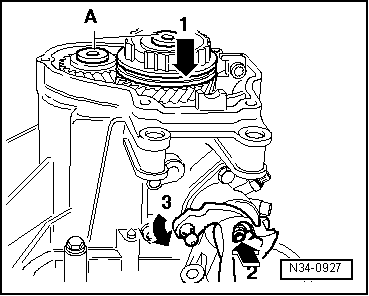

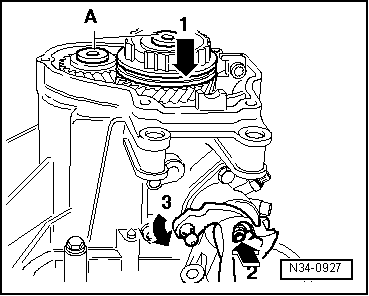

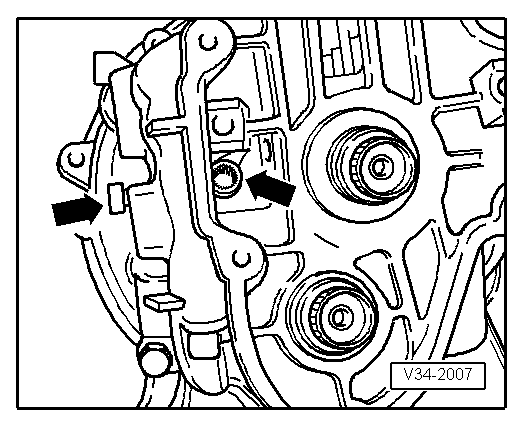

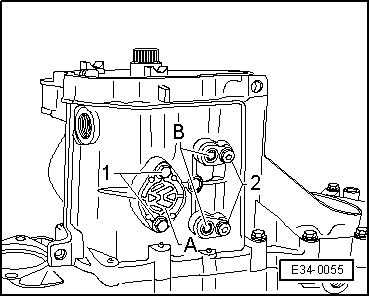

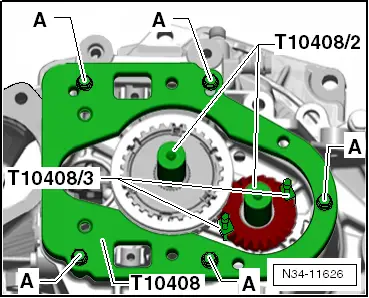

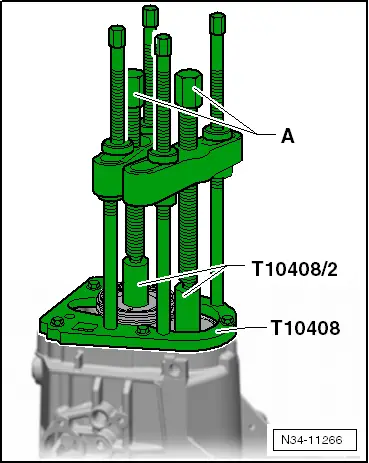

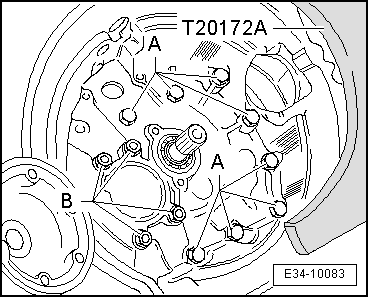

| In order to slacken the two fixing bolts -A- securing 5th gear sprocket and synchromesh, take the following steps: |

