Leon Mk1

|

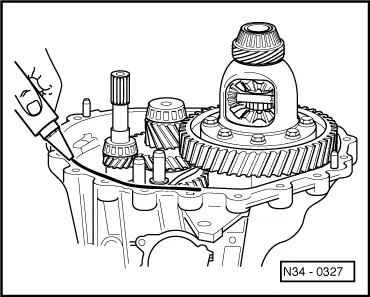

Dismantling and assembling gearbox

Dismantling and assembling sequence

|

|

|

|

Dismantling

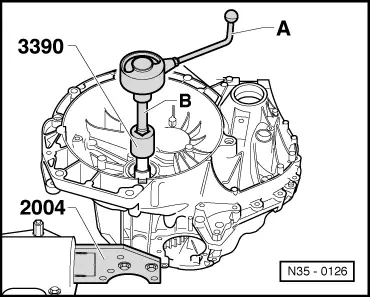

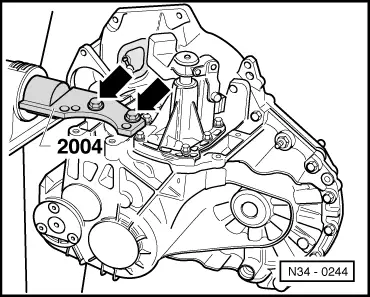

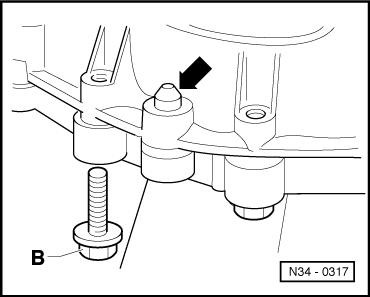

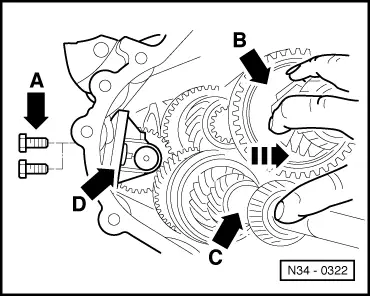

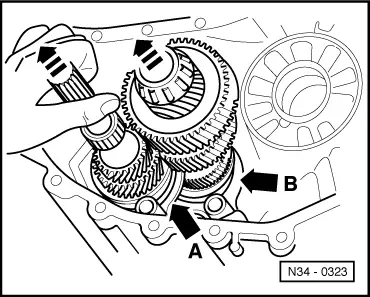

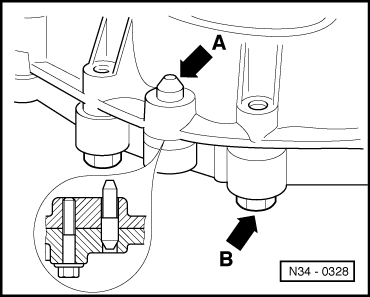

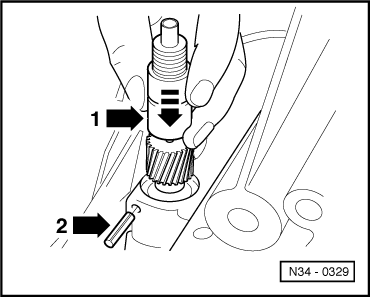

Note: Use M12 x 1.5 x 30 hexagon bolts (arrows).

