| t

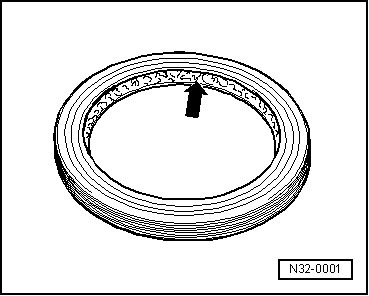

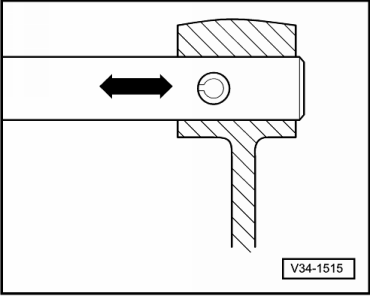

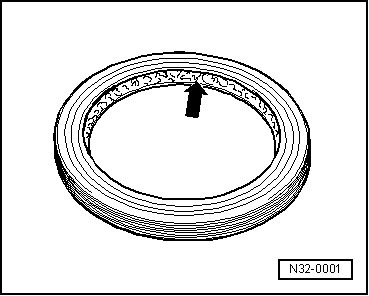

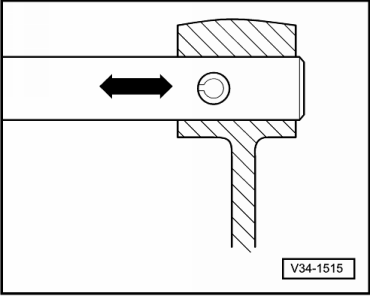

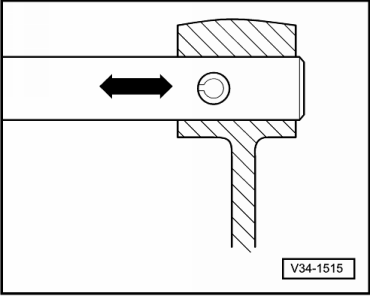

| When fitting the elastic pins, the groove must be positioned longitudinally with respect to the force trajectory, as shown in the figure. |

| t

| Always loosen and tighten the bolts and nuts in a cross when fitting covers and housings. With delicate parts, such as the clutch press for instance, do not incline them and proceed gradually. |

| t

| The torques indicated refer to unoiled nuts and bolts. |

| t

| Self-locking bolts and nuts must always be replaced. |

| t

| Needle bearings must be fitted with the thickest side towards the fitting shaft-tool. |

| t

| All gearbox bearings must be fitted impregnated in gear oil. Take special care when oiling for friction torque measurements. |

| t

| Bearings belonging to the same shaft must be replaced as a unit. Use brands by the same manufacturer as far as possible. |

| t

| To fit bearings, they should first be heated to 100 ºC approximately. Use the -SAT 1416- electroblower and the digital thermometer -SAT 4002- to check the temperature. |

| t

| Do not mix or exchange the exterior tracks of bearings of the same size; bearings come in pairs. |

| t

| Before fitting the adjustment washers, their thickness must be checked by using a micrometer to measure the surface at various points. |

| t

| The existence of washers with adjusted tolerances allows the required thickness of the washer to be known precisely. |

| t

| Washers must have no burrs or be damaged in any way. |

| t

| Only fit adjustment washers in a perfect condition. |

| t

| Do not mix the synchroniser rings of different gears. If they have to be reused, fit them to the same gear as before. |

| t

| Check for wear and replace if necessary. |

| t

| To fit, impregnate in gear oil. |

| t

| Before fitting, clean with the utmost care. Gears must first be heated to 100 ºC approximately. Use the -SAT 1416- electroblower and the digital thermometer -SAT 4002- to check the temperature. |

|

|

|