Leon Mk1

|

Removing and installing sealing flanges and two-part flywheel

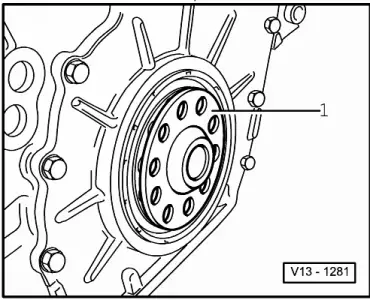

Removing and installing drive plate

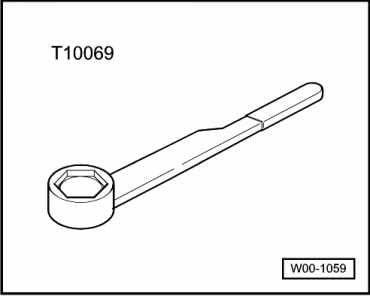

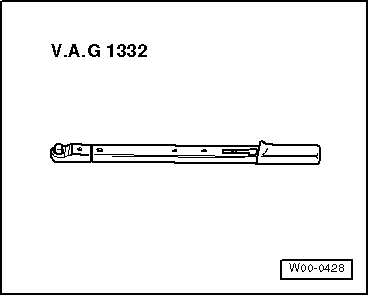

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required |

|

|

|

|

|

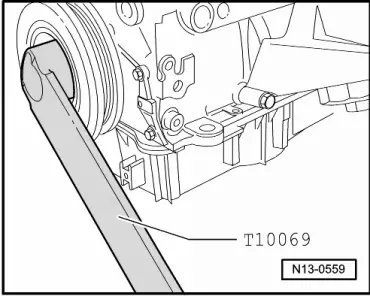

Removing |

|

|

Installing

|

|

|

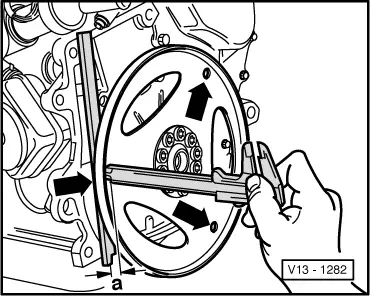

If the specification is not attained: |

|

|

Note: Only one shim of the appropriate thickness may be used. If the specification is attained:

|