Note! | t

| When fitting the camshaft, the cylinder 1 cams must point upwards. |

| t

| Do not swap the worn half bearings (mark them). |

| t

| When fitting the camshaft, check that the mounting flanges of the half bearings seat correctly in the caps and the cylinderhead. |

| t

| Before installing the cap, check that the cylinderhead washers are fitted on the cylinderhead. |

| –

| Lubricate the slide surfaces of the half bearings. |

| –

| Tighten caps 2 and 3 alternately and crosswise to a torque of 8 Nm + 1/4 turn (90°) |

| –

| Fit caps 1 and 4 and tighten them to a torque of 8 Nm + 1/4 turn (90°) too. |

Note! | t

| Cap 4 is marked as cap 5. |

| t

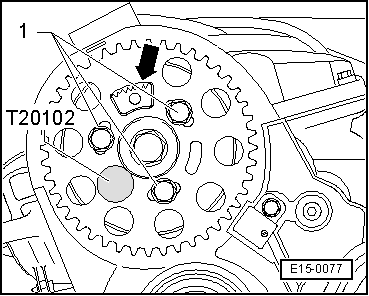

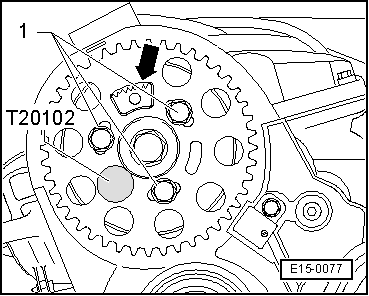

| Seal the contact surfaces of caps 1 and 4 with -AMV 17400401- → Fig.. |

| t

| Cap 4 must be flush with outer edge of the cylinderhead: otherwise the tandem pump may leak. |

| –

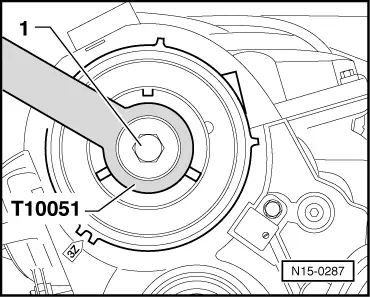

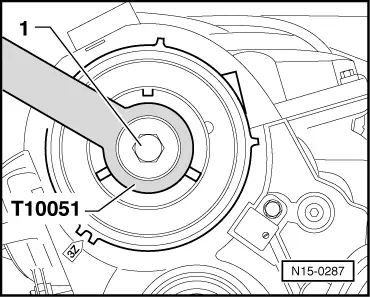

| Replace the rocker shaft bolts. |

| –

| Fit the rocker shaft tighten the two inner bolts first and then the outer ones, uniformly and crosswise, until there is no play in the housing. Tightening torque 20 Nm + 1/4 turn (90°) |

|

|

|

Note!

Note! Note!

Note!

Note!

Note! Note!

Note!

Note!

Note! Note!

Note!

Note!

Note! Note!

Note!