Leon Mk1

|

| Check the tool and equipment equivalence table according to the applicability between Seat / VW / Audi / Skoda → Chapter. |

| Special tools and workshop equipment required |

| t | Torque wrench -V.A.G 1331-, see equivalent → Anchor. |

| t | Torque wrench -V.A.G 1332-, see equivalent → Anchor. |

| t | Engine assembly crane -V.A.G 1383 A-, see equivalent → Anchor. |

|

|

|

|

|

Note

Note |

|

Note

Note

|

|

|

|

|

|

|

|

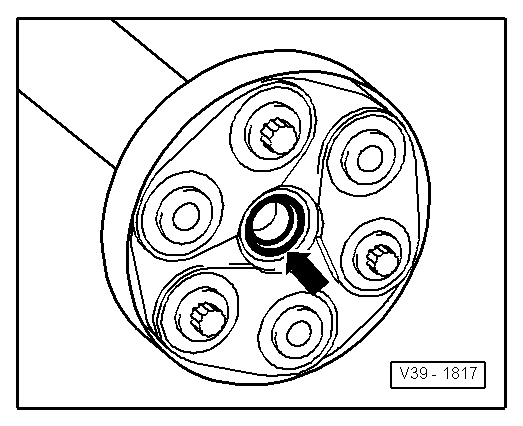

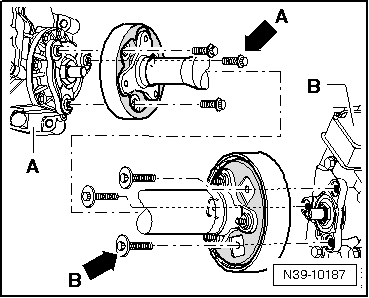

| Bolt with | Location |

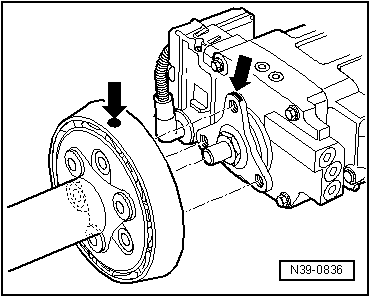

| small collar -arrow A- | cardan shaft to front final group -A- |

| large collar -arrow B- | cardan shaft to rear final group -B- |

|

Note

Note

|

|

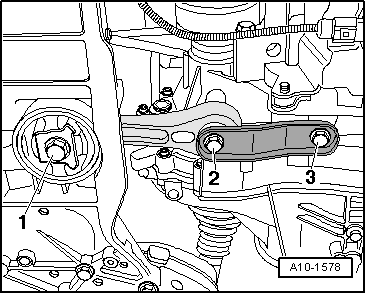

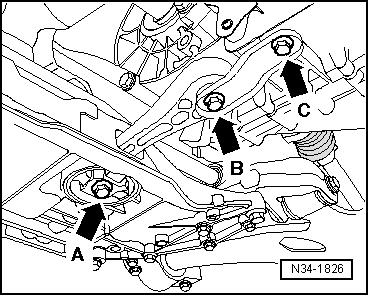

| Component | Nm | |||

Centre support to bodywork

| 25 | |||

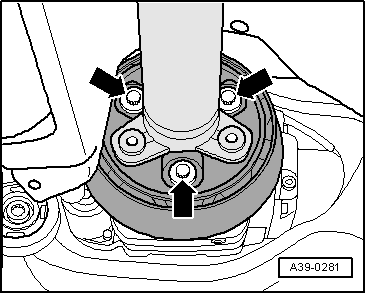

| Component | Nm | |||

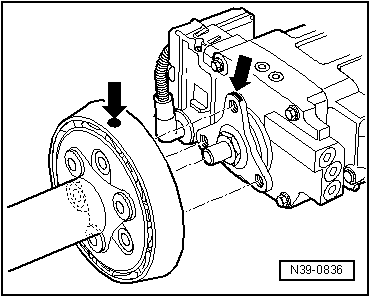

| Flexible disc to the rear final group | 60 | |||

Flexible discs to the cardan shaft

| 50 Nm + 90º (1/4 turn) | |||

| Flexible disc to the conical gear pair | 60 | |||

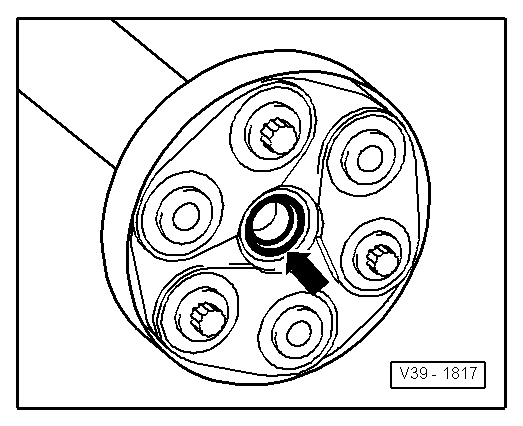

Caution

Caution