|

|

|

|

|

|

|

|

|

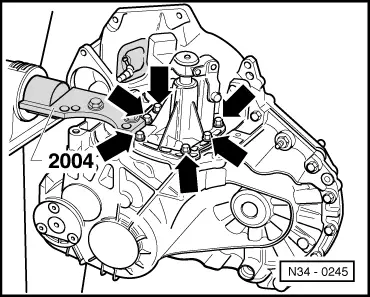

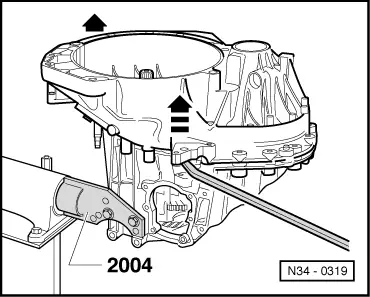

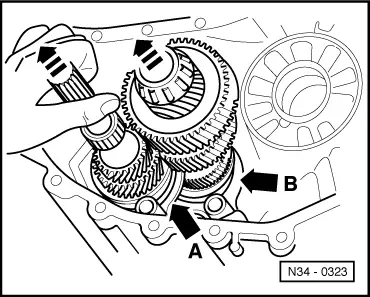

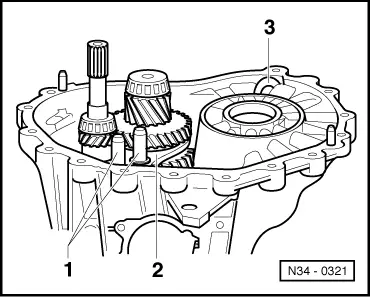

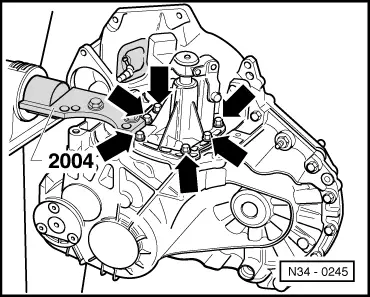

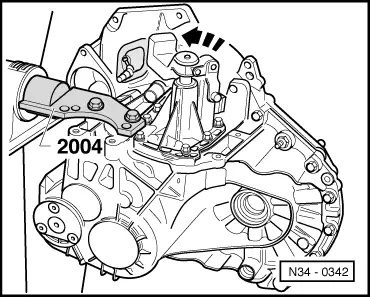

Note: Do not drive dowel pins out (arrow). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Assembling

|

|

|

|

|

|

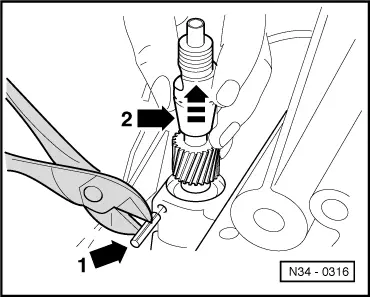

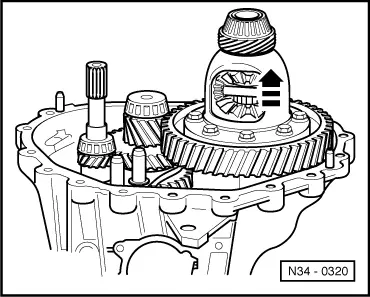

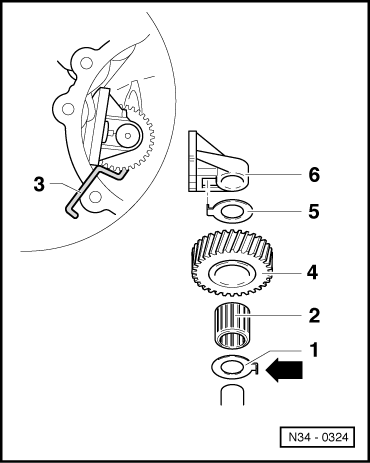

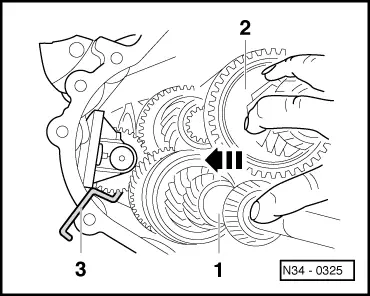

Note: Locking collars must be in neutral position.

|

|

|

|

|

|||||||

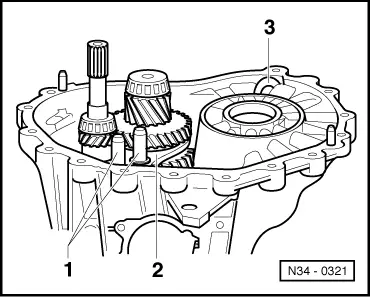

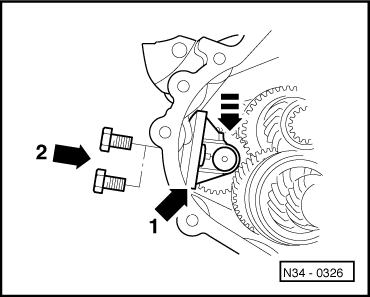

Note: Correctly installed selector rod ends are at same height. |

|

|

|

|

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

|