Leon Mk1

| Differential: dismantling and assembling |

| Special tools and workshop equipment required |

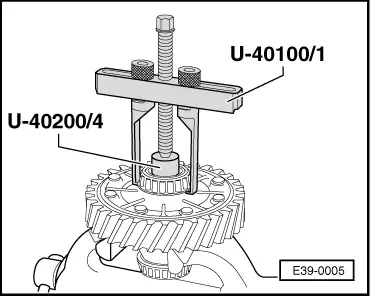

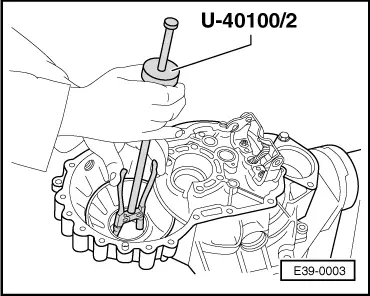

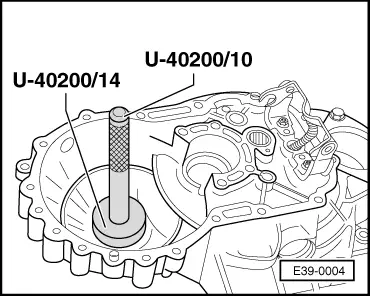

| t | Gearbox extractor set -U-40100- |

| t | Gearbox repair set -U-40200- |

| t | Clip extractor with claws -T20022- |

| t | Electric blower -SAT 1416- |

| t | Digital thermometer -SAT 4002- |

Note!

Note!| t | Heat the inner roller bearing track to 100 °C before fitting |

| t | The two roller bearings should be replaced together |

| t | Adjust the differential whenever the roller bearings, differential casing, gearbox casing or clutch housing are replaced → Chapter |

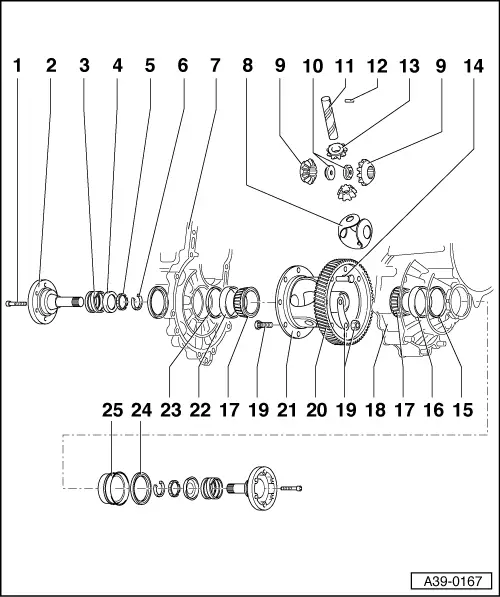

| 1 - | Bolt |

| q | 25 Nm |

| q | Bolt with the threaded device for securing the articulation flanges, → Item |

| 2 - | Articulation flange |

| q | Removing and fitting → Chapter |

| 3 - | Articulation flange spring |

| q | Fit behind the articulation flange |

| 4 - | Thrust washer |

| q | Assembly position: Collar towards the spring, core towards the conical ring |

| 5 - | Conical ring |

| q | With recess for the thrust washer |

| q | Assembly position: conical side facing the differential casing |

| 6 - | Safety ring |

| q | Maintains the position of the conical ring, washer and spring of the articulation flange when dismantled |

