Leon Mk1

| Clutch housing: repair |

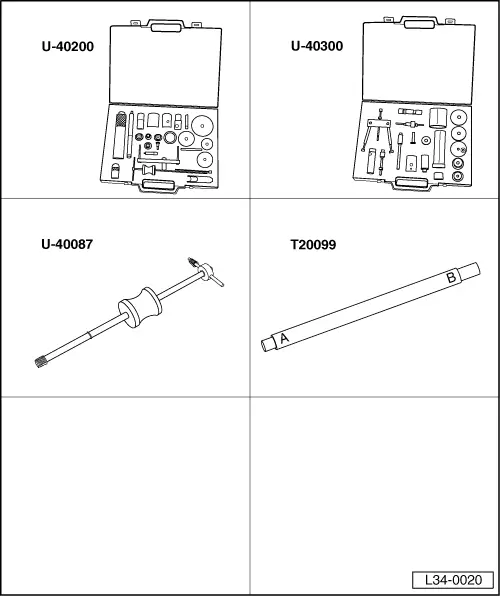

| Special tools and workshop equipment required |

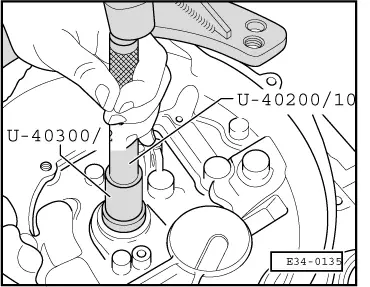

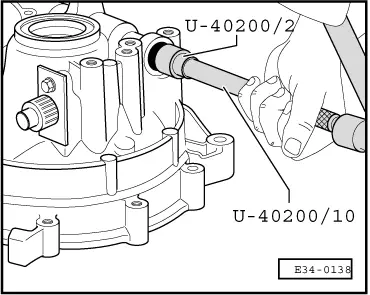

| t | Case -U-40200- |

| t | Case -U-40300- |

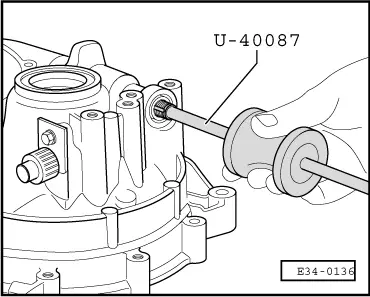

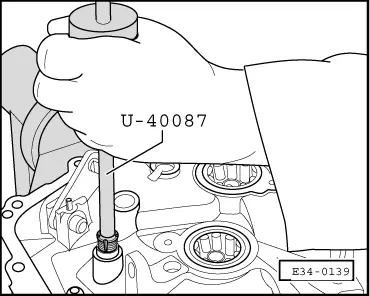

| t | Males for Ø 11 and Ø 14 with striker -U-40087- |

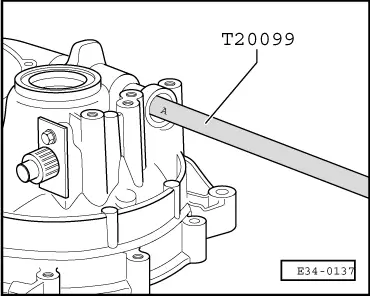

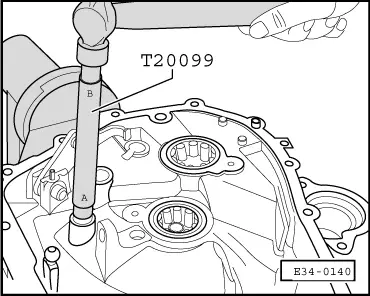

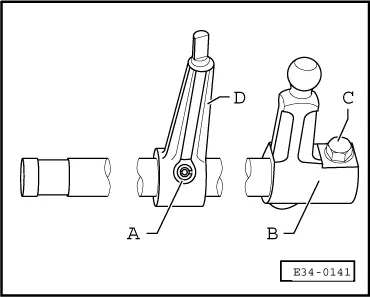

| t | Tool for removing/fitting bushings on the declutching shaft and selectors -T20099- |

