Leon Mk1

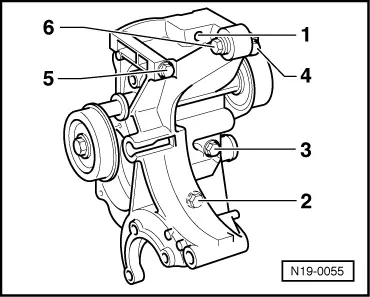

| Removing and installing coolant pump and compact bracket |

| 1 - | 25 Nm |

| q | Use counter-hold -T20018- to loosen and tighten |

| 2 - | Belt pulley |

| q | For coolant pump |

| 3 - | 10 Nm |

| 4 - | Coolant pump |

| q | Check for ease of movement |

| 5 - | O-ring |

| q | Renew |

| 6 - | 25 Nm |

| q | Do not tighten until the injection pump is bolted tightly to the console |

| q | Note tightening sequence → Fig. |

| 7 - | Compact bracket |

| q | For coolant pump, coolant thermostat, ribbed belt tensioning roller, alternator and P.A.S. vane pump |

| 8 - | 25 Nm |

| q | Note tightening sequence → Fig. |

| 9 - | Coolant thermostat |

| q | Checking: heat-up thermostat in water |

| q | Opening commences approx. 85 °C |

| q | Ends approx. 105 °C |

| q | Opening lift min. 7 mm |

| 10 - | Connection |