| 7 - | Gearbox casing |

| 8 - | Set of thrust washers |

| q | Fit with gear oil |

| 9 - | Planet gear |

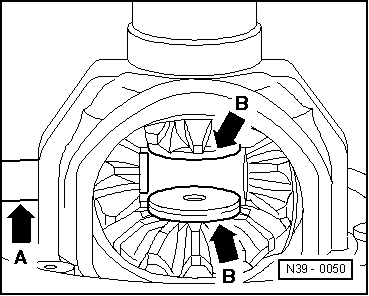

| q | Fit → Fig. |

| 10 - | Threaded component to secure the articulation flanges |

| q | Fit → Fig. |

| 11 - | Satellite shaft |

| q | Remove with a drift |

| q | Fit → Fig. |

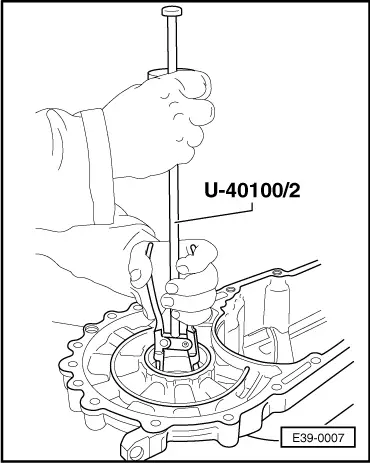

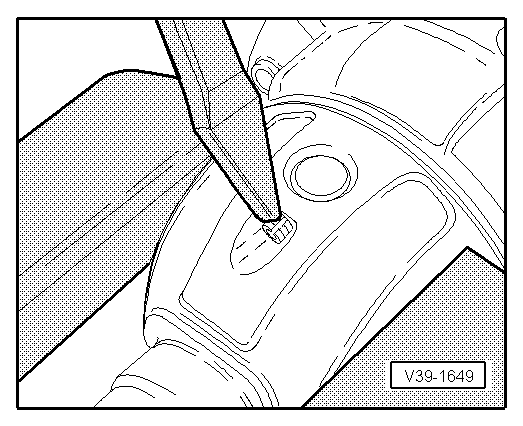

| 12 - | Securing pin |

| q | To hold the satellite shaft |

| q | Renew |

| q | Removing and installing → Fig. |

| 13 - | Satellite |

| q | Fit → Fig. |

| 14 - | Rivet |

| q | Only for factory production |

| q | Drill → Chapter, Differential crown: removing and installing |

| 15 - | Shim S2 |

| q | Always 1 mm thick |

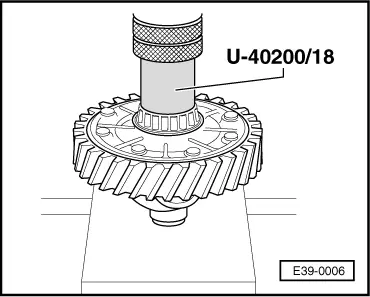

| 16 - | Outer track, roller bearing |

| q | Remove → Fig.; first remove the bush → Item |

| q | Fit → Fig. |

| 17 - | Roller bearing |

| q | Remove → Fig. |

| q | Fit → Fig. |

| 18 - | Clutch housing |

| 19 - | Repair kit |

| q | Only for post-sale service |

| q | Bolt assembly → Chapter, Differential crown: removing and installing |

| q | Hexagon nut, 65 Nm |

| 20 - | Differential crown |

| q | Rivetted in the factory |

| q | A matched pair with the layshaft, if it needs replacing they must both be replaced |

| q | Removing and fitting → Chapter |

| 21 - | Differential casing |

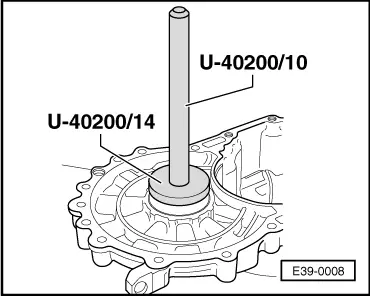

| 22 - | Outer track, roller bearing |

| q | Remove → Fig. |

| q | Fit → Fig. |

| 23 - | Shim S1 |

| q | Determine thickness → Chapter, Differential: adjustment |

| 24 - | Articulation flange oilseal |

| q | Renew → Chapter |

| 25 - | Bush |

| q | To house the articulation flange oilseal |

| q | Removing and fitting → Chapter, Clutch housing: repairing |

|

|

|

|

Note!

Note!

|

|

|

|

|

|

|

|

|

|