|

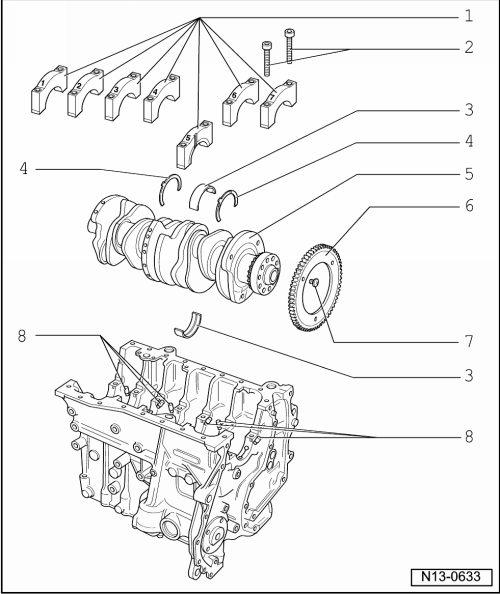

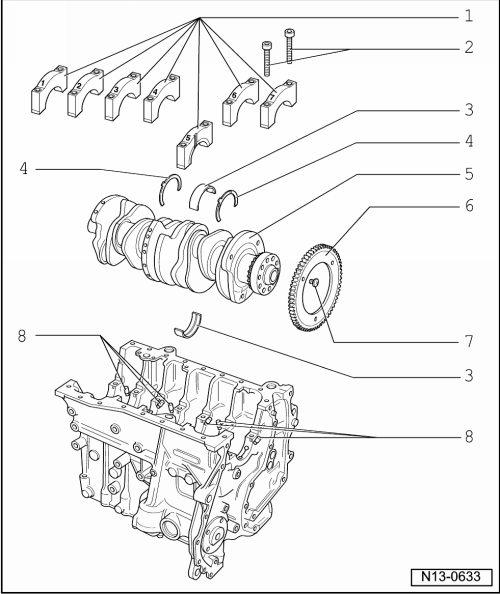

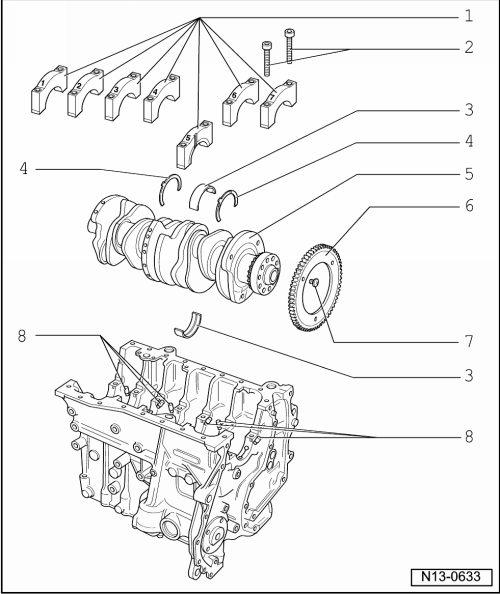

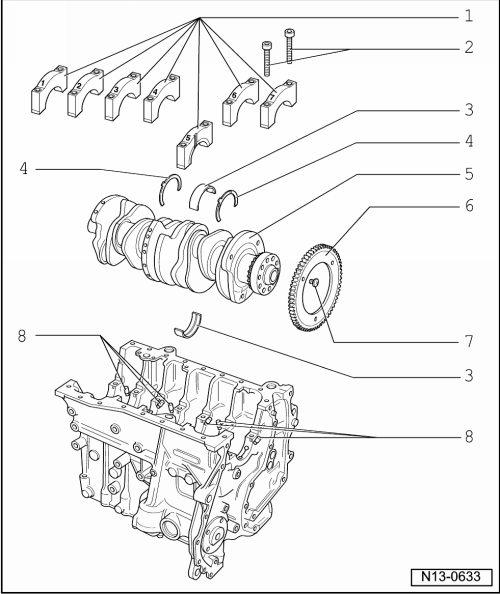

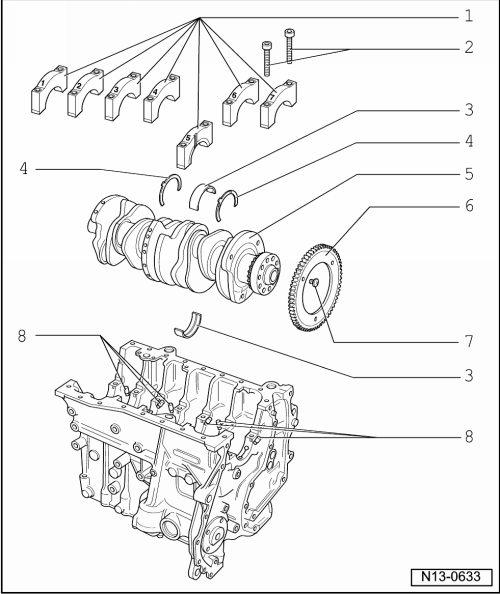

→ Fig.1 Fitting sender wheel to crankshaft

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

-

◆ V.A.G 1331 Torque wrench (5...50 Nm)

-

◆ D 000 600 A2 Locking fluid

Ensure crankshaft/sender wheel contact surfaces are free of oil and grease.

-

‒ Apply a thin coat of locking fluid D 000 600 A2 to contact surfaces between crankshaft and sender wheel for additional hold.

-

‒ First hand tighten all new securing bolts.

-

‒ First tighten securing bolt -1- to

10 Nm + 90° (1/4 turn).

-

‒ Then tighten securing bolts -2- to

10 Nm + 90° (1/4 turn).

|