Note | t

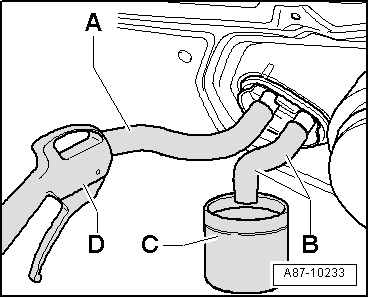

| The refrigerant must be extracted beforehand, e.g. with air conditioner service station -VAS 6007A- (or later model). |

| t

| Releasing refrigerant into the environment is a punishable offence. |

| t

| In vehicles with start-stop system, note abort conditions → Chapter. |

| Perform the following jobs: |

Note | t

| The coolant circuit must be bled after it is opened → Rep. gr.19. |

| t

| Cooling system is pressurized when engine is warm. If necessary, release pressure before carrying out repairs. |

| –

| Place drip tray -VAS 6208- beneath engine. |

| –

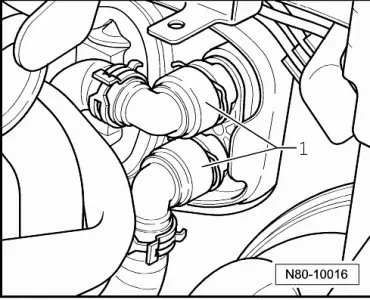

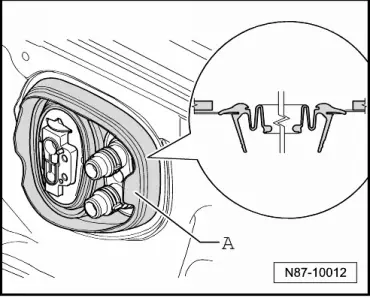

| Mark coolant hoses -1- to heater and air conditioning unit. |

WARNING | Danger of scalding injuries. |

| When the engine is warm, the coolant temperature may be above 100 °C. The cooling system is pressurised. |

| If necessary, release pressure and reduce temperature before carrying out repairs. |

|

|

|

|

Note

Note Note

Note

WARNING

WARNING