Leon Mk1

| 1 - | Camshaft housing |

| q | Sealing surface must not be reworked. |

| q | With integrated camshaft bearings |

| q | removing and fitting → Chapter |

| q | Remove old sealant residues |

| q | Before mounting, apply D 154,103 A1 |

| q | To fit, place vertically with the adjustment bolts in the cylinder head holes |

| 2 - | cylinder block |

| q | 2-part |

| q | The bolts must not be loosened |

Note

Note| Do not remove the piston. |

| 3 - | Balancing shaft |

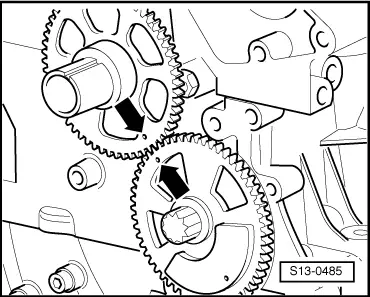

| 4 - | Pinions |

| q | Do not remove |

| q | for balance shaft |

| q | Installation position for the crankshaft pinion with regard to the balance shaft pinion → Fig. |

| 5 - | Oil pump: |

| q | Always replace completely |

| q | removing and fitting → Chapter |

| 6 - | Guide pin, 20 Nm |

| 7 - | Guide rail |

| q | For distribution chain → Item |

| 8 - | Pinions |

| q | For crankshaft |

| 9 - | Pinions |

| q | For oil pump drive |

| 10 - | Chain for oil pump |

| q | Before removing, mark direction of rotation (installation position). |

| 11 - | Pinions |

| q | For oil pump |

| q | Adjust distribution timing → Chapter. |

| 12 - | Oil pan |

| q | Remove and install on engines with liquid gasket → Chapter. |

| q | Clean sealing surface before installing |

| q | Install with silicone sealant D 176,404 A2 |

| 13 - | Bolt, 9 Nm |

| 14 - | Cover |

| q | Chain sprockets for operating the oil pump |

| 15 - | 20 Nm and then turn 90° further |

| 16 - | O ring |

Note

Note| Always replace the O-ring after dismounting |

| 17 - | Mounting bush |

| 18 - | Oil seal |

| q | removing and fitting → Chapter |

| 19 - | Pulley |

| q | Do not tilt during assembly |

| q | Poly-V belt: removing and installing → Chapter |

| 20 - | 150 Nm and then turn 180° further |

| q | Replace |

| q | Lubricate |

| q | Secure pulley with retaining tool -3415- |

| q | When tightening, lock the crankshaft with the crankshaft stop -T10121-. |

| q | The turning further angle can be checked using a commercial protractor e.g. Hazet 6690. |

| 21 - | 25 Nm |

| 22 - | 50 Nm |

| 23 - | 10 Nm |

| 24 - | To intake manifold |

| 25 - | 10 Nm |

| 26 - | Oil separator |

| q | With heated vacuum valve |

| 27 - | O ring |

| q | Replace if damaged |

| 28 - | Distribution housing |

| q | removing and fitting → Chapter |

| q | Install with sealant D 174.003 A2 |

| q | Screw two stud -M6x75- into cylinder head and cylinder block to improve guidance. |

| q | Fix the oil sump with two bolts to ease the fitting of the distribution casing. |

| 29 - | Cover cap |

| 30 - | O ring |

| q | Replace if damaged |

| 31 - | 50 Nm and then turn 90° further |

| 32 - | Tensioning plate |

| 33 - | Chain tensioner |

| 34 - | 9 Nm |

| 35 - | Timing chain |

| q | A roller chain is installed for engines with identification letters BZG. |

| q | A toothed chain will be fitted in engines with engine code CGPA and CGPB. |

| q | removing and fitting → Chapter |

| 36 - | Pinions |

| q | For camshaft |

|

|

Caution

Caution