Leon Mk1

|

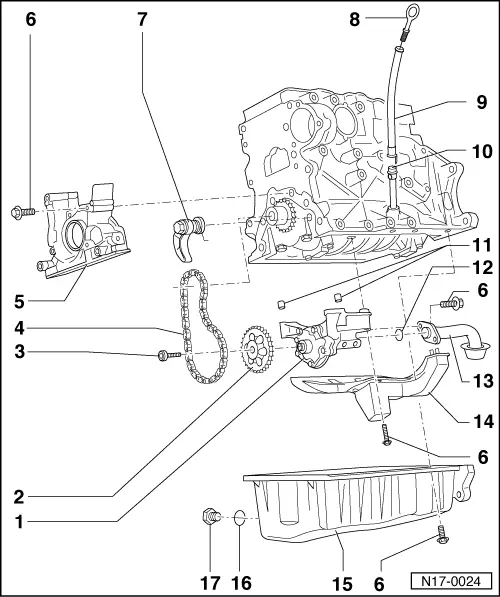

| 1 - | Oil pump |

| q | With 12 bar discharge valve |

| q | Before fitting, check the presence of the two adjustment sleeves for centring: oil pump/engine block |

| q | Should there be streaks on the sliding surfaces and toothed wheels: replace |

| 2 - | Chain wheel |

| 3 - | 25 Nm |

| 4 - | Chain |

| 5 - | Sealing flange |

| q | With seal |

| q | Removal and refitting → Chapter |

| q | Fit with silicon based sealant -D 176 404 A2- → Chapter |

| q | Note the different versions |

| q | PTFE seal without interior spring |

| q | Replace the crankshaft seal, pulley side → Chapter |

| 6 - | 15 Nm |

| 7 - | Chain tensioner with tensioner rail, 15 Nm |

| q | On fitting, pretension the spring and fix |

| 8 - | Oil level dipstick |

| q | The oil level must not lie above the max. mark! |

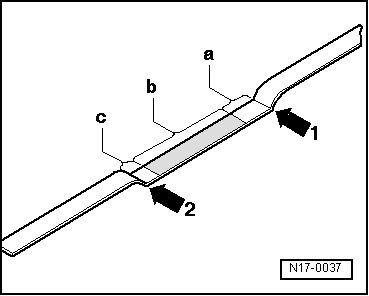

| q | Marks → Fig. |

| 9 - | Filling funnel |

| q | Remove if evacuating the oil by absorption |

| 10 - | Guide pipe |

| 11 - | Adjustment sleeves |

| 12 - | O ring |

| q | Replace |

| 13 - | Sucking pipe |

| q | Clean the filter if dirty |

| 14 - | Anti wave panel |

| 15 - | Oil pan |

| q | Before fitting, clean the sealing surface |

| q | Fit with silicon based sealant -D 176 404 A2- → Chapter |

| 16 - | Seal ring |

| q | Replace |

| 17 - | Oil purging bolt, 30 Nm |