| –

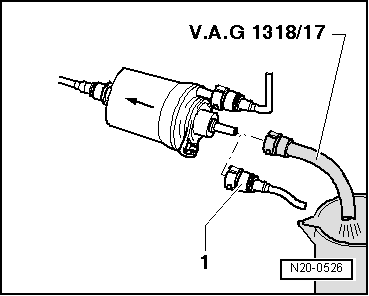

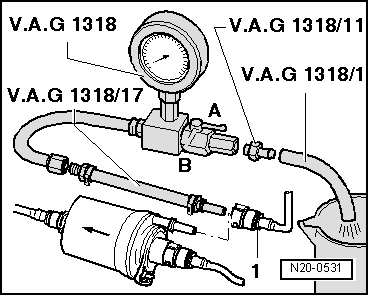

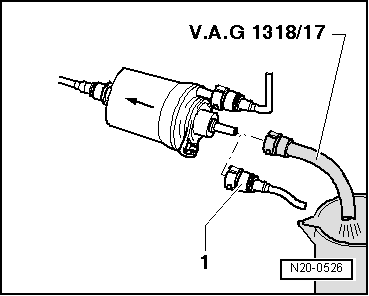

| Pull supply hose -1- off inlet to fuel filter. |

Note | Press in safety ring to release fuel lines. |

| –

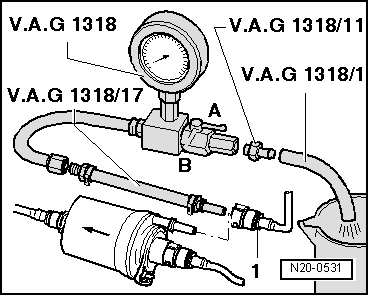

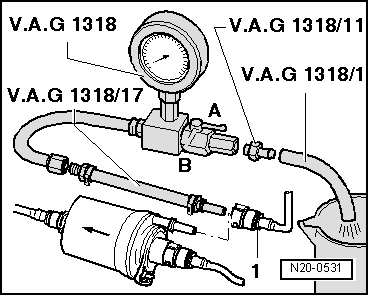

| Connect pressure tester -V.A.G 1318- using the adaptors -V.A.G 1318/17-as shown. |

| –

| Connect the Adapter -V.A.G 1318/1- to the Adapter -V.A.G 1318/11- of the pressure gauge and hold it in the measurement container. |

| –

| Open cut-off tap on pressure gauge. The lever then points in through flow direction -A-. |

| –

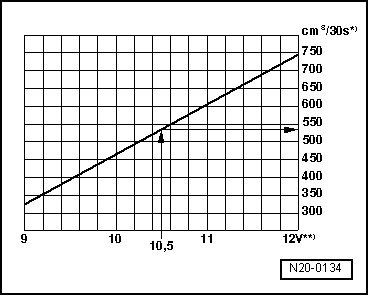

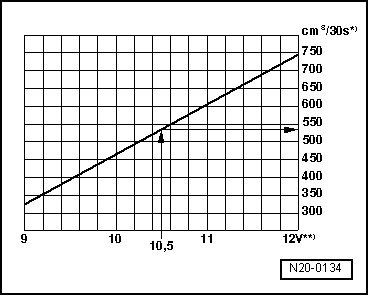

| Activate the V.A.G 1348 remote control -V.A.G 1348/3A-. In doing so, slowly close the shut-off cock arrow until pressure gauge indicates a pressure of 3 bar. From here on, do not change position of shut-off tap. |

| –

| Activate remote control again for 30 seconds. Compare the flow with the first value measured. |

| If the minimum delivery rate is now attained: |

| If the minimum delivery rate is again not attained: |

| –

| Remove the fuel delivery unit and check the strainer filter for soiling → Chapter. |

| Only when up to now no fault has been detected: |

|

|

|

Note

Note

Note

Note