Leon Mk1

|

|

|

|

|

|

|

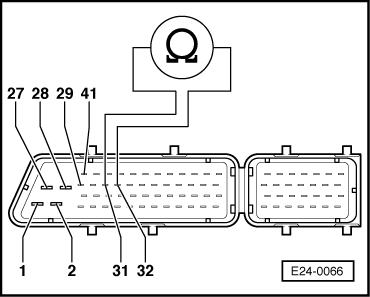

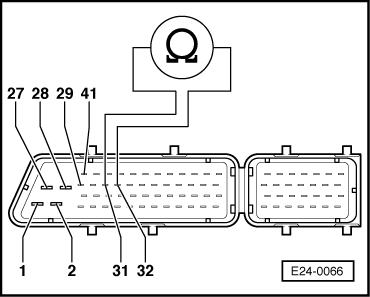

| Connector, contact | Connector, contact |

| 31 | 32 |

| Specification: 60 … 72 Ω | |

|

|

|

|

|

|

|

|

| Connector, contact | Connector, contact |

| 31 | 32 |

| Specification: 60 … 72 Ω | |

|