| –

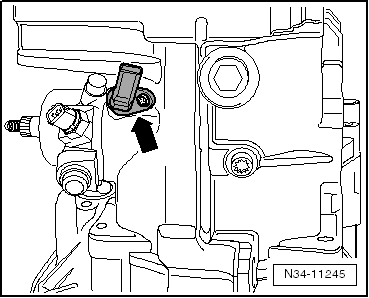

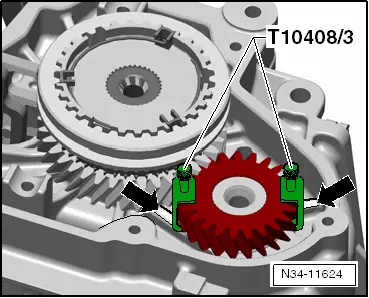

| Press the locking collar of 5th gear -arrow 1- downwards. |

| –

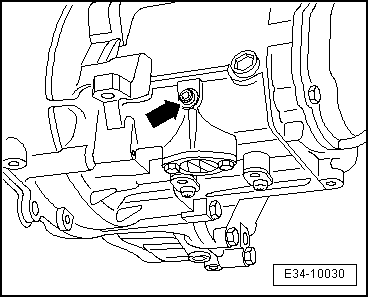

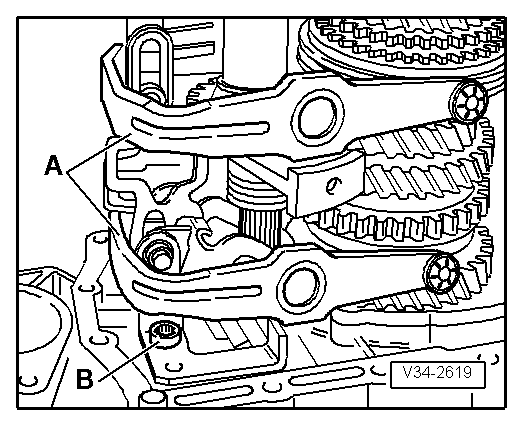

| Also connect the 1st gear by pressing the selection drive shaft inwards -arrow 2- and turning it -arrow 3-. |

| l

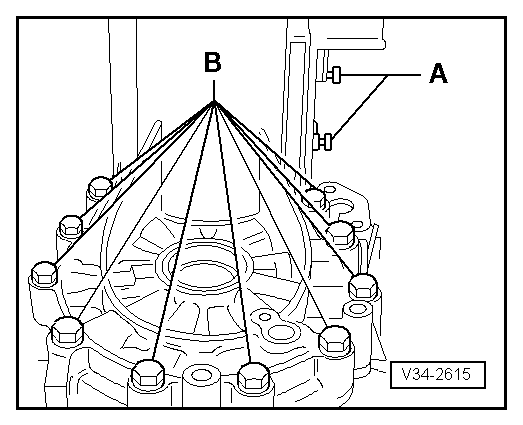

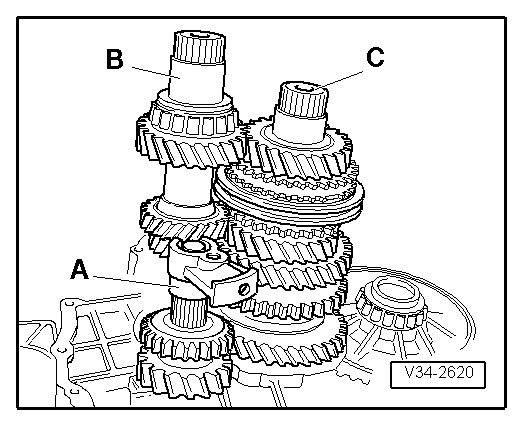

| After both gears are engaged, the input shaft and output shaft are locked. The synchro-hub and gear wheel cannot turn. |

| –

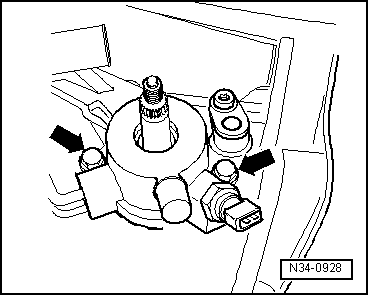

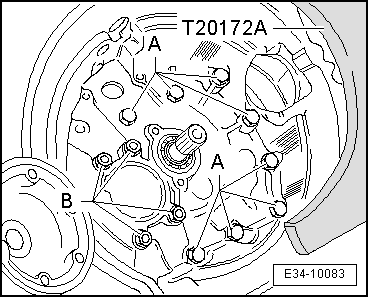

| Slacken and remove bolts -A-. |

Note | If shafts are not to be renewed, carefully clean residual locking material out of the tapped holes using a thread tap. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution