Leon Mk1

|

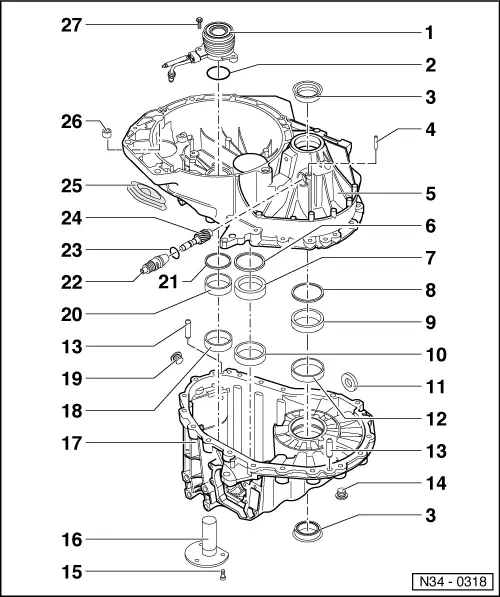

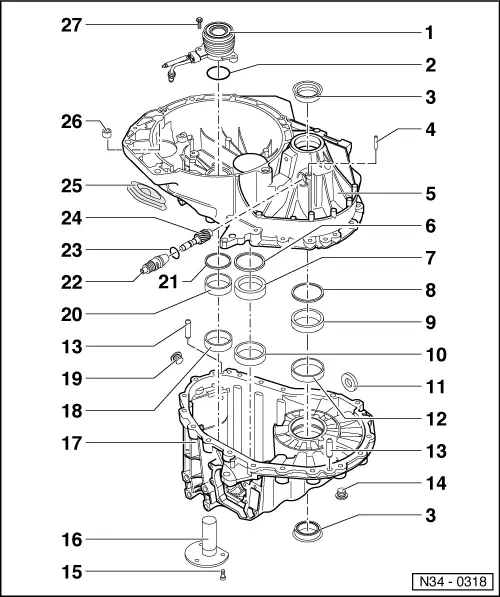

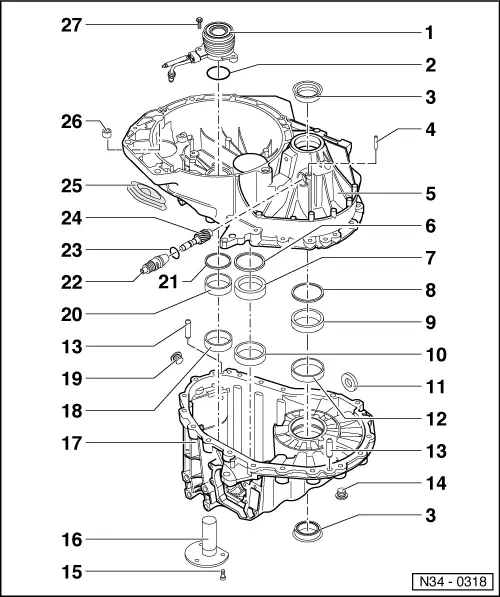

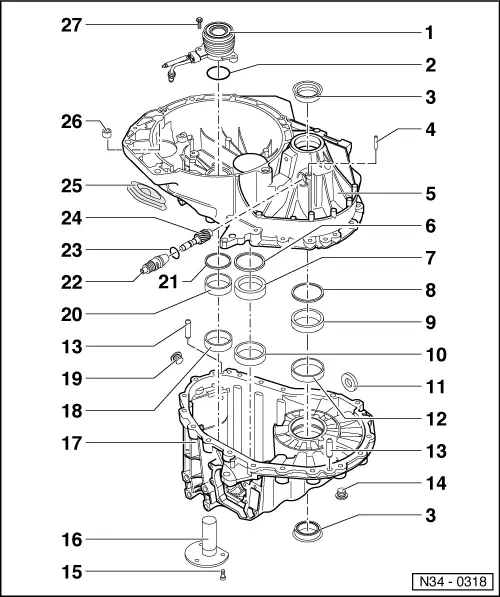

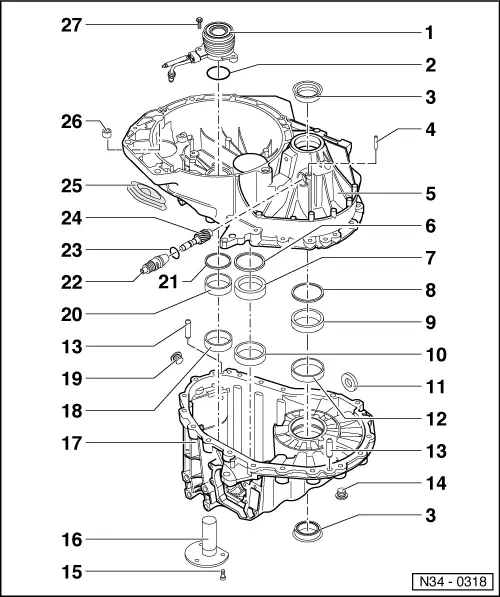

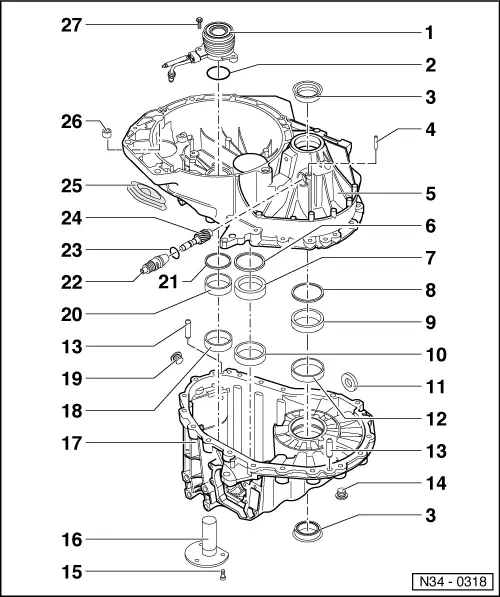

Servicing gearbox housing and clutch housing

Servicing gearbox housing and clutch housing

|

|

|

|

Note: Before pressing taper roller bearing outer raise in, heat relevant housing area to approx. 80 °C.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

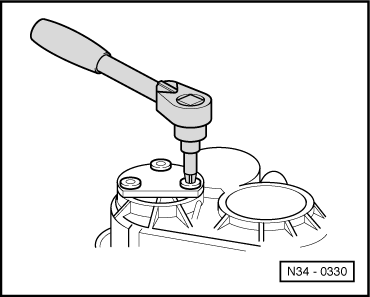

