

|

|

Note: Thread and shoulder must be free of oil and grease. Installing toothed belt and adjusting valve timing => Page 15-6.

|