| –

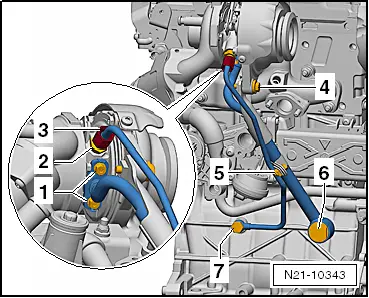

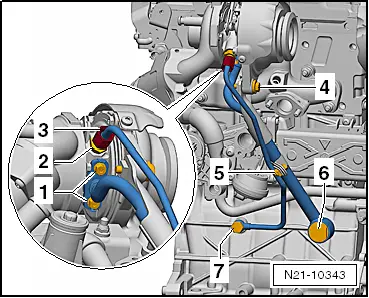

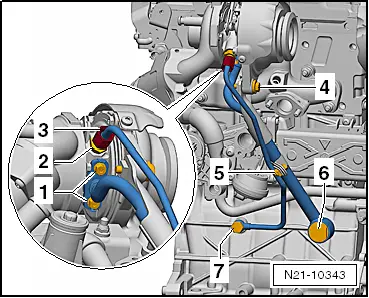

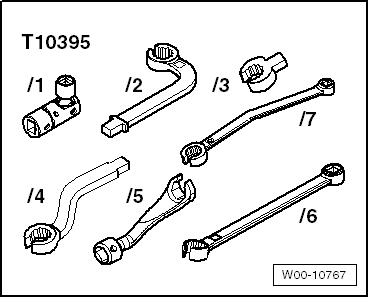

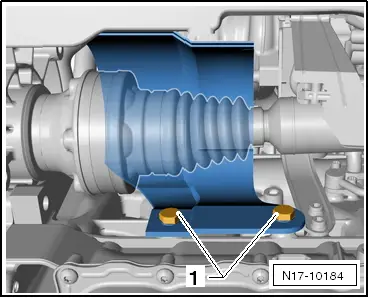

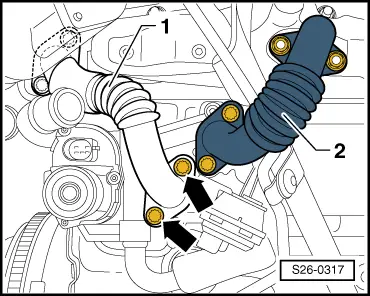

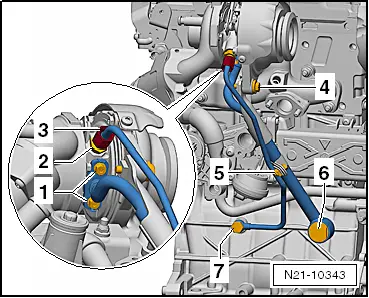

| Unscrew the bolts -1, 4 and 5- and the banjo bolts -6, 7-. |

| –

| Remove turbocharger support and oil supply line. |

Note | l

| The procedure must be adhered to, in order to ensure that the oil supply line and oil return (turbocharger support) are installed tension-free. |

| l

| Furthermore this ensures that the turbocharger support is installed tension-free between crankcase and turbocharger. |

| –

| First retighten the oil return line and oil return (turbocharger support) on the crankcase and turbocharger by hand. |

| –

| Position oil supply line on crankcase and turbocharger. |

| –

| Then tighten oil return line and oil return (turbocharger support) in several steps up to the specified torque, alternating between the crankcase and turbocharger. |

| –

| Then tighten the banjo bolt for oil supply line on crankcase and union nut on turbocharger in several steps up to the specified torque, alternating between the crankcase and turbocharger. |

| –

| Finally tighten bolt on oil supply line/turbocharger support clamp to specified torque. |

| –

| Remaining assembly is performed in reverse sequence. |

|

|

|

Note

Note

Note

Note