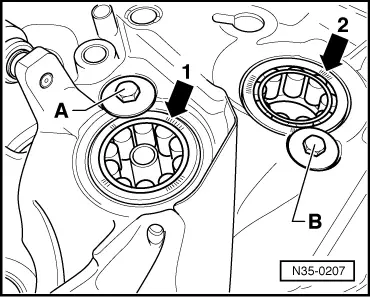

| 1 - | Stopper, 30 Nm |

| q | Screw in applying sealant paste -D 000 600 A2- |

| 2 - | Jointed lever shaft |

| q | Extract by hitting with a pole |

| 3 - | Jointed lever |

| 4 - | Shaft for the reverse gear lever |

| 5 - | Fixing pin |

| q | 4 x 25 mm |

| 6 - | Plug |

| 7 - | Reverse gear lever |

| 8 - | Retention ball |

| 9 - | Retention spring |

| 10 - | Cylindrical roller bearing |

| q | For the secondary shaft |

| q | Removing and refitting → Chapter |

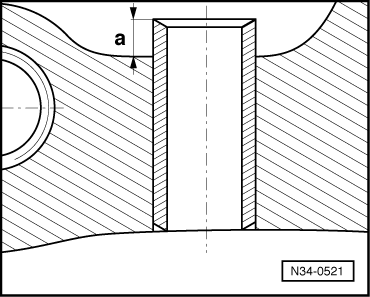

| q | Fitting position → Fig. |

| 11 - | Sleeve |

| q | For the oil guide |

| 12 - | Cylindrical roller bearing |

| q | For the secondary shaft |

| q | Removing and refitting → Chapter |

| q | Fitting position → Fig. |

| 13 - | Hexagonal bolt, 10 Nm |

| 14 - | Safety washer |

| 15 - | Late |

| 16 - | Clutch housing |

| 17 - | Breather pipe |

| q | Remove using pliers |

| q | Fit with a pole |

| q | Fitting position → Fig. |

| 18 - | Breather part |

| 19 - | Seal for the primary shaft |

| q | Removing → Fig. |

| q | Refitting → Fig. |

| 20 - | Guide sleeve |

| 21 - | Hexagonal bolt, 10 Nm |

| q | Screw in applying sealant paste -D 000 600 A2- |

| 22 - | Threaded bolt M10×55 |

| 23 - | Threaded bolt M10×70 |

| 24 - | O-ring |

| q | Always replace |

| 25 - | Guide bushing |

| 26 - | Support |

| 27 - | Safety washer |

| 28 - | Hexagonal nut, 10 Nm |

| 29 - | Seal for outlet shaft |

| q | Changing → Chapter |

| 30 - | Pinion for speedometer |

| 31 - | Bolt |

| q | For the control cable |

| q | Screw into the gearbox |

| 32 - | Bearing bushing |

| q | For the gear selector shaft |

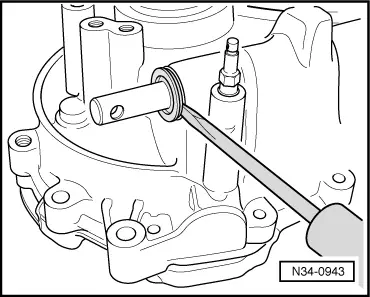

| q | Extracting → Fig. |

| q | Fitting → Fig. |

| 33 - | Seal |

| q | For the gear selector shaft |

| q | This can be changed with the gearbox in place |

| q | Removing → Fig. |

| q | Refitting → Fig. |

| 34 - | Gear selector shaft |

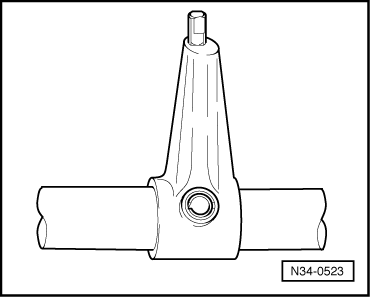

| 35 - | Slide arm |

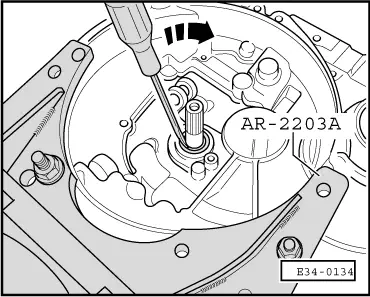

| q | Removing, refitting and fitting position → Fig. |

| 36 - | Fixing pin |

| q | 5 x 22 mm |

| q | Fitting position → Fig. |

| 37 - | Fixing pin |

| q | 3 x 22 mm |

| q | Fitting position → Fig. |

| 38 - | Magnet |

| q | Held between the two housings of the gearbox |

| 39 - | External ring of the conic roller bearing |

| q | For the differential |

| q | Removing and refitting → Chapter |

| q | If changed, the differential should be adjusted → Chapter |

| 40 - | Guide slide |

| 41 - | Safety washer |

| 42 - | Hexagonal bolt, 10 Nm |

| 43 - | Gear change lever |

| q | Removing, refitting and fitting position → Fig. |

| 44 - | Hexagonal bolt, 10 Nm |

| q | Screw in applying sealant paste -D 000 600 A2- |

| 45 - | Safety washer |

| 46 - | Bearing bushing for control bar |

| q | Removing → Fig. |

| q | Refitting → Fig. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|