→ Fig.1 Removing reverse wheel shaft

Note: Support gearbox housing under bearing mounting with press plate VW 402. |

|

|

|

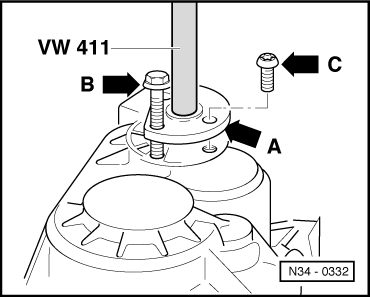

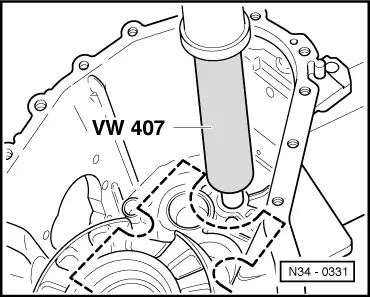

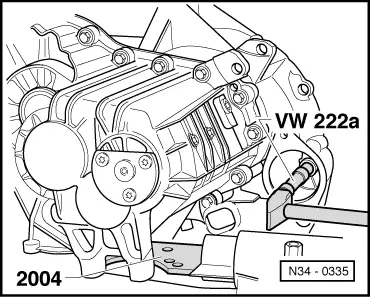

→ Fig.3 Securing reverse wheel shaft |

|

|

|

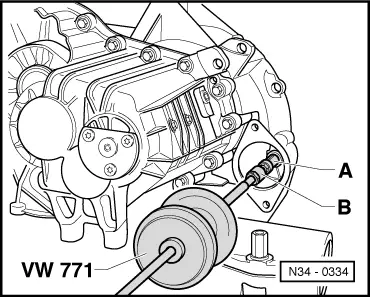

→ Fig.4 Pulling out starter bush. A - Internal puller 10...14 mm, e.g. Kukko 21/02 B - Threaded piece from counter support, e.g. Kukko 22/1 |

|

|

|

→ Fig.5 Knocking in starter bush. |