Leon Mk1

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

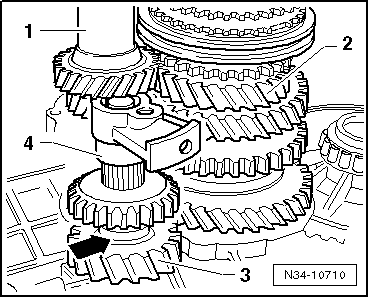

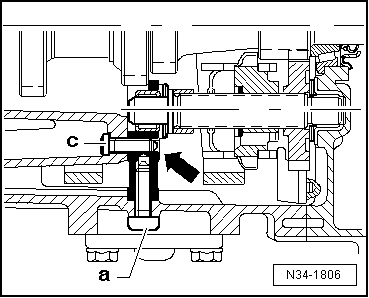

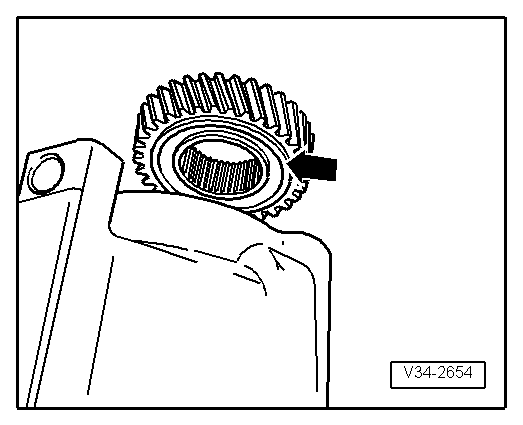

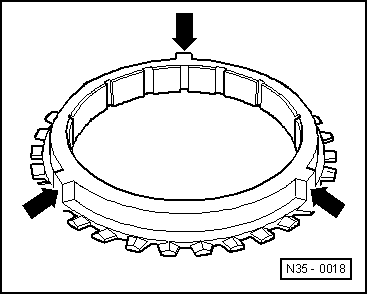

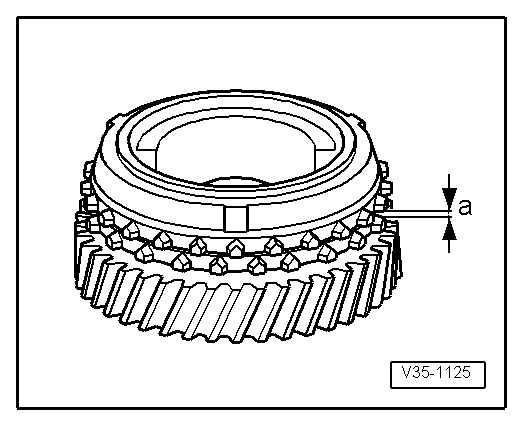

| Synchro-ring | Measurement „a“ in new synchro | Wear limit |

| 5. gear | 1.1 ... 1.7 mm | 0.5 mm |

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

WARNING

WARNING