| –

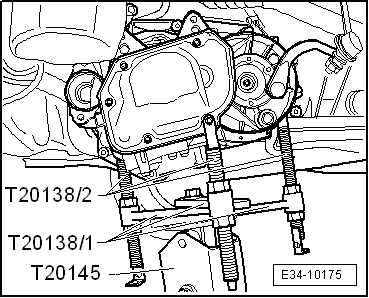

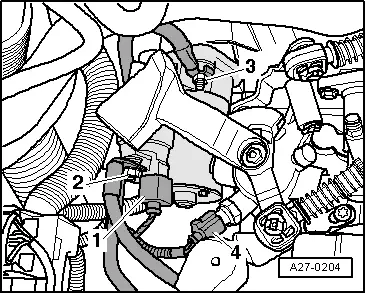

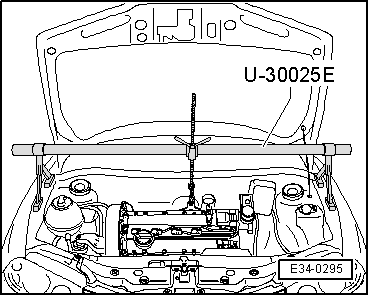

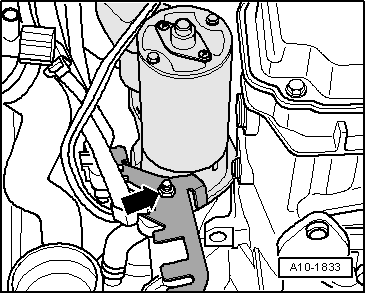

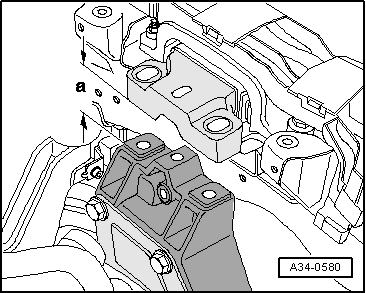

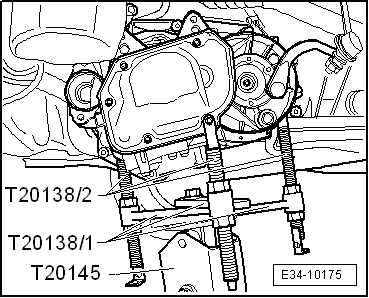

| Attach the support tool -T20138C- on the base -T20145-, and move these onto the engine and gearbox jack -SAT 1040- using the adapter for the hydraulic engine and gearbox jack -SAT 1001/1-. |

