Leon Mk1

| Differential: dismantling and assembling |

| Special tools and workshop equipment required |

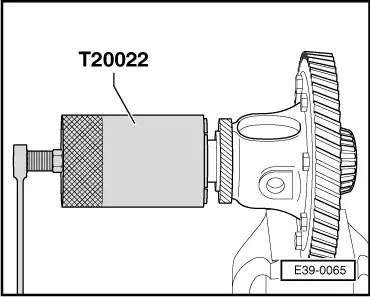

| t | Extractor -T20022- |

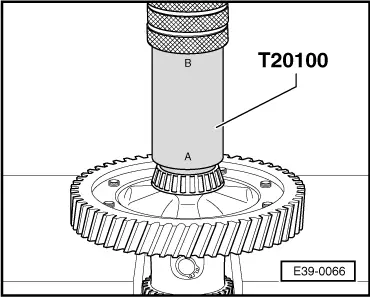

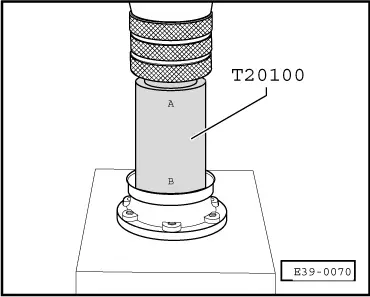

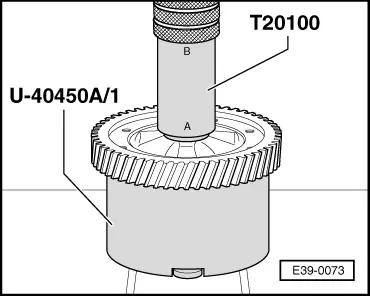

| t | Tool to fit interior tracks in the differential -T20100- |

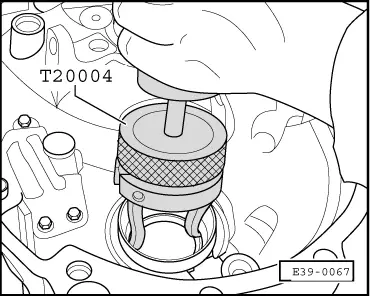

| t | Interior extractor with striker (2 legs) -T20004- |

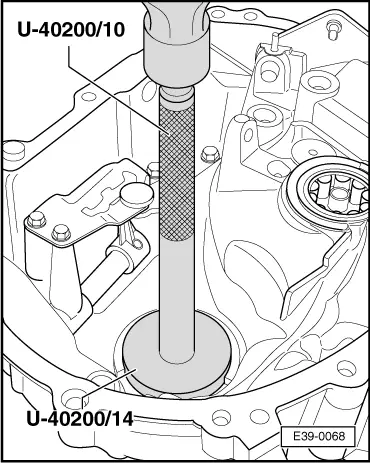

| t | Case -U-40200- |

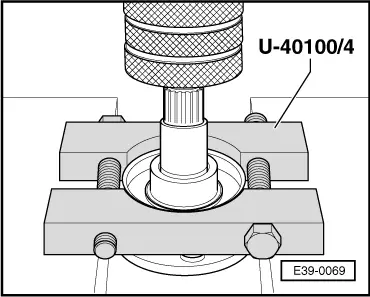

| t | Case -U-40100- |

| t | Case -U-40450A- |

Note!

