Leon Mk1

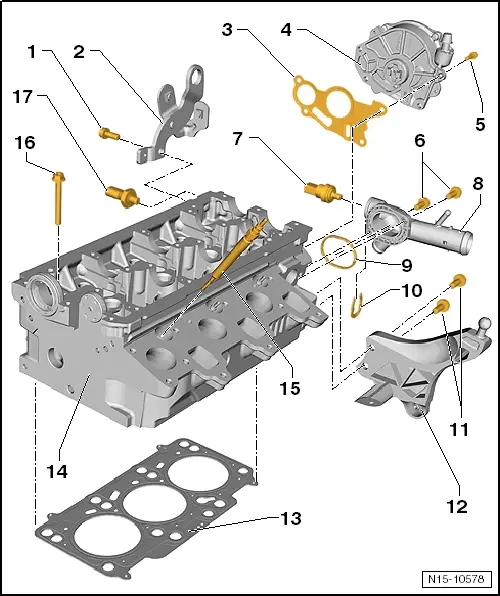

| 1 - | 25 Nm |

| 2 - | Attachment rings |

| 3 - | Seal |

| q | Replace |

| 4 - | Vacuum pump |

| 5 - | 10 Nm |

| 6 - | 10 Nm |

| 7 - | Coolant temperature sender -G62- |

| 8 - | Coolant connections |

| 9 - | O ring |

| q | Replace |

| 10 - | Clip |

| 11 - | 25 Nm |

| 12 - | Spring retainer |

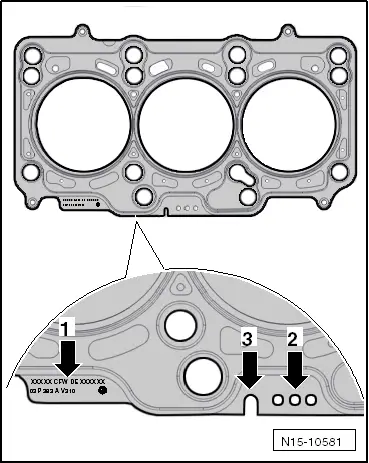

| 13 - | Cylinder head gasket |

| q | Replace |

| q | Note marking → Fig.. |

| q | If renewed, change coolant in entire system |

| 14 - | Cylinder head |

| q | removing and installing. → Chapter |

| q | If renewed, change coolant in entire system |

| 15 - | Glow pin plug, 18 Nm |

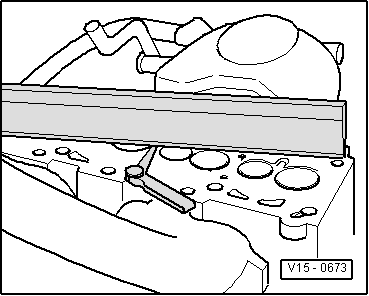

| 16 - | Cylinder head bolt |

| q | Observe sequence when loosening and tightening → Chapter. |

| q | Prior to installation, insert washers in cylinder head |

| 17 - | Oil pressure switch -F1-, 22 Nm |

| q | Identification: green |

| q | 0.5 bar |

| q | In case of leakage, cut out and replace sealing ring |

| q | Checking → Chapter |

Note

Note

|

|

Note

Note

|

|