| –

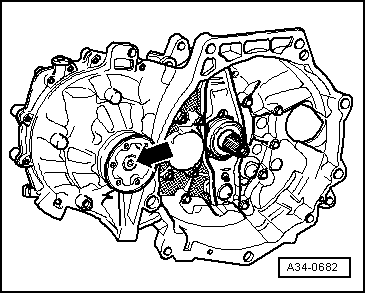

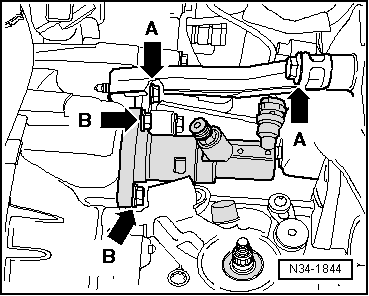

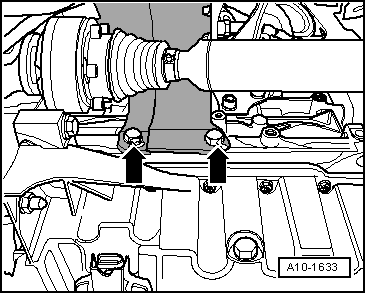

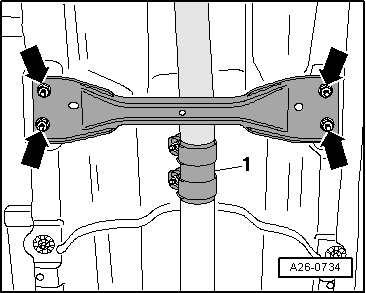

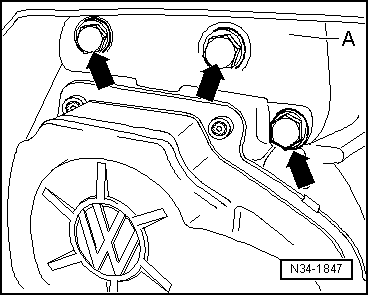

| Fix the gearbox support -T20138C- to gearbox -arrows- |

| –

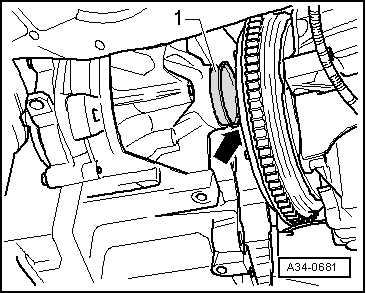

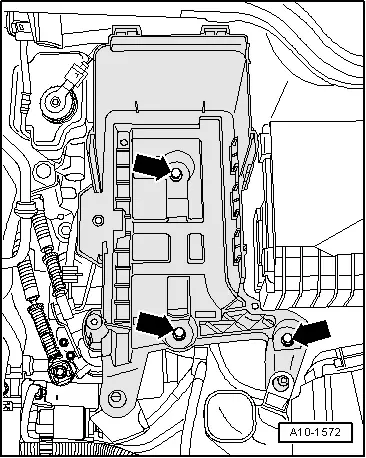

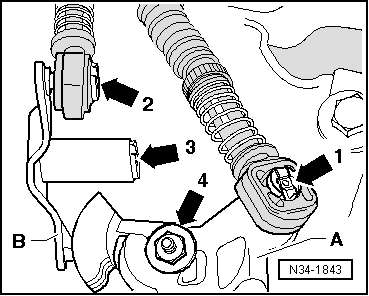

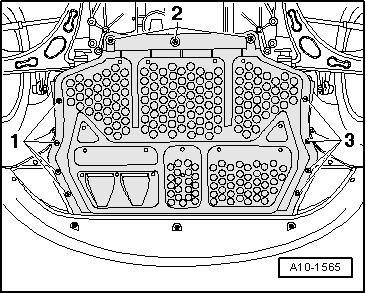

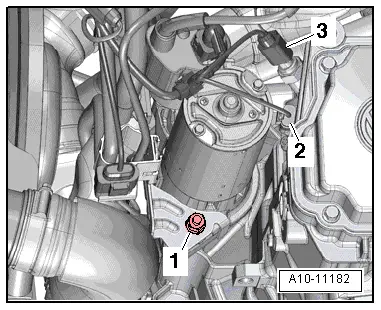

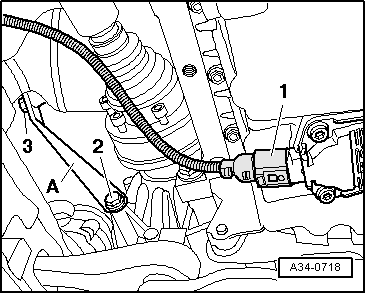

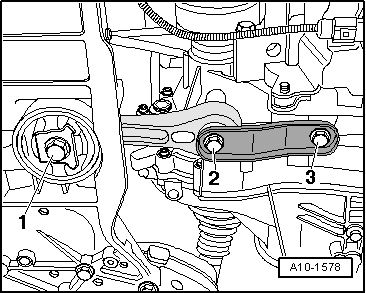

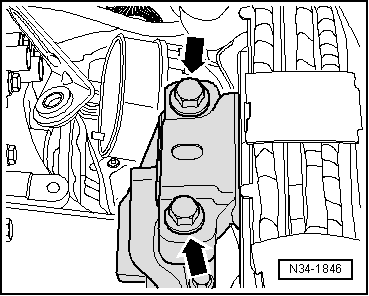

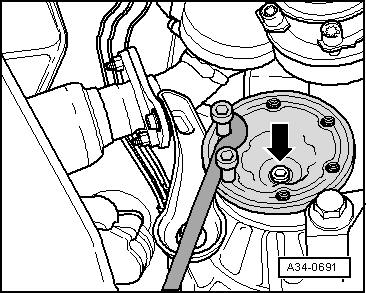

| Remove gearbox securing bolts by lower part, disengage gearbox from guide sleeves. |

| –

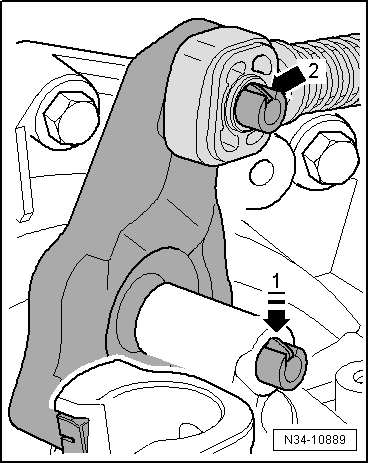

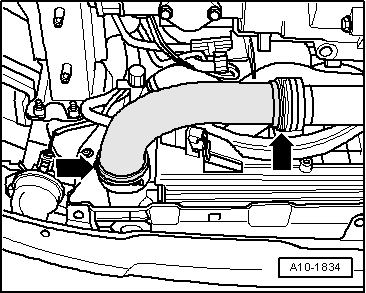

| Adjust the gearbox support -T20138C- in such a way that the gearbox moves without force on the rigid drive shaft, at the same time separating gearbox from engine. |

| –

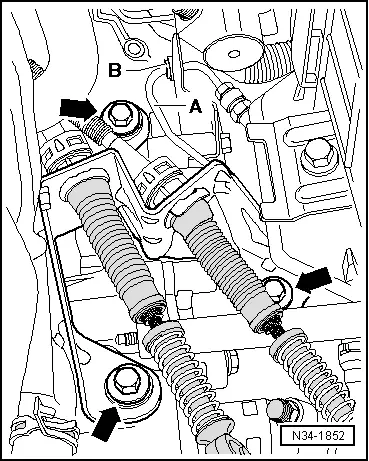

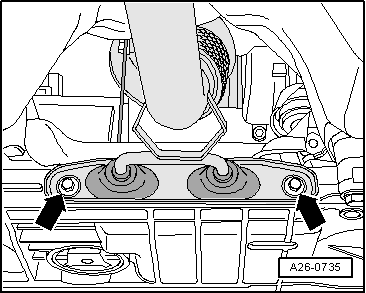

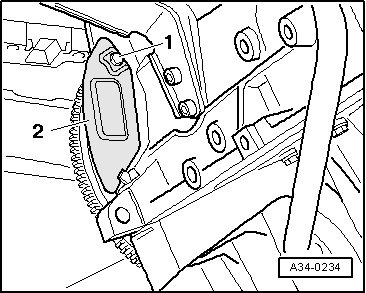

| Swing gearbox forwards on adjustment spindle. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note