Note!| t | Before fitting the interior rings of the conic roller bearings, heat to 100º C. |

| t | If necessary, replace the two conic roller bearings of the differential as a set. |

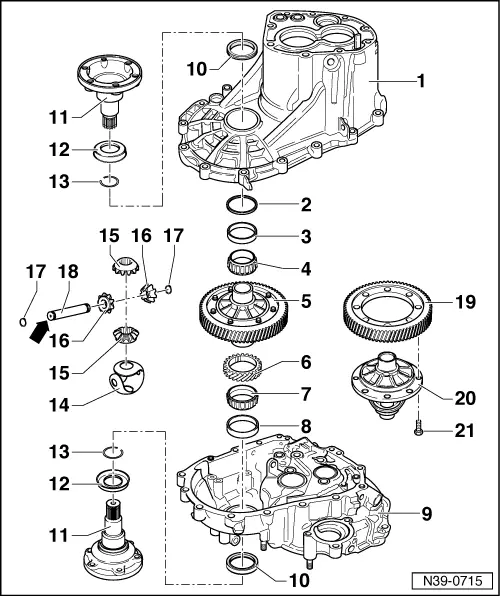

| 1 - | Gearbox housing |

| 2 - | Adjustment washer |

| q | For the differential |

| q | Determine the thickness → Chapter |

| 3 - | Exterior ring of the conic roller bearing |

| q | Extracting → Fig. |

| q | Fitting → Fig. |

| 4 - | Interior ring of the conic roller bearing |

| q | Extracting → Fig. |

| q | Fitting → Fig. |

| 5 - | Differential housing |

| q | The pinion for controlling the half-shafts is bolted to the differential housing |

| 6 - | Control pinion of the speedometer |

| q | Fit to the stop in the differential housing before fitting the interior ring of the bearing |

| 7 - | Interior ring of the conic roller bearing |

| q | Extracting → Fig. |

| q | Fitting → Fig. |

| 8 - | Exterior ring of the conic roller bearing |

| q | Extracting → Fig. |

| q | Fitting → Fig. |

| 9 - | Clutch housing |

| 10 - | Seal |

| q | Replace → Chapter |

| 11 - | Outlet shaft |

| q | Removing and refitting → Chapter |

| 12 - | Protection plate |

| q | For the gear change outlet shaft |

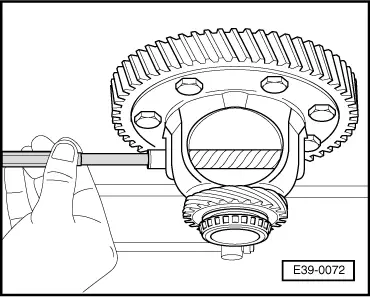

| q | Removing → Fig. |

| q | Fitting → Fig. |

| 13 - | Safety ring |

| q | Always replace |

| 14 - | Set of drive washers |

| q | Fit with gear oil |

| 15 - | Sun gear |

| q | Fitting → Fig. |

| 16 - | Satellite |

| q | Fitting → Fig. |

| 17 - | Safety ring |

| q | Replace |

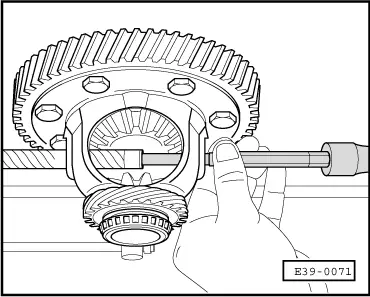

| 18 - | Satellite shaft |

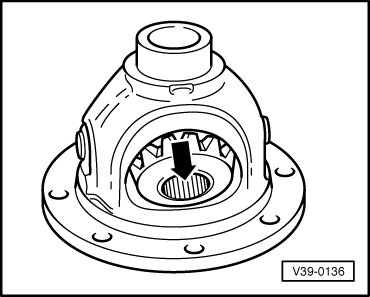

| q | The shaft has different diameters. The front with the centring hole -arrow- has a smaller diameter |

| q | Removing → Fig. |

| q | Fitting → Fig. |

| 19 - | Pinion for half-shaft control |

| q | This is twinned with the pinion of the secondary shaft and if replaced, the two must be replaced as a set |

| q | Removing → Fig. |

| q | Fitting position: the chamfered side of the threaded holes for the fitting bolts lies facing the differential housing |

| 20 - | Differential housing |

| 21 - | Hexagonal bolt, 80 Nm |

| q | These must be replaced when removed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|