Leon Mk1

|

Removing and installing sealing flange and pressure plate/drive plate

Renewing crankshaft oil seal -belt pulley end

|

|

|

|

|

|

|

|

|

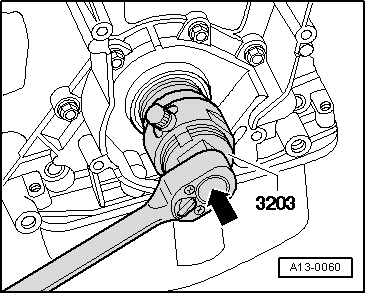

Installing Note: Gradual introduction of PTFE oil seals (Poly-Tetra-Fluor-Ethylen). Identifying characteristics: no annular spring, sealing lip wider. The sealing lip of this oil ring must not be oiled or lubricated. A plain encased seal of older construction (with annular spring) may be replaced with a PTFE oil seal, but not vice versa. |

|

|

|

|

|

|

|

|

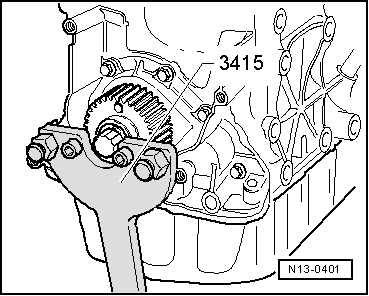

Note: Thread and shoulder must be free of oil and grease. Installing toothed belt and adjusting valve timing => Page